Loading ...

Loading ...

Loading ...

English

12

Three Year Limited Warranty

DEWALT

will repair or replace, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. This warranty does not cover part failure

due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call

1-800-4-

DEWALT

(1-800-433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. THIS LIMITED WARRANTY IS

GIVEN IN LIEU OF ALL OTHERS, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, AND EXCLUDES ALL INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow limitations on how long an implied warranty lasts or the

exclusion or limitation of incidental or consequential damages, so these limitations may not apply

to you. This warranty gives you specific legal rights and you may have other rights which vary in

certain states orprovinces.

90 DAY MOnEY BACK gUARAnTEE

If you are not completely satisfied with the performance of your

DEWALT

Power Tool or Nailer

for any reason, you can return it within 90 days from the date of purchase with a receipt for a full

refund – no questionsasked.

lATin AMERiCA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained in the packaging, call

the local company or see website for warrantyinformation.

FREE WARning lABEl REPlACEMEnT: If your warning labels become illegible or are missing,

call 1-800-4-

DEWALT

(1-800-433-9258) for a freereplacement.

Register Online

Thank you for your purchase. Register your product nowfor:

• WARRAnTY sERViCE: Registering your product will help you obtain more efficient warranty

service in case there is a problem with yourproduct.

• COnFiRMATiOn OF OWnERshiP: In case of an insurance loss, such as fire, flood or theft,

your registration of ownership will serve as your proof ofpurchase.

• FOR YOUR sAFETY: Registering your product will allow us to contact you in the unlikely

event a safety notification is required under the Federal Consumer SafetyAct.

• Register online at www.dewalt.com

Repairs

WARNING: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (including power cord repairs, and brush inspection and replacement, when

applicable) should be performed by a

DEWALT

factory service center or a

DEWALT

authorized

service center. Always use identical replacementparts.

• Compatible Stands (DW7440RS, DW7451, DWE74911**)

• Dust extraction Y connector (contact your local dealer)

** The DWE74911 stand is ONLY compatible with the DWE7485 if purchased separately. When

purchased with the original DWE7491RS saw, the stand DOES NOT include the necessary

adapter brackets for theDWE7485.

Accessories

WARNING: Since accessories, other than those offered by

DEWALT

, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the

risk of injury, only

DEWALT

recommended accessories should be used with thisproduct.

Recommended accessories for use with your tool are available at extra cost from your local dealer

or authorized service center. If you need assistance in locating any accessory, please contact

DEWALT

call 1-800-4-

DEWALT

(1-800-433-9258) or visit our website: www.dewalt.com.

Cleaning

WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week.

To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when

performingthisprocedure.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a

cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never

immerse any part of the tool into aliquid.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect

it from power source before making any adjustments or removing/installing

attachments or accessories. An accidental start-up can causeinjury.

3. Feed the workpiece through until the edge of the material reaches the front edge of the saw

tabletop.

4. Continue feeding the material using the push block

58

until the cut iscomplete.

