Loading ...

Loading ...

Loading ...

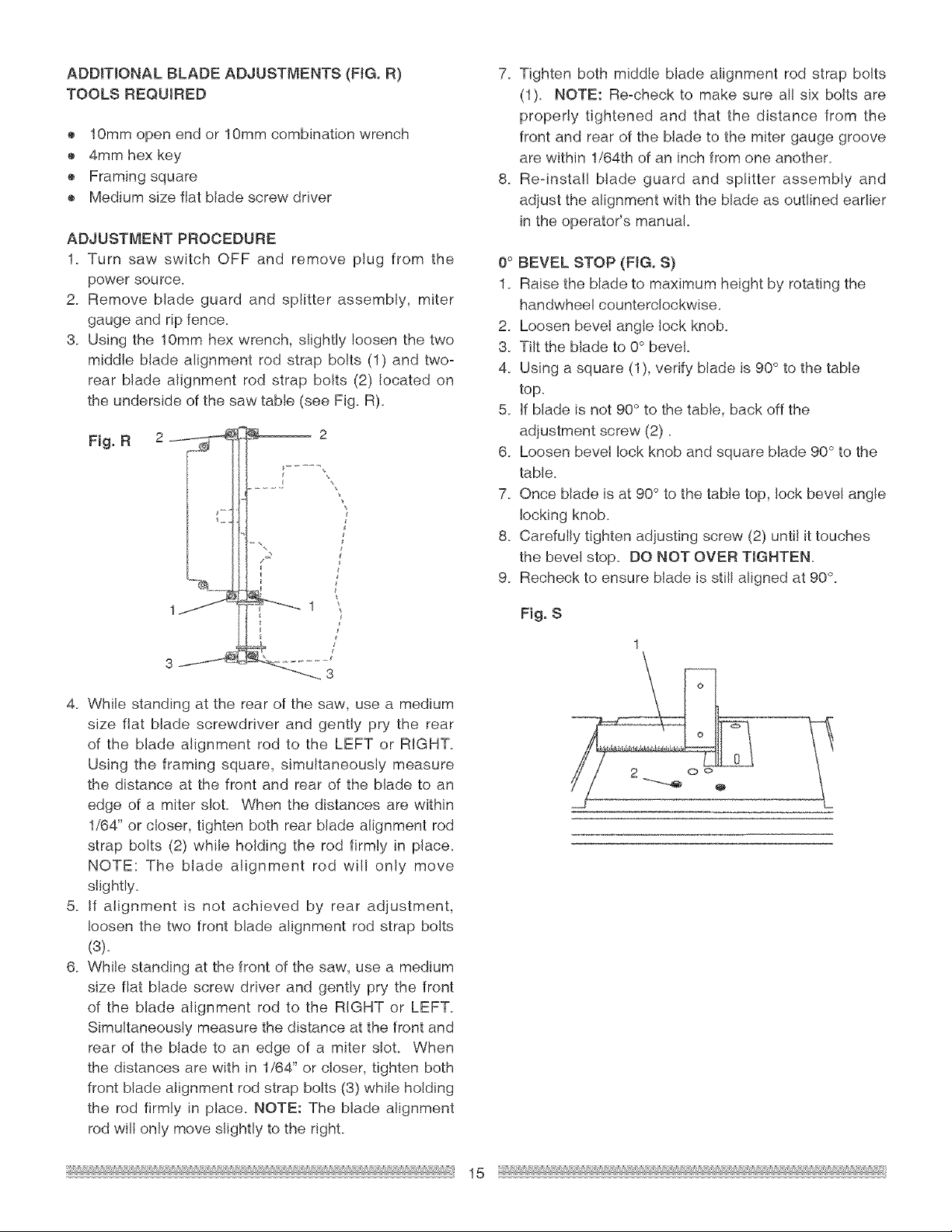

ADDiTiONALBLADEADJUSTMENTS(FIG.R)

TOOLSREQUIRED

o 10mmopenendor10ramcombinationwrench

® 4ramhexkey

o Framingsquare

o Mediumsizeflatbladescrewdriver

ADJUSTMENTPROCEDURE

1. Turn saw switch OFF and remove plug from the

power source.

2. Remove blade guard and splitter assembly, miter

gauge and rip fence.

3. Using the 10ram hex wrench, slightly loosen the two

middle blade alignment rod strap bolts (1) and two-

rear blade alignment rod strap bolts (2) located on

the underside of the saw table (see Fig. R).

4. While standing at the rear of the saw, use a medium

size flat blade screwdriver and gently pry the rear

of the blade alignment rod to the LEFT or RIGHT.

Using the framing square, simultaneously measure

the distance at the front and rear of the blade to an

edge of a miter slot. When the distances are within

1/64" or closer, tighten both rear blade alignment rod

strap bolts (2) while holding the rod firmly in place.

NOTE: The blade alignment rod will only move

slightly.

5. If alignment is not achieved by rear adjustment,

loosen the two front blade alignment rod strap bolts

(3).

6_ While standing at the front of the saw, use a medium

size flat blade screw driver and gently pry the front

of the blade alignment rod to the RIGHT or LEFT.

Simultaneously measure the distance at the front and

rear of the blade to an edge of a miter slot. When

the distances are with in 1/64" or closer, tighten both

front blade alignment rod strap bolts (3) while holding

the rod firmly in place. NOTE: The blade alignment

rod will only move slightly to the righL

7. Tighten both middle blade alignment rod strap bolts

(1). NOTE: Re-check to make sure all six bolts are

properly tightened and that the distance from the

front and rear of the blade to the miter gauge groove

are within 1/64th of an inch from one another.

8_ Re-install blade guard and splitter assembly and

adjust the alignment with the blade as outlined earlier

in the operator's manual.

0° BEVEL STOP (FIG. S)

1. Raise the blade to maximum height by rotating the

handwheel counterclockwise.

2. Loosen bevel angle lock knob.

3. Tilt the blade to 0° bevel.

4. Using a square (1), verify blade is 90 ° to the table

top.

5. If blade is not 90 ° to the table, back off the

adjustment screw (2)

6. Loosen bevel lock knob and square blade 90 ° to the

table.

7. Once blade is at 90° to the table top, lock bevel angle

locking knob.

8. Carefully tighten adjusting screw (2) until it touches

the beve! stop. DO NOT OVER TIGHTEN.

9_ Recheck to ensure blade is stilI aligned at 90%

Fig. S

15

Loading ...

Loading ...

Loading ...