Loading ...

Loading ...

Loading ...

Due to our policy of continuous product innovation, some specications may change without notication.

©

LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG ” is a registered trademark of LG Corp.

60 | REFRIGERANT DESIGN

Single Zone Mega Wall Mounted Engineering Manual

INSTALLATION & LAYOUT BEST PRACTICES

Refrigerant Piping System Layout

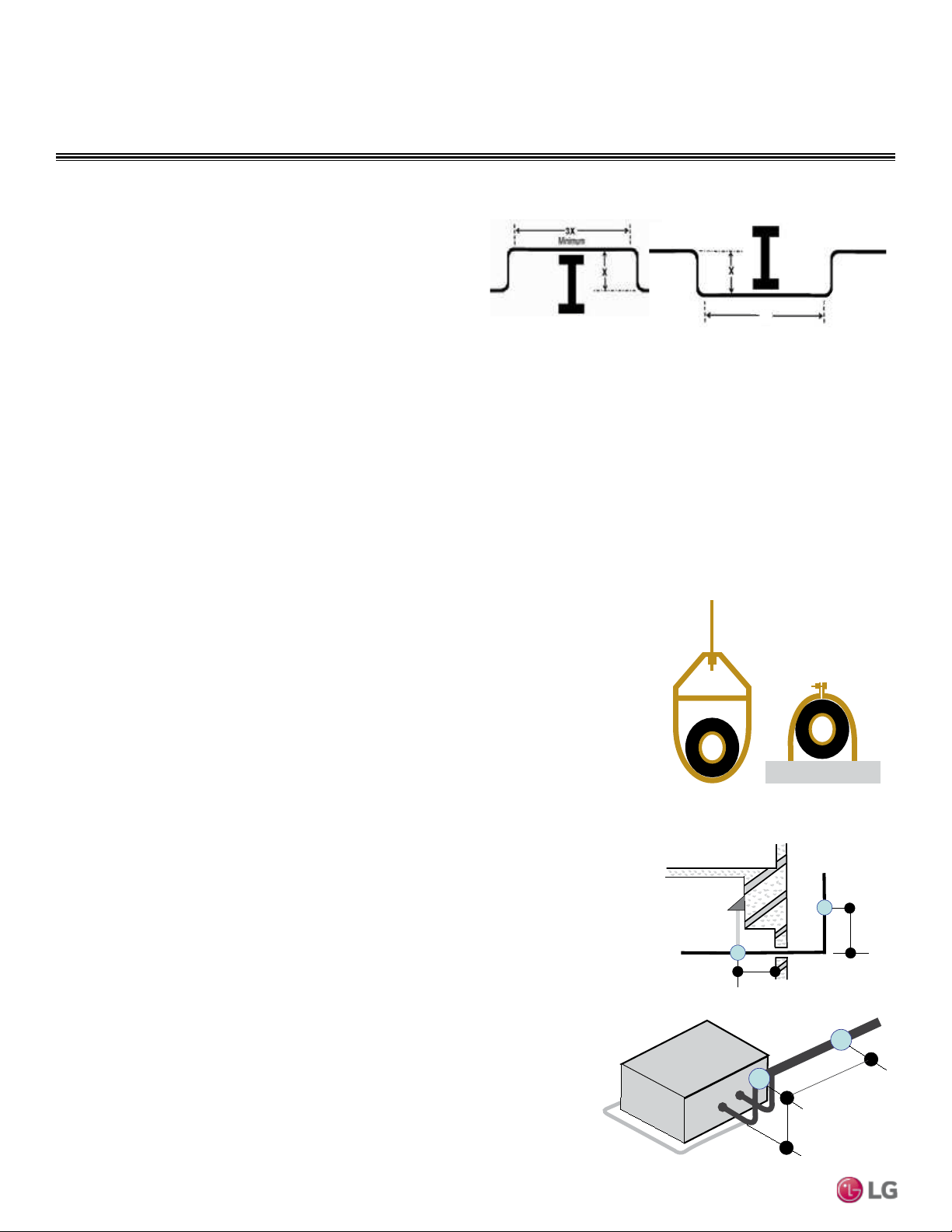

Figure 32: Installing Piping Above and Below an Obstacle

Above an obstacle.

3X

Below an obstacle.

Minimum

Obstacles

When an obstacle, such as an I-beam or concrete T, is in the path

of the planned refrigerant pipe run, it is best practice to route the

pipe over the obstacle. If adequate space is not available to route

the insulated pipe over the obstacle, then route the pipe under the

obstacle. In either case, it is imperative the horizontal section of pipe

above or below the obstacle be a minimum of three (3) times greater

than the longest vertical rise (or fall) distance (Figure 32).

No Pipe Size Substitutions

Using a different size is prohibited and may result in a system malfunction or failure to work at all.

In-line Refrigeration Components

Components such as oil traps, solenoid valves, filter-dryers, sight glasses, tee fittings, and other after-market accessories are not permitted

on the refrigerant piping system between the outdoor unit and the indoor unit. Single Zone Mega Inverter Wall Mounted air-source systems

are provided with redundant systems that assure oil is properly returned to the compressor. Sight-glasses and solenoid valves may cause

vapor to form in the liquid stream. Over time, dryers may deteriorate and introduce debris into the system. The designer and installer should

verify the refrigerant piping system is free of traps, sagging pipes, sight glasses, filter dryers, etc.

Pipe Supports

A properly installed pipe system should be adequately supported

to avoid pipe sagging. Sagging pipes become oil traps that lead to

equipment malfunction.

Pipe supports should never touch the pipe wall; supports shall be

installed outside (around) the primary pipe insulation jacket (see

Figure 33). Insulate the pipe first because pipe supports shall be

installed outside (around) the primary pipe insulation jacket. Clevis

hangers should be used with shields between the hangers and

insulation. Field provided pipe supports should be designed to

meet local codes. If allowed by code, use fiber straps or split-ring

hangers suspended from the ceiling on all-thread rods (fiber straps

or split ring hangers can be used as long as they do not compress

the pipe insulation). Place a second layer of insulation over the pipe

insulation jacket to prevent chafing and compression of the primary

insulation within the confines of the support pipe clamp.

A properly installed pipe system will have sufficient supports to avoid

pipes from sagging during the life of the system. As necessary,

place supports closer for segments where potential sagging could

occur. Maximum spacing of pipe supports shall meet local codes.

If local codes do not specify pipe support spacing, pipe shall be

supported as follows:

• Maximum of five feet (5′) on center for straight segments of pipe up

to 3/4" outside diameter size.

Wherever the pipe changes direction, place a hanger within twelve

(12) inches on one side and within twelve to nineteen (12 to 19)

inches of the bend on the other side as shown in Figure 35.

Figure 33: Pipe Hanger Details

Figure 34: Typical Pipe Support

Location—Change in Pipe Direction

Figure 35: Pipe Support at

Indoor Unit

Max. 12"

~ 12" – 19"

A

B

A + B ~ 12" – 19"

Loading ...

Loading ...

Loading ...