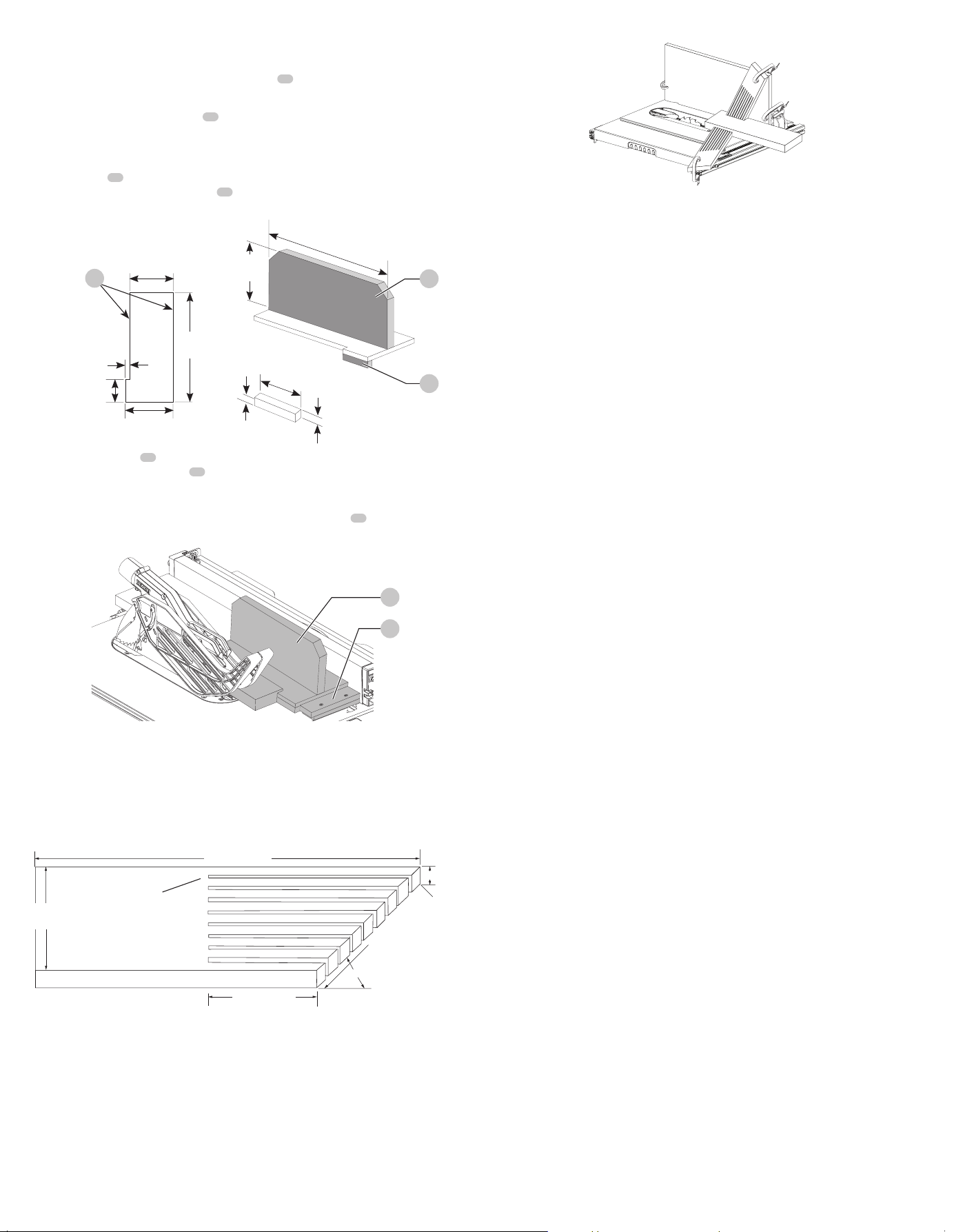

Push Block (Fig. BB, CC)

iMPORTAnT: Only use the push block

58

with the narrow rip auxiliary fence, refer to Narrow

Rip Auxiliary Fence. The push block should be used once the material being cut reaches the saw

tabletop.

1. Construct a push block using the diagram in FigureBB.

nOTE: Edges

45

must beparallel.

iMPORTAnT: The over hanging edge

47

(Fig. BB) MUST be square. An uneven lip could

cause the push block to slip or push the material away from thefence.

12

"

(305mm)

Fig. BB

2-1/2" (64mm)

5"

(127 mm)

1/2"

(12.7 mm)

4-3/4"

(121 mm)

12"

(305 mm)

1/2"

(12.7 mm)

5-1/4"

(133 mm)

2-1/2"

(64 mm)

1/2"

(12.7 mm)

58

45

47

2. Place the push block

58

(Fig. CC) behind the material and ensure the lip of the block is flush

to the narrow rip auxiliary fence

55

.

3. Once the push block is in place, continue feeding the material until the cut is complete

making sure the push block remains flush to the narrow rip auxiliary fence at alltimes.

iMPORTAnT: The narrow rip auxiliary fence and the over hanging edge

47

(Fig. BB) should both

be the samethickness.

Fig. CC

58

55

Featherboard Construction (Fig. DD, EE)

Featherboards are used to keep the work in contact with the fence and table, and help prevent

kickbacks. Dimensions for making a typical featherboard are shown in Figure DD. Make

the featherboard from a straight piece of wood that is free of knots and cracks. Clamp the

featherboard to the fence and table so that the leading edge of the featherboard will support the

workpiece until the cut is complete (Fig. EE). An 8" (203mm) high flat board can be clamped to

the rip fence and the featherboard can be clamped to the 8" (203mm) highboard.

60º

Fig. DD

24" (610mm)

5" (127mm)

3/4"

(20mm)

The kerf should

be about 1/4"

(6.4mm) apart

4"

(102mm)

WARNING: Use featherboards for all non-through-cutting operations where the blade

guard assembly, anti-kickback assembly and riving knife cannot be used. Always replace

the blade guard assembly, anti-kickback assembly and riving knife when the non-

through-cutting operation is complete. Make sure the featherboard presses only on the

portion of the workpiece in front of theblade.

Fig. EE

Loading ...

Loading ...

Loading ...