Loading ...

Loading ...

Loading ...

4

- Australia

- New Zealand Only:

- UK Only:

Category: II

2H3P

(20, 37).

Flue Type: A

1.

* - Measure burner operating pressure at gas control valve outlet test point with one burner

operating at ‘High’ setting. Operating pressure is ex-factory set, through the appliance

regulator and not to be adjusted, apart from when converting between gases, if required.

(Refer to ‘Gas Conversion’ section for details).

GP8910GE/GEC GP8121GE/GEC GP8910GE/GEC GP8121GE/GEC

Heat Input (nett) 21 kW 28.5 kW 21 kW 28.5 kW

Gas Rate (nett) 2.22 m

3

/hr 3.02 m

3

/hr 1.63 kg/hr 2.21 kg/hr

Supply Pressure 20 mbar 37 mbar

Burner Operating Pressure (*) 8.2 mbar 26 mbar

Gas Connection

3

/

4

” BSP Male

GP8910GE/GEC GP8121GE/GEC GP8910GE/GEC GP8121GE/GEC

Input Rating (N.H.G.C.) 80 MJ/hr 108 MJ/hr 80 MJ/hr 108 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 2.75 - 4.50 kPa

Burner Operating Pressure (*) 0.90 kPa 2.6 kPa

Gas Connection ¾” BSP Male

GP8910GE/GEC GP8121GE/GEC GP8910GE/GEC GP8121GE/GEC

Input Rating (N.H.G.C.)

80 MJ/hr 108 MJ/hr 80 MJ/hr 108 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 2.75 - 4.50 kPa

Burner Operating Pressure (*) 0.90 kPa 2.6 kPa

Gas Connection ¾” BSP Male

25

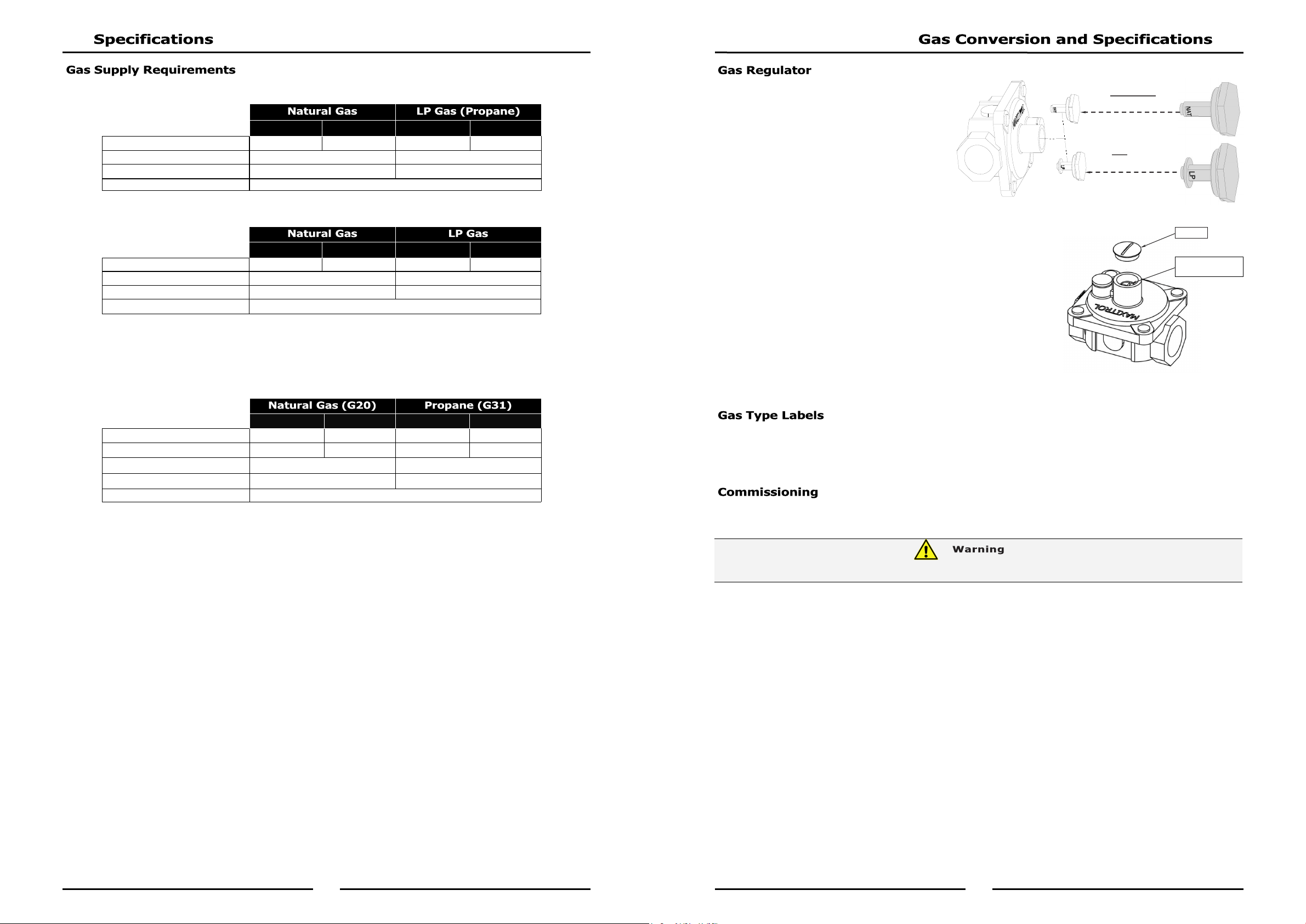

NOTE, Pin rotated

for Natural Gas

NOTE, Pin rotated

for LPG

- NAT Gas / LPG / Butane Only.

NOTE: Gas regulator supplied is

convertible between Natural Gas

and LP Gas, but it’s outlet

pressure is fixed ex-factory and

is NOT to be adjusted.

- Town Gas Only.

1. Remove slotted cap from regulator.

2. Turn ‘On’ gas supply and appliance.

3. Adjust pressure adjusting screw to achieve correct burner

operating pressure.

NOTE: Measure burner operating pressure at gas valve outlet

test point with burner operating at 'High Flame'

setting.

4. Verify operating pressure remains correct (Re-adjust

regulator if required).

5. Screw cap nut back onto regulator.

On completion of gas conversion, replace gas type labels located at:-

- Rear of unit, above gas connection.

- Beside rating plate.

Before leaving installation;

1. Check all gas connections for leakage using soapy water or other gas detecting equipment.

2. Carry out a ‘Commissioning’ check of appliance as shown in Installation Section of this manual.

3. Ensure any adjustments done to components that have adjustments / settings paint sealed are to be

re-sealed.

NOTE: If for some reason it is not possible to get the appliance to operate correctly, shut off the

gas supply and contact the supplier of this appliance.

DO NOT USE A NAKED FLAME TO CHECK FOR GAS LEAKAGES.

Pressure Adjusting

Screw

Cap Nut

Loading ...

Loading ...

Loading ...