Loading ...

Loading ...

Loading ...

English 9

CAUTION

• Use a conduit for field wiring.

• Outside the unit, make sure the low voltage wiring (i.e. for the

remote controller wire, between units, etc.) and the high voltage

wiring do not pass near each other, keeping them at least

2 in. (50 mm) apart.

Proximity may cause electrical interference, malfunctions, and

breakage.

• Be sure to connect the power supply wiring to the power supply wir-

ing terminal block and secure it as described in “7-3 How to con-

nect the power supply wiring”.

• Transmission wiring should be secured as described in “7-4 Trans-

mission wiring connection procedure”.

• Secure wiring with clamp (accessory) to avoid contact with piping.

• Make sure the wiring and the front panel do not stick up above the

structure, and close the panel firmly.

(Refer to figure 22)

1. Fuse/Breaker

2. Power supply

3. Outdoor unit

4. 16V

5. 208/230V

6. Indoor unit

7. Remote controller

8. Ground wire

7-2 How to lay the power supply wiring and trans-

mission wiring

Let the power supply wiring and transmission wiring with a conduit pass

through one of the knockout on the front or side cover, and let the trans-

mission wiring with a conduit pass through another knockout.

• For protection from uninsulated live parts, thread the power supply

wiring and the transmission wiring through the included insulation

tube and secure it with the included clamp.

Precautions knockout

• Open the knockout with a hammer or the like.

•

After knocking out the knockout, we recommend you remove burrs in the knockout and paint

the edges and areas around the edges using the repair paint to prevent rusting.

• When passing wiring through knockout, make sure there are no

burrs, and protect the wiring with protective tape.

(Refer to figure 23)

1. Stop valve fixing plate

2. Power supply wiring (including ground wire) or transmission

wiring.

