Loading ...

Loading ...

Loading ...

lubrication

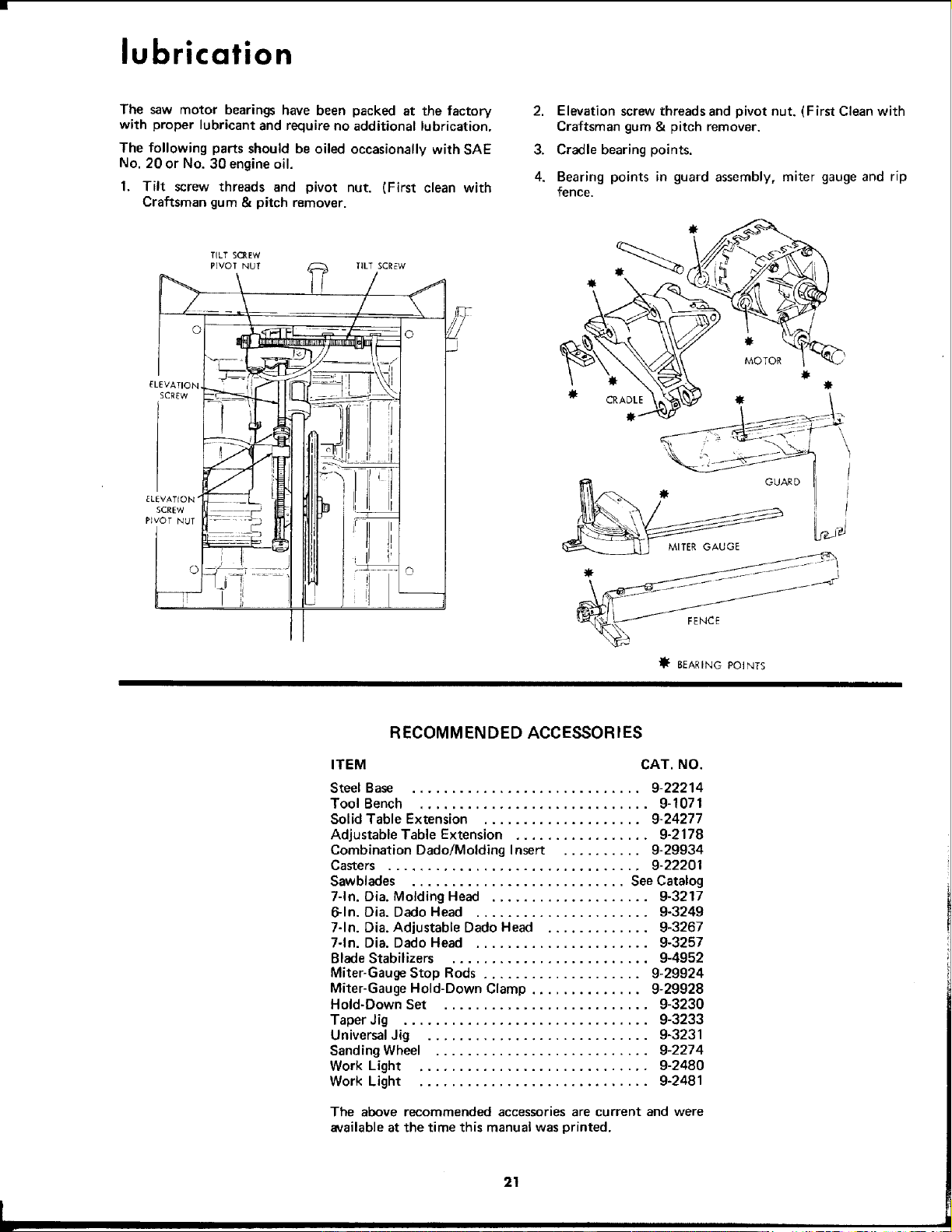

The saw motor bearings have been packed at the factory

with proper lubricant and require no additional lubrication.

The following parts should be oiled occasionallv with SAE

No. 20 or No. 30 engine oil.

1. Tilt screw threads and pivot nut. (First clean with

Craftsman gum & pitch remover.

TILT SCREW

PIVOT NUT _ TILT SCREW

[LEVATION ': _ i-" -

sc.ew -- -_ t_1 rillIP i_

_lVOTNUT...... _ J]];'J_II[ I_

II!lilIIII

I o _- _JlII1!III IP-_/_

.........t

J ], IlL J J.LL

l

2.

3.

4.

Elevation screw threads and pivot nut. (First Clean with

Craftsman gum & pitch remover.

Cradle bearing points.

Bearing points in guard assembly, miter gauge and rip

fence.

CRADLE

MOTOR

GUARD

MITER GAUGE

FENCE

"_ BEARING POINTS

RECOMMENDED ACCESSORIES

ITEM CAT. NO.

Steel Base ............................. 9-22214

Tool Bench ............................. 9-1071

Solid Table Extension .................... 9-24277

Adjustable Table Extension ................. 9-2178

Combination Dado/Molding Insert .......... 9-29934

Casters ................................ 9-22201

Sawblades ........................... See Catalog

7-In. Dia. Molding Head .................... 9-3217

6-In. Dia. Dado Head ...................... 9-3249

7-In. Dia. Adjustable Dado Head ............. 9-3267

7-In. Dia. Dedo Head ...................... 9-3257

Blade Stabilizers ......................... 9-4952

Miter-Gauge Stop Rods .................... 9-29924

Miter-Gauge Hold-Down Clamp .............. 9-29928

Hold-Down Set .......................... 9-3230

Taper Jig ............................... 9-3233

Universal Jig ............................ 9-3231

Sanding Wheel ........................... 9-2274

Work Light ............................. 9-2480

Work Light ............................. 9-2481

The above recommended accessories are current and were

available at the time this manual was printed.

21

Loading ...

Loading ...

Loading ...