Loading ...

Loading ...

Loading ...

adjustments

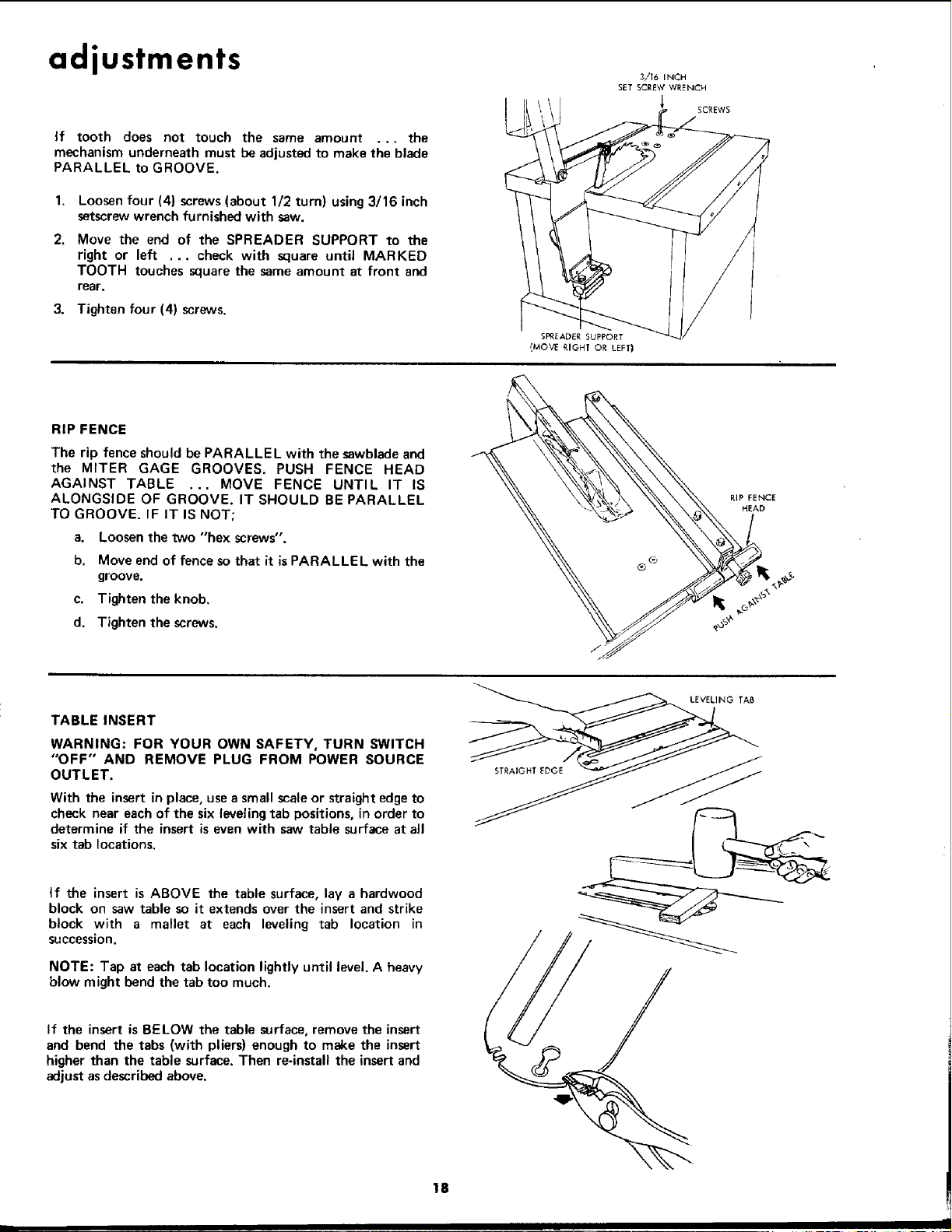

If tooth does not touch the same amount .. the

mechanism underneath must be adjusted to make the blade

PARALLEL to GROOVE.

1.

2.

Loosen four (4) screws (about 1/2 turn) using 3/16 inch

setscrewwrench furnished with saw,

Move the end of the SPREADER SUPPORT to the

right or left ... check with square until MARKED

TOOTH touches square the same amount at front and

rear.

3. Tighten four (4) screws,

SPREADER SUPPORT

(MOVE RIGHI OR LEFT)

3/16 iNCH

SET SCREW WRENCH

SCREWS

RIP FENCE

The rip fence should be PARALLEL with the sawblade and

the MITER GAGE GROOVES. PUSH FENCE HEAD

AGAINST TABLE ... MOVE FENCE UNTIL IT IS

ALONGSIDE OF GROOVE. IT SHOULD BE PARALLEL

TO GROOVE. IF IT IS NOT,

a. Loosen the two "hex screws".

b. Move end of fence so that it isPARALLEL with the

groove.

c. Tighten the knob.

d. Tighten the screws.

RiP FENCE

HEAD

TABLE INSERT

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET.

With the insert in place, use a small scaleor straight edge to

check near each of the six leveling tab positions, in order to

determine if the insert is even with saw table surface at all

six tab locations.

If the insert is ABOVE the table surface, lay a hardwood

block on saw table so it extends over the insert and strike

block with a mallet at each leveling tab location in

succession.

NOTE: Tap at each tab location lightly until level. A heavy

blow might bend the tab too much.

If the insert is BELOW the table surface, remove the insert

and bend the tabs (with pliers) enough to make the insert

higher than the table surface. Then re-install the insert and

adjust asdescribed above.

LEVELING TAB

18

STRAIGHT EDGE

L

Loading ...

Loading ...

Loading ...