3. Back of unit

4. Knockout

5. Side of unit

6. Front of unit

7. Terminal block

8. Control Box

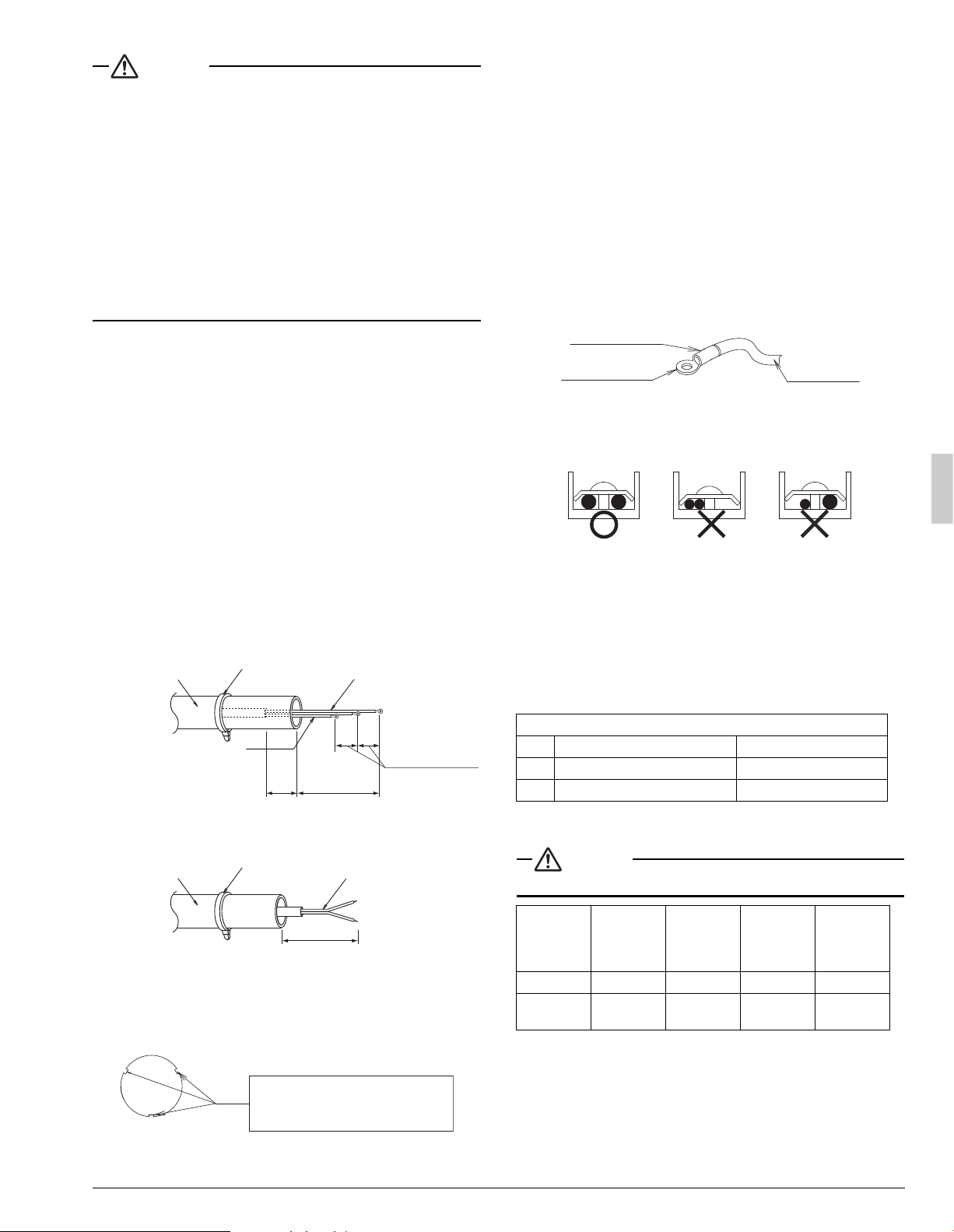

<Precautions when laying power supply wiring>

• Wiring of different thicknesses cannot be connected to the power

supply terminal block.

(Slack in the power supply wiring may cause abnormal heat.)

• Use sleeve-insulated round pressure terminals for connections to

the power supply terminal block. When none are available, connect

wire of the same diameter to both sides, as shown in the figure.

Follow the instructions below if the wiring gets very hot due to

slack in the power supply wiring.

• For wiring, use the designated power wire and connect firmly, then

secure using the included clamping material to prevent outside pres-

sure being exerted on the terminal board.

• Use an appropriate screwdriver for tightening the terminal screws.

A screwdriver with a small head will strip the head and make proper

tightening impossible.

• Over-tightening the terminal screw may break it.

See the table below the tightening torque of the terminal screws.

7-3 How to connect the power supply wiring

CAUTION

Attach a circuit breaker or fuse.

Insulation tube

(accessory)

Clamp

(accessory)

Power supply

wiring

3 in. (75 mm)

2 in. (50 mm)

or more

5/8 in. (15.9 mm)

Insulation tube

(accessory)

Clamp

(accessory)

Transmission

wiring

3 in. (75 mm)

<Power supply wiring>

<Transmission wiring>

Ground wire

If small animals might enter the

unit, block the knockout with an

appropriate material (field supply).

Burr

Tightening torque (ft·lbf / N·m)

M5 Power supply terminal 1.76~2.15 / 2.39~2.91

M4 Shield ground 0.87~1.06 / 1.18~1.44

M3 Transmission wiring terminal block 0.58~0.72 / 0.8~0.97

Model

Phase and

frequency

Voltage

Maximum

overcurrent

protective

device

Minimum

circuit

ampacity

18·24 type

1~60Hz 208/230V 25A 16.5A

30·36·

42·48 type

1~60Hz 208/230V 35A 29.1A

Insulating sleeve

Round crimp-style

terminal

Electric Wire

Connect wires

of the same gauge

to both side.

Do not connect

wires of different

gauges.

Do not connect

wires of the same

gauge to one side.

Loading ...

Loading ...

Loading ...