Loading ...

Loading ...

Loading ...

English

11

Non-Through-Compound Mitering

This is a combination of non-through-bevel crosscutting and non-through-mitering. Follow the

instructions for both non-through-bevel crosscutting and non-through-mitering.

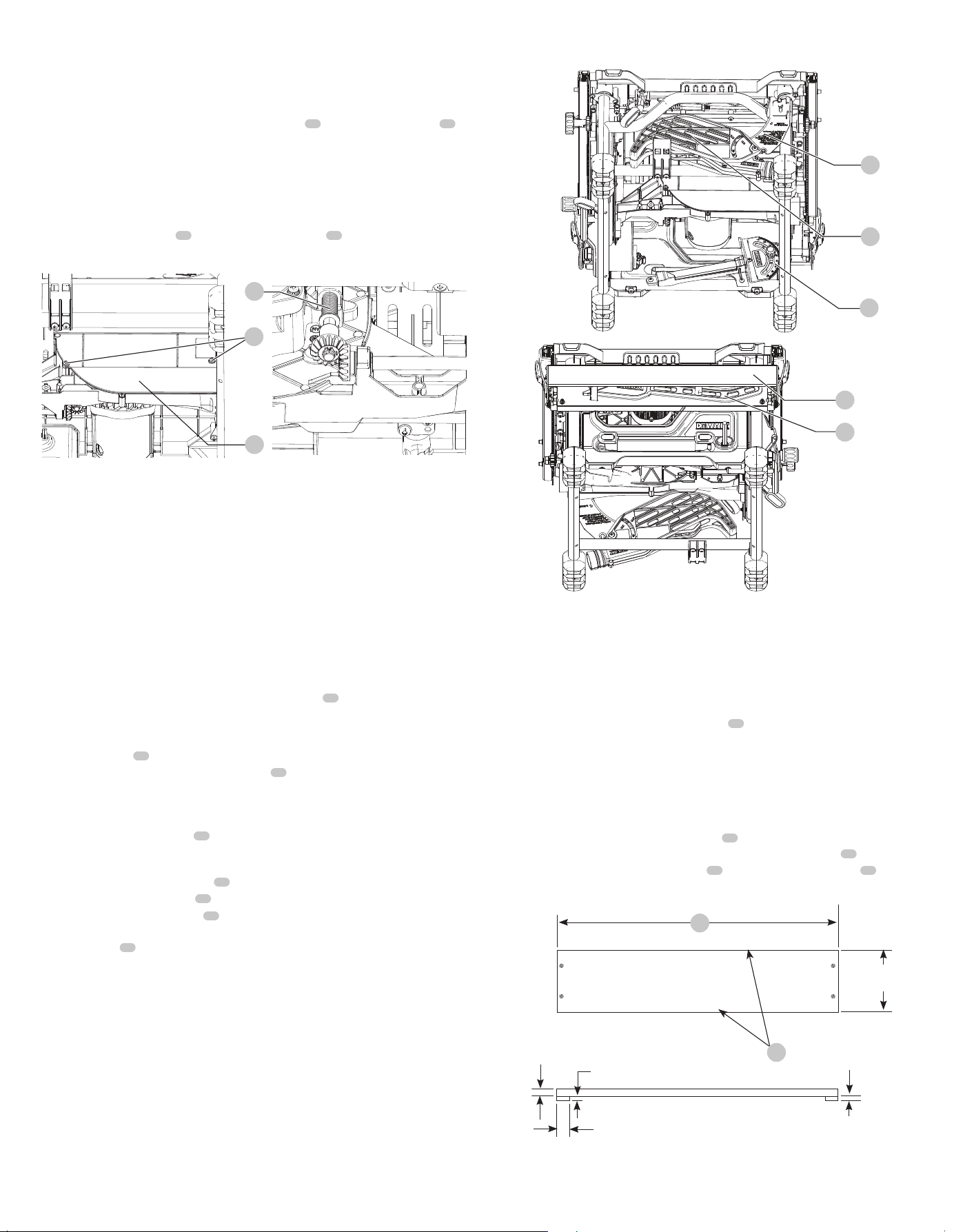

Dust Collection (Fig. A, X)

This table saw is equipped with a guard dust collection port

14

and a dust collection port

13

.

