Loading ...

Loading ...

Loading ...

43

W415-0748 / 12.12.08

A

B

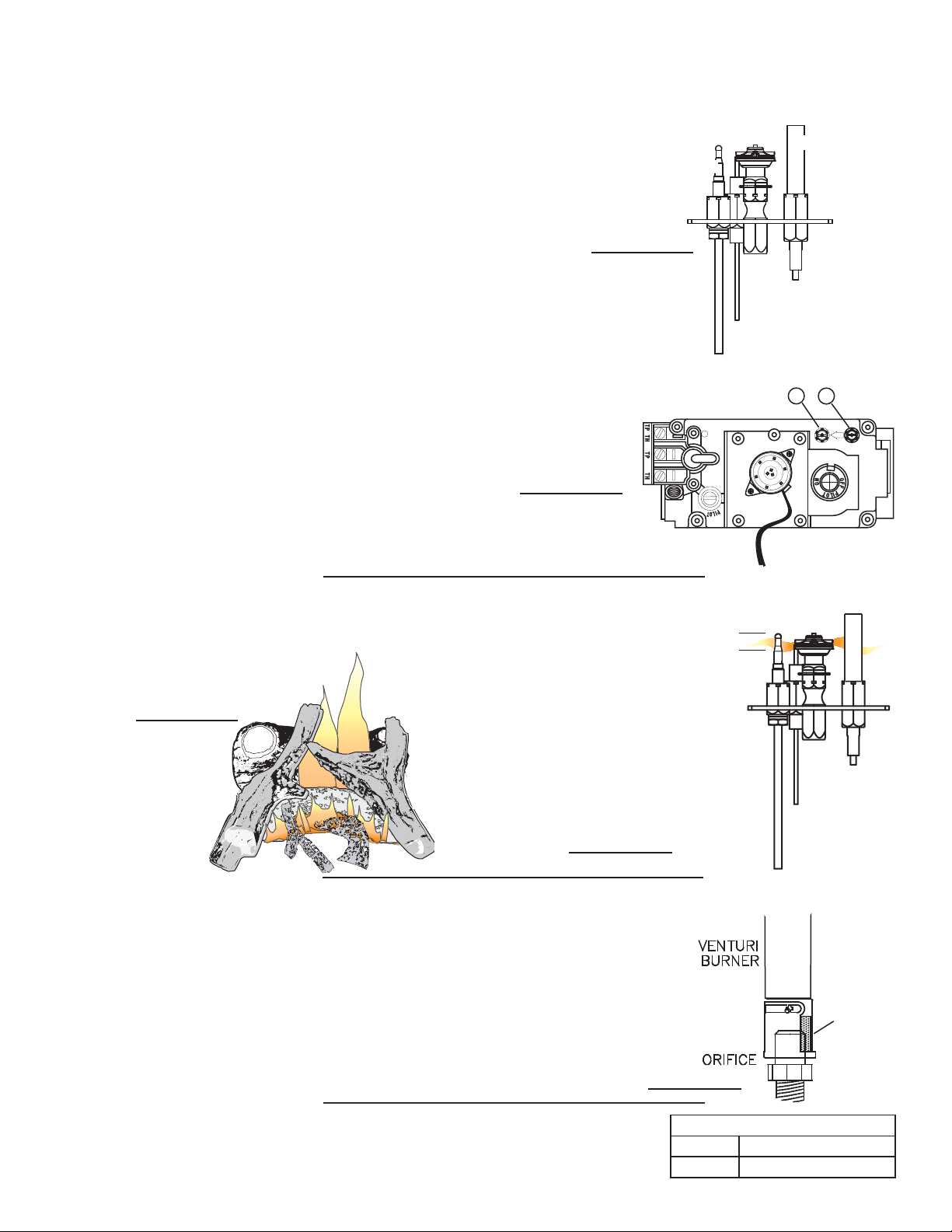

Adjust the pilot screw to provide properly sized flame. Turn in a clockwise

direction to reduce the gas flow.

Inlet pressure can be checked by turning screw (A)

counter-clockwise until loosened and then placing pressure gauge

tubing over the test point. Gauge should read 7” (minimum 4.5”)

water column for natural gas or 13” (11” minimum) water column

for propane. Check that main burner is operating on “HI”.

Outlet pressure can be checked the same as above using screw (B).

Gauge should read 3.5” water column for natural gas or 10” water column

for propane. Check that main burner is operating on “HI”.

AFTER TAKING PRESSURE READINGS, TIGHTEN SCREWS FIRMLY

TO SEAL. DO NOT OVER TORQUE. LEAK TEST.

FLAME MUST

ENVELOPE UPPER

3/8" TO 1/2" OF

THERMOCOUPLE &

THERMOPILE

PILOT

BURNER

39.2

THERMOCOUPLE

THERMOPILE

AIR SHUTTER OPENINGS

LP 1/2”

NG 1/16”

10.0 ADJUSTMENTS

10.1 PILOT BURNER ADJUSTMENT

10.2 FLAME CHARACTERISTICS

10.3 VENTURI ADJUSTMENT

FIGURE 10.1b

FIGURE 10.1a

FIGURE 10.2b

FIGURE 10.2a

FIGURE 10.3

It is important to periodically perform a visual check of the pilot and burner

flames. Compare them to the illustration below.

54.2

3/8” - 1/2”

This

f

ireplace model has an air shutter that has been

f

actory set open according to the

chart below:

Closing the air shutter will cause a more yellow flame, but can lead to carboning.

Opening the air shutter will cause a more blue flame, but can cause flame lifting

from the burner ports. The flame may not appear yellow immediately; allow 15

to 30 minutes for the final flame color to be established.

AIR SHUTTER ADJUSTMENT MUST ONLY BE DONE BY A QUALIFIED

INSTALLER!

AIR

SHUTTER

OPENING

49.1

Loading ...

Loading ...

Loading ...