Loading ...

Loading ...

Loading ...

Part Number 550-142-300/0520

47

CGa Series 3 Gas-Fired Water Boiler — Boiler Manual

Service & maintenance – annual start-up (cont.)10b

❏ Cleaning boiler heating surfaces (continued)

6. Remove radiation plates hanging between sections.

7. Remove burners from base. Brush and vacuum burners to

remove all dust and lint. Verify that all burner ports are free

of debris.

8. Place newspapers in base of boiler to collect soot.

9. Clean between sections with wire flue brush.

10. Remove newspaper and soot. Vacuum or brush base and

surrounding area.

11. Reinstall radiation plates.

12. Replace collector box/transition assembly. Seal with sealant.

Obtain gas-tight seal to prevent flue gas spillage and carbon

monoxide emissions, resulting in severe personal injury or

death.

13. Replace insulation and jacket top panel.

14. Start up boiler following Section

6 of this manual and the

boiler Operating instructions (Section 9b). Excessive sooting

indicates improper gas combustion. If found, check for proper

combustion and make any necessary adjustments.

Before troubleshooting:

1. Have the following items:

a. Voltmeter that can check 120 VAC and 24 VAC.

b. Microammeter with a minimum scale range of

0-25.

c. Continuity checker.

d. U-tube manometer.

2. Check for 120 VAC (minimum 102 VAC to maximum

132 VAC) to boiler.

3. Make sure thermostat is calling for heat and contacts

(including appropriate zone controls) are closed. Check

for 24 VAC between thermostat wire nuts and ground.

Troubleshooting — components11a

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Never jumper (bypass) rollout thermal

fuse element or any other device except for

momentary testing as outlined in Trouble-

shooting Charts

. Severe personal injury,

death or substantial property damage can

result.

Burner access panel must be in position

during boiler operation to prevent mo-

mentary flame rollout on ignition of main

flame. Severe personal injury or substantial

property damage will result.

See pages 48 through 56 for additional

troubleshooting information.

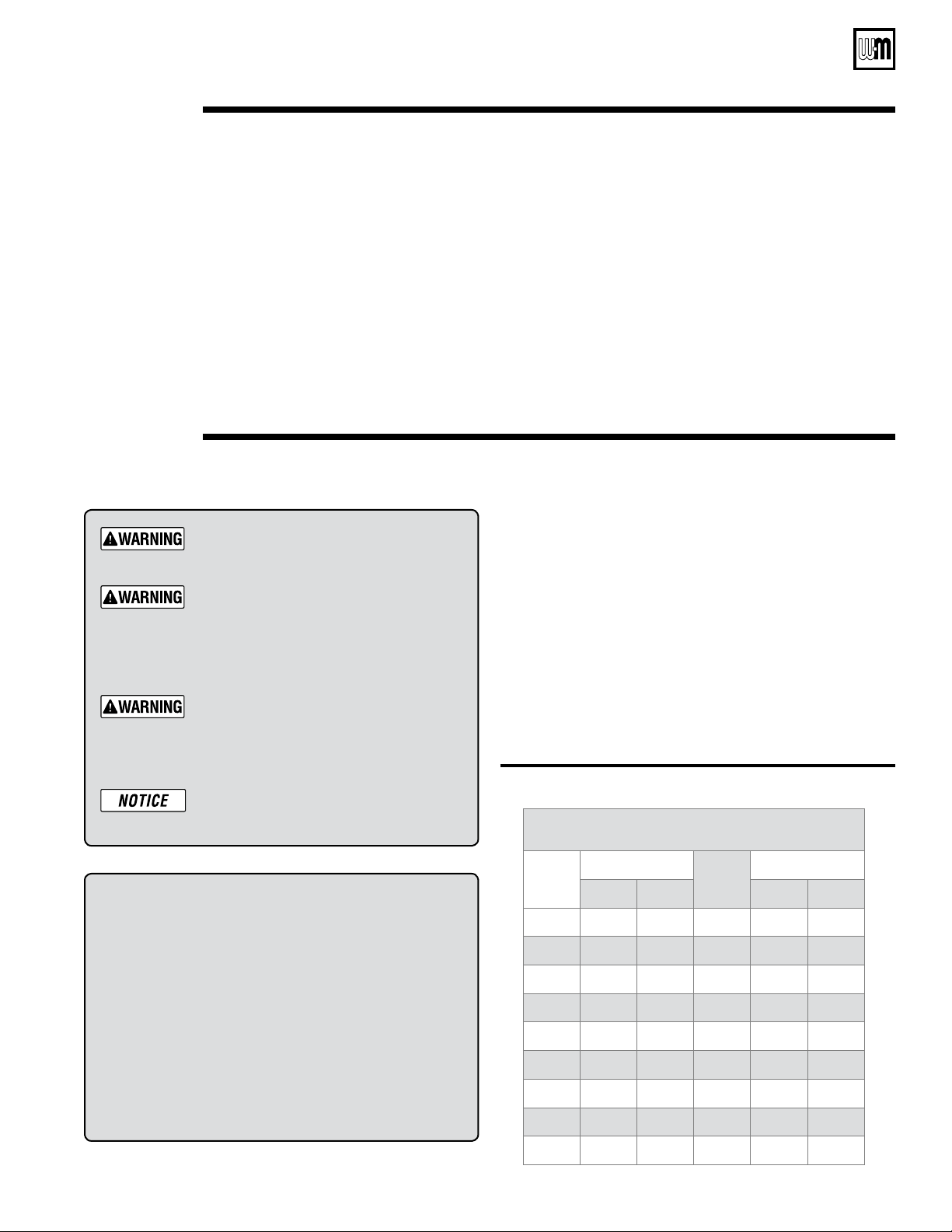

Sensor resistance values

Temp

(°F)

Sensor ohms

Temp

(°F)

Sensor ohms

Min Max Min Max

32

34265 37871

120

4517 4992

40

27834 30764

130

3698 4088

50

21630 23907

140

3043 3364

60

16944 18727

150

2517 2782

70

13372 14780

160

2091 2311

80

10629 11747

170

1744 1928

90

8504 9399

180

1461 1615

100

6847 7568

190

1229 1359

110

5545 6129

200

1038 1147

Temperature/LWCO sensor

1. The boiler temperature/LWCO sensor is a resistance-type

device.

2. The Table 7, below shows the correct value for the sensor at

various temperatures.

3. Use the resistance values at 32°F, 60°F, 70°F and 212°F to

measure the sensor resistance at known temperatures (ice

point, room temperature and sea level boiling point). For ice

point and boiling point, insert the sensor in water at that tem-

perature. Use an ohmmeter to read resistance value between

thermister # and thermistor common. See Figure 30, page 50,

for sensor plug details.

Table 7 Temperature/LWCO sensor resistance values

Loading ...

Loading ...

Loading ...