For best results, connect a vacuum to the port at the rear of the saw and on the guard using a Y

connector. The Y connector is available as an accessory at additional cost. Refer toAccessories.

NOTICE: Care should be taken to position hoses to not interfere with cuttingoperation.

WARNING: To prevent accidental start up, disconnect it from power source before cleaning

out dust collectionsystem.

1. Turn the saw on its side, so the bottom, open part of the unit isaccessible.

2. Open the dust access door

52

shown by removing 2 screws

53

and detaching the door.

Clean out the excess dust, and re-attach door, securing it with thescrews.

Fig. X

54

52

Fig. Y

53

Motor Overload and Power Loss Reset Switch

If power is interrupted by a circuit breaker trip, or power is lost, the saw contains a power loss

reset switch feature that will automatically reset to OFF position.

Circuit breaker overload is often the result of a dull blade. Change your blade on a regular basis to

avoid tripping your breaker. Disconnect the saw from power source and check your blade before

re-setting the circuit breaker and continuing to saw.

Lubrication (Fig. Y)

1. All motor bearings are permanently lubricated at the factory and no additional lubrication

isneeded.

2. The height adjustment screw may require periodic cleaning and lubrication. If you have

difficulty raising or lowering the blade:

a. Unplug the saw.

b. Turn the saw on its side, so the bottom, open part of the unit isaccessible.

c. Clean and lubricate the height adjustment screw threads

54

on the underside of this saw

with general purpose grease. Refer to FigureY.

Storage (Fig. A, Z)

1. Attach push stick

20

tofence.

2. Depress the stem on the anti-kickback assembly

12

to allow the assembly to slide from the

riving knifeslot.

3. Position anti-kickback assembly into storage as shown. While depressing stem, slide the anti-

kickback assembly across the storage bracket and release pin to lock intoplace.

4. Remove blade guard assembly

11

. Refer to Installing/Removing the Blade Guard

Assembly and Riving Knife. Place blade guard assembly into holder as shown, then turn lock

1/4 turn to lock inplace.

5. Slide closed end of blade wrenches

19

into catch then secure in place with wingnut.

6. Insert guide bar of miter gauge

10

into pocket until it bottomsout.

7. Non-through-cutting riving knife

21

can be installed on the saw (working position) or stored

along with the blade guard assembly as shown.

8. To store fence

16

, snap work support in stored position. Remove fence from rails. Reattach

fence upside down on left side of saw. Pivot fence lock latches tosecure.

Fig. Z

11

10

21

20

16

Transporting (Fig.A)

WARNING: To reduce the risk of serious personal injury, turn unit off and disconnect

it from power source before transporting the saw. An accidental start-up can

causeinjury.

WARNING: Always transport the machine with the upper blade guardfitted.

• Before transporting, lock the fence in place, lower the blade and lock thebevel.

• Always carry the machine using the carry handles

22

.

Accessory Construction for Alternative Operation Methods

(If not equipped with narrow ripping fence)

Narrow Rip Auxiliary Fence (Fig. AA–CC)

The narrow rip auxiliary fence should be used for a rip measuring 2" (51mm) or narrower. This

fence will allow the guard to remain on the saw when completing narrow ripping. This fence will

provide ample space for proper use of a push block (

58

, see Push Block).

1. Follow the diagram in Figure DD to construct the narrow rip auxiliary fence

55

.

nOTE: The length should be cut to fit the length

56

of the saw table top and sides

57

must

beparallel.

3/8"

(9.5 mm)

1"

(25 mm)

1/2"

(12.7 mm)

Fig. AA

4-3/4"

(121 mm)

3/8"

(9.5mm)

56

57

2. After the narrow rip auxiliary fence is constructed, slip it over the saw table top and place it

flush to the fence as shown in FigureFF.

Loading ...

Loading ...

Loading ...