Loading ...

Loading ...

Loading ...

- Water must be supplied to the appliance through a cold

water pipe that complies with hygiene standards and can

withstand the operating pressure.

Use the stainless steel hose supplied (Length 1.5 m) Do not

reuse old hoses. A 3 m hose is available as an optional

extra. This must be professionally installed.

A filter with a seal is located in the hose connector.

- A stopcock must be placed between the hose line and the

domestic water connection to cut off the water supply, if

necessary.

- All devices and equipment used to supply water must

comply with the regulations in force in the respective

country.

- Do not damage or kink the water supply line during installa-

tion.

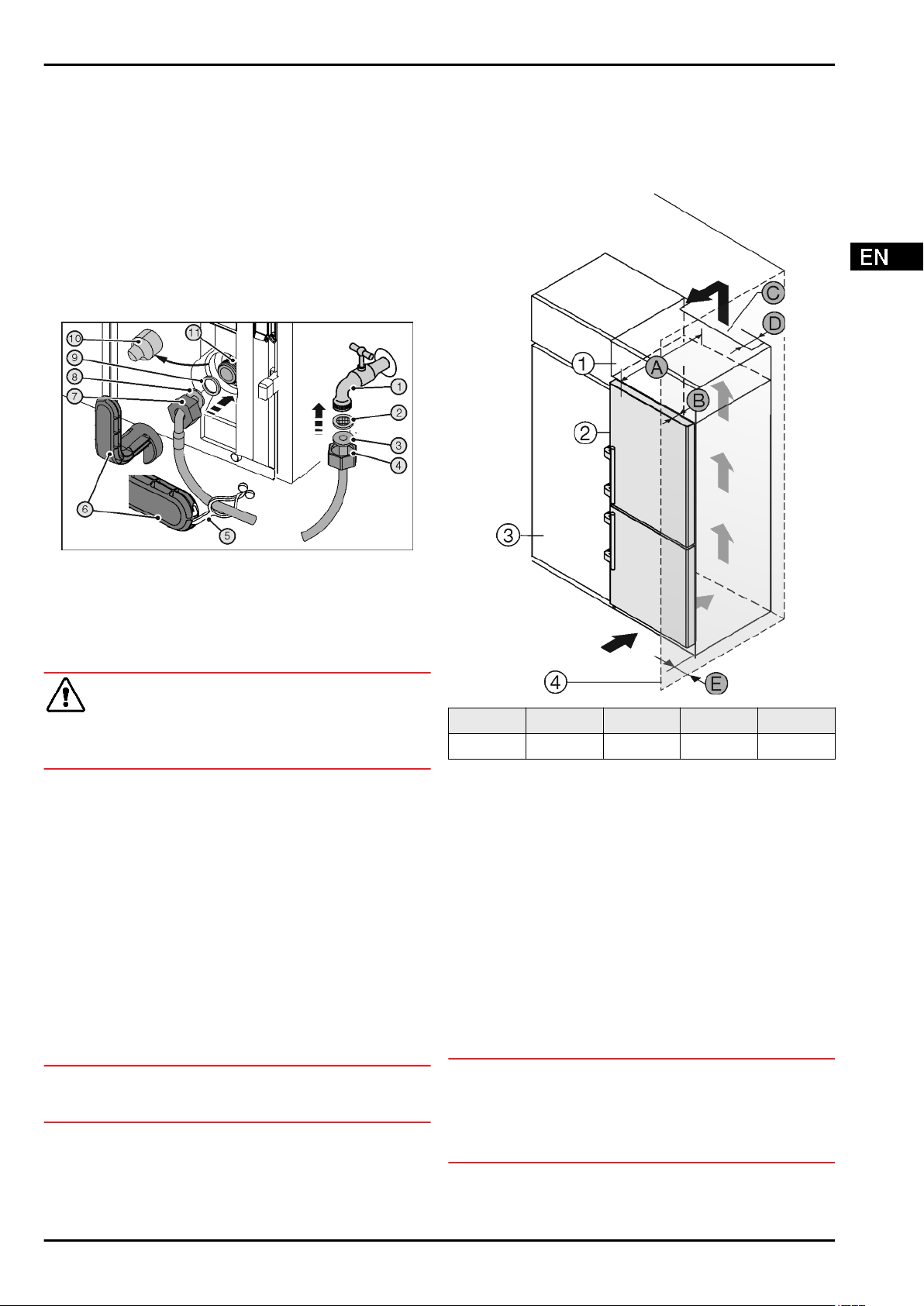

Fig. 44

The solenoid is at the bottom on the back of the appliance. It

has a metric R3/4 connecting thread.

