Loading ...

Loading ...

Loading ...

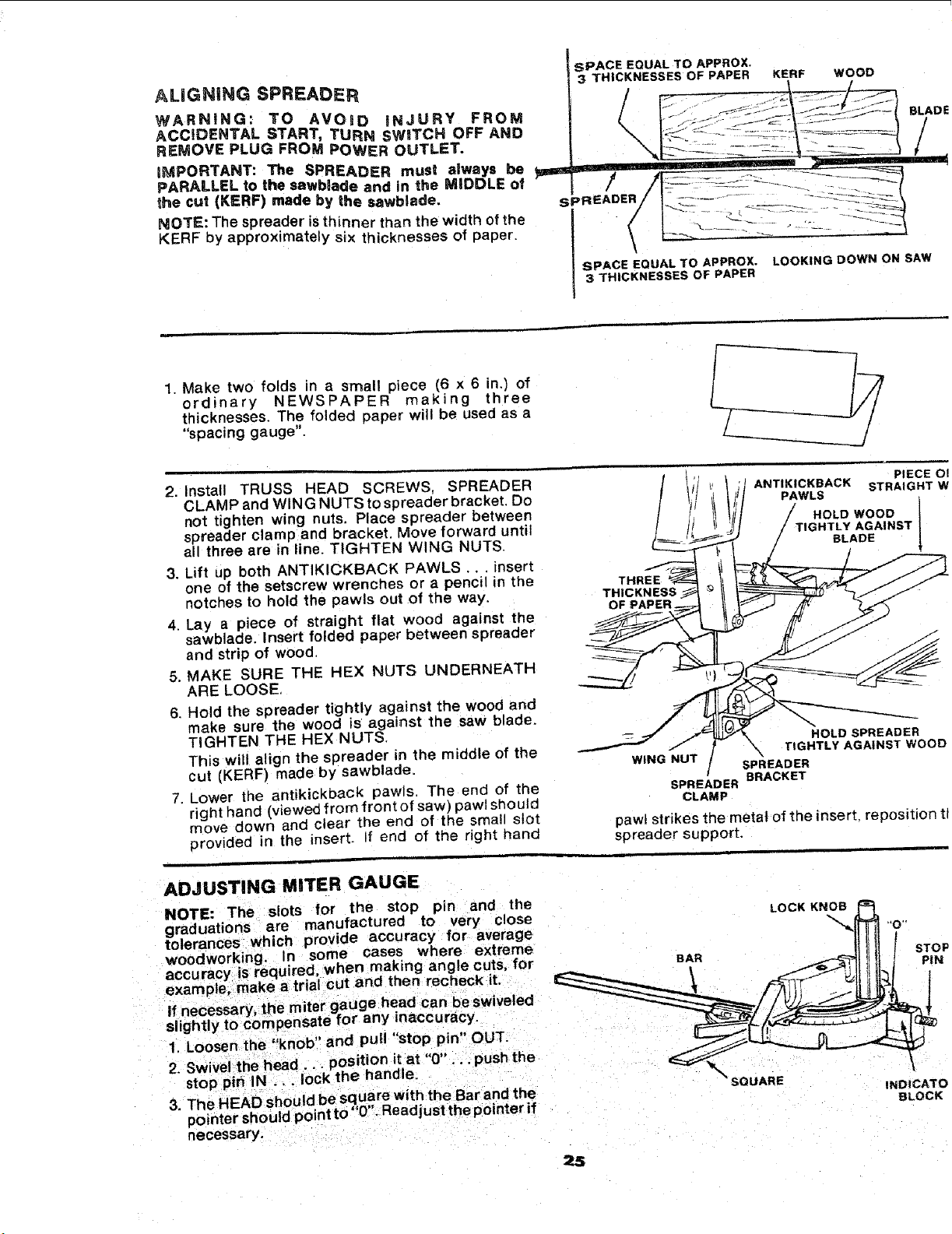

sPACE EQUAL TO APPROX,

3 THICKNESSES OF PAPER KERF WOOD

.- _ J _:_._ ,_ BLADE

WARNING: AVORD iNJURY .f._-. _..... _.-:L ....

ACCIDENTAL START, TURN SWITCH OFF AND , "_" _ -- ...................... -

REMOVE PLUG FROM POWER OUTLET. \._[_'C:3;:.:CiC_ -- _

iMPORTANT: The SPREADER must always be y=am _--

PARALLEL to the sawb,ade and in the MIDDLE of - i!__i__----__

the cut (KERF) made by the sawblade, sPR _._ ........ _ :___:

NOTE: The spreader is thinner than the width of the _/ l_]i!i "'z2 _._

KERF by approximately six thicknesses of paper.

SPACE EQUAL TO APPROX. LOOKING DOWN ON SAW

3 THIC KN ESSES OF PAPER

1. Make two folds in a small piece (6 x 6 in,) of

ordinary NEWSPAPER making three

thicknesses. The folded paper will be used as a

"spacing gauge".

2, Install TRUSS HEAD SCREWS, SPREADER

CLAM P and WING NUTS to spreader bracket. Do

net tighten wing nuts. Place spreader between

spreader clamp and bracket. Move forward until

all three are in line. TIGHTEN WING NUTS.

3. Lift up both ANTIKICKBACK PAWLS ... insert

one of the setscrew wrenches or a pencil in the

notches to hold the pawls out of the way.

4. Lay a piece of straight flat wood against the

sawblade. Insert folded paper between spreader

and strip of wood.

5, MAKE SURE THE HEX NUTS UNDERNEATH

ARE LOOSE,

6. Hold the spreader tightly against the wood and

make sure the wood is against the saw blade.

TIGHTEN THE HEX NUTS.

This will align the spreader in the middle of the

cut (KERF) made by sawblade.

7. Lower the antikickback pawls The end of the

right hand (viewed from front of saw) pawl should

move down and clear the end of the small slot

provided in the insert. If end of the right hang

/ ;1ANT,K,CKBACK

t / _ |/[! PAWLS

t t ft ,J/ 1 .OLD*OOD

J t, I_ _/ t TIGHTLYAGAINSTI

_. _ _ HOLD SPREADER

_ F _ TIGHTLY AGAINST WOOD

WING NUT I

/ SPREADER

BRACKET

SPREADER

CLAMP

pawt strikes the metal of the insert, reposition tl

sp reader support.

ADJUSTING MITER GAUGE

NOTE: The slots for the stop pin and the

graduations are manufactured to very close

tolerances which provide accuracy for average

woodworking. In some cases where extreme

accuracy is required, when making angle cuts, for

example, make a trial cut and then recheck it.

, ' pin" OUT.

1, Loosen the "knob and pull stop

INDICATO

BLOCK

necessary,

Loading ...

Loading ...

Loading ...