Loading ...

Loading ...

Loading ...

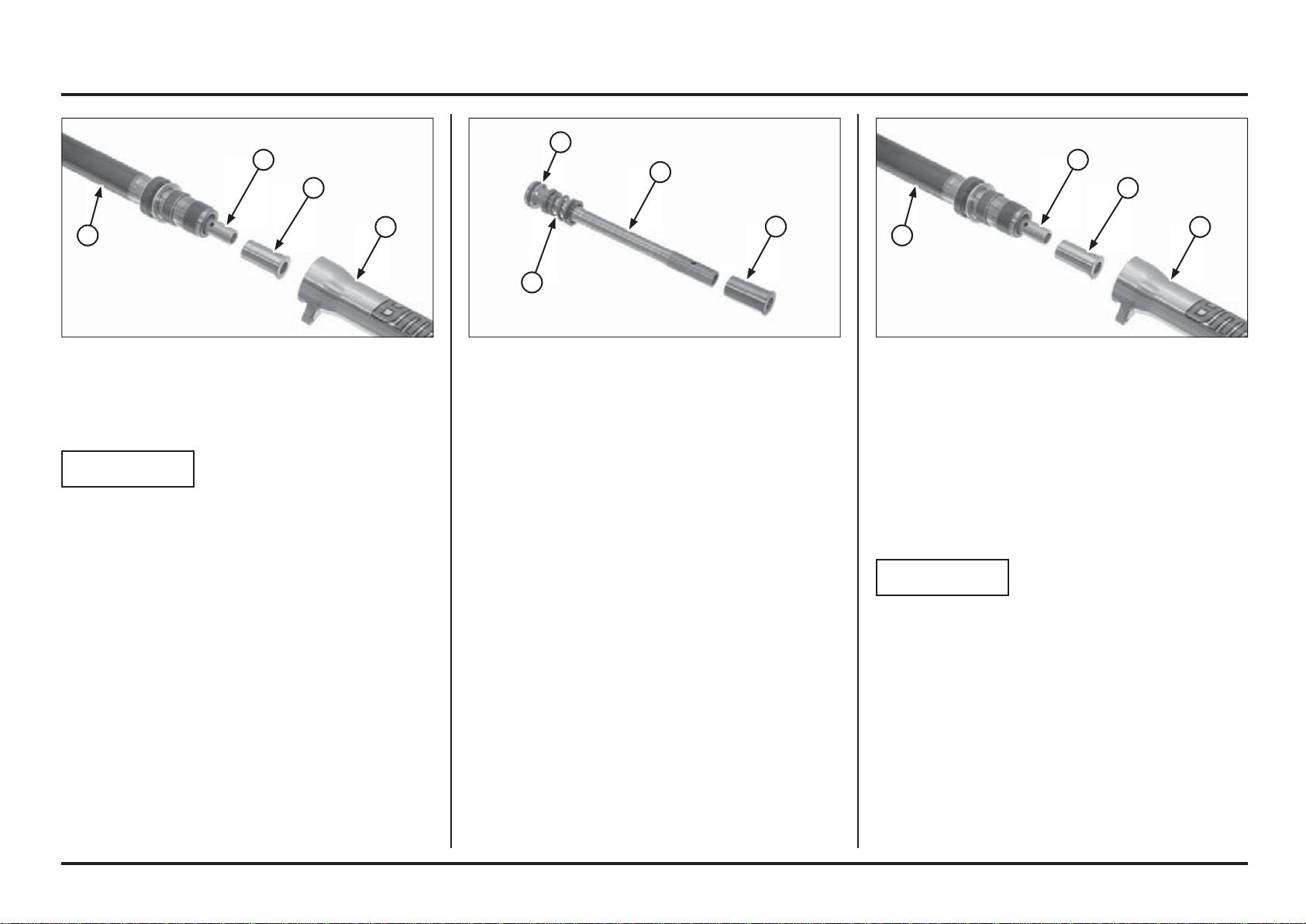

(1) CILINDER ASSY

(2) PISTON RING

(3) REBOUND SPRING

(4) TAPERED BUSHING

Left Fork Inspection

Check the following items (page 2-4):

– Inside fork slider for damage or deformation

– Fork tube runout

– Fork spring free length

– Fork tube for score marks, scratches and excessive

wear

– Bushing/back-up ring (page 5-5)

– Fork piston ring for wear or damage

– Tapared bushing for damage

– Rebound spring for fatigue or other damage

(1) FORK TUBE

(2) CILINDER ASSY

(3) TAPERED BUSHING

(4) FORK BOTTLE

Remove the tapared bushing from the cilinder assy.

NOTE

Be careful not to damage the tapared bushing.

Remove the cilinder assy from the fork tube.

Remove the following items using the same procedure as

the right fork disassembly (page 5-3):

– Oil seal

– Back-up ring

– Guide bushing

– Fork tube bushing

(1) FORK TUBE

(2) CILINDER ASSY

(3) TAPERED BUSHING

(4) FORK BOTTLE

Left Fork Assembly

Clean the parts thoroughly with non-flammable or high

flush point solvent before assembly.

Apply fork fluid to the piston ring.

Install the cilinder assy into the fork tube.

Install the tapered bushing on the end of the cilinder assy.

NOTE

The tapered bushing is easy to scratched or deformed.

Take care not to damage it when assembling it.

5-9

5-9

Frame servicing

1

2

2

3

3

4

4

1

1

2

3

4

Loading ...

Loading ...

Loading ...