For specialist staff:

The back of the appliance must be accessible to connect the

stainless steel hose:

WARNING

Risk of injury.

Cuts from a broken auxiliary tool

Fig. 44 (6)

.

u

Only use an auxiliary tool

Fig. 44 (6)

at room temperature.

u

Slide the nut

Fig. 44 (4)

over the straight end of the hose

Fig. 44 (3)

up to the end and secure.

u

Insert the filter

Fig. 44 (2)

into the nut

Fig. 44 (4)

.

w

The filter

Fig. 44 (2)

rests flat on the straight end of the hose

Fig. 44 (3)

and is easily retained.

u

Connect the nut

Fig. 44 (4)

to the cut-off valve

Fig. 44 (3)

with the filter resting on the straight end of the hose

Fig. 44 (2)

.

u

Open the water supply cut-off valve

Fig. 44 (1)

temporarily to

bleed the water pipe and fill it with water. Keep the hose in a

bucket.

u

Remove the cover

Fig. 44 (10)

.

u

Slide the nut

Fig. 44 (7)

over the angled end of the hose

Fig. 44 (8)

up to the end and secure.

u

Moisten the seal

Fig. 44 (9)

and push into the nut

Fig. 44 (7)

on the end of the angled hose

Fig. 44 (8)

.

w

The seal

Fig. 44 (9)

lies flat on the angled end of the hose

Fig. 44 (8)

and is easily retained.

NOTICE

Risk of damaging the threads of the solenoid.

u

Locate the nut carefully and screw onto the thread.

u

Connect the nut

Fig. 44 (7)

to the solenoid

Fig. 44 (8)

with

the seal resting on the

Fig. 44 (9)

angled end of the hose

Fig. 44 (11)

.

u

Tighten connections with the auxiliary tool

Fig. 44 (6)

clock-

wise until the maximum torque is reached and the auxiliary

tool

Fig. 44 (6)

is overwound.

u

Open the water supply cut-off valve

Fig. 44 (1)

and check

the whole water system for leaks.

u

Hook the clip

Fig. 44 (5)

into the auxiliary tool

Fig. 44 (6)

and

fix it to the stainless steel pipe to store it.

4.5 Insertion into a row of kitchen units

Fig. 45

A [mm] B [mm]

C [cm

2

]

D [mm] E [mm]

665

x

65 Min. 300 Min. 50 Min. 46

x

If wall spacers are used, the dimensions increase by 15 mm

(see 4.2) .

The dimensions apply for an opening angle of 90 °. Spacing

angles will vary according to the opening angle.

You can purchase a kit to limit the door opening angle to 90° on

soft closing appliances. Please contact our customer service

team.

The appliance can be built into kitchen units. A top cupboard

Fig. 45 (2)

can be added above the appliance in order to bring

the appliance

Fig. 45 (1)

up to the height of the fitted kitchen

units.

The appliance can be installed right next to the kitchen cabinet

Fig. 45 (3)

. The appliance must stick out by the depth

Fig. 45 (B)

from the front of the cabinet so that the doors can be

opened fully. The appliance may protrude further depending on

the depth of the kitchen cabinets and whether wall spacers are

used.

NOTICE

Danger of overheating due to insufficient air ventilation!

The compressor may be damaged if there is insufficient air

ventilation.

u

Take care to ensure adequate air ventilation.

u

Observe the ventilation requirements.

Ventilation requirements:

Putting into operation

* Depending on model and options 17

Loading ...

Loading ...

Loading ...