Loading ...

Loading ...

Loading ...

3, The rip fence must be PARALLEL with the

sawblade and miter Gauge grooves Move

fence until it is along side of groove. E)o NOT

LOCK IT. It sPiou/d be parallel to groove, If it rs

not;

A. Loosen the two "Hex Head Screws."

B. Hold fence head tightly against bar.. move end

of fence so that it is parallel with groove.

C. Alternately tighten the screws,

HEX SCREWS

FENCE HEAD

\

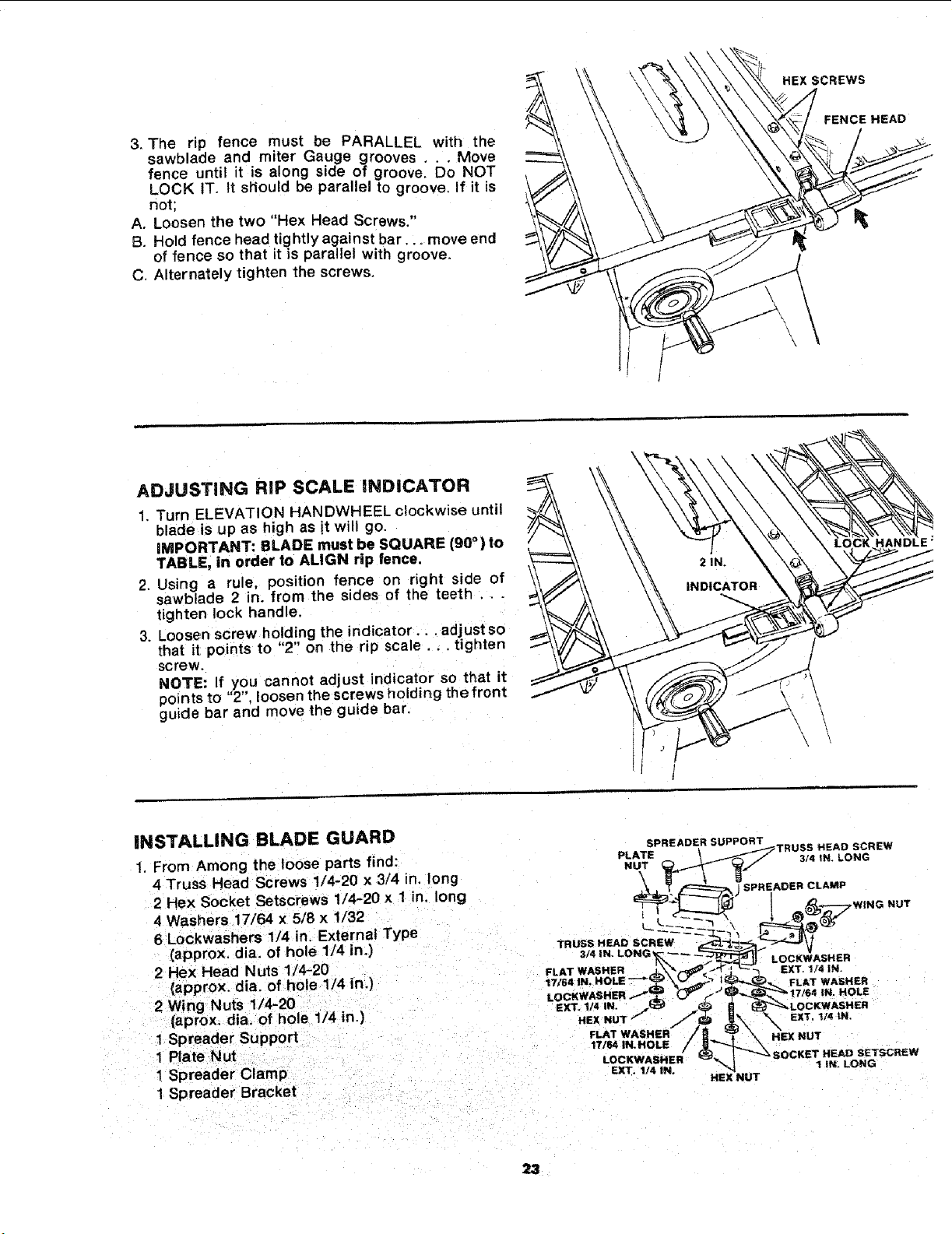

ADJUSTING RiP SCALE iNDiCATOR

1. Turn ELEVATION HANDWHEEL clockwise until

blade is up as high as it will go.

IMPORTANT: BLADE must be SQUARE (90° ) to

TABLE, in order to ALIGN rip fence,

2. Using a rule, position fence on right side of

sawblade 2 in. from the sides of the teeth...

tighten lock handle,

3. Loosen screw holding the indicator.., adjust so

that it points to "2" on the rip scale.., tighten

screw.

NOTE: If you cannot adjust indicator so that it

poin ts to "2", loosen the screws holding the front

guide bar and move the guide bar.

\

\

iNSTALLING BLADE GUARD

1. From Among the loose parts find:

4 Truss Head Screws 1/4-20 x 3/4 in. long

2 Hex Socket Setscrews 1/4-20 x 1 in. long

4 Washers 17/64 x 5/8 x 1/32

6 Lockwashers 1/4 in. External Type

(approx, die. of hole 1/4 in.)

2 Hex Head Nuts 1/4-20

{approx. die. of hole 1/4 in.)

2 Wing Nuts 1/4-20

(aprox, dia. of hole 1/4 in.)

1 Spreader Support

1 Plate Nut

1 Spreader Clamp

1 Spreader Bracket

SPREADER SUPPORT

PLATE

NUT

SPREAOER CLAMP

NUT

FLAT WASHER

17_41N

EXT. IN IN.

HEX NUT

/

FLAT WASHER

17/64 IN.HOLE

EXT. 1/4 IN.

HEX NUT

EXT. 1/4 IN.

FLAT WASHER

IN. HOLE

EXT, !/4 tN.

NUT

,OCKET HEAD SETSCREW

1 If_. LONG

23

Loading ...

Loading ...

Loading ...