Loading ...

Loading ...

Loading ...

Winding/Installing the Bobbin

Basic operations B-15

GETTING READY

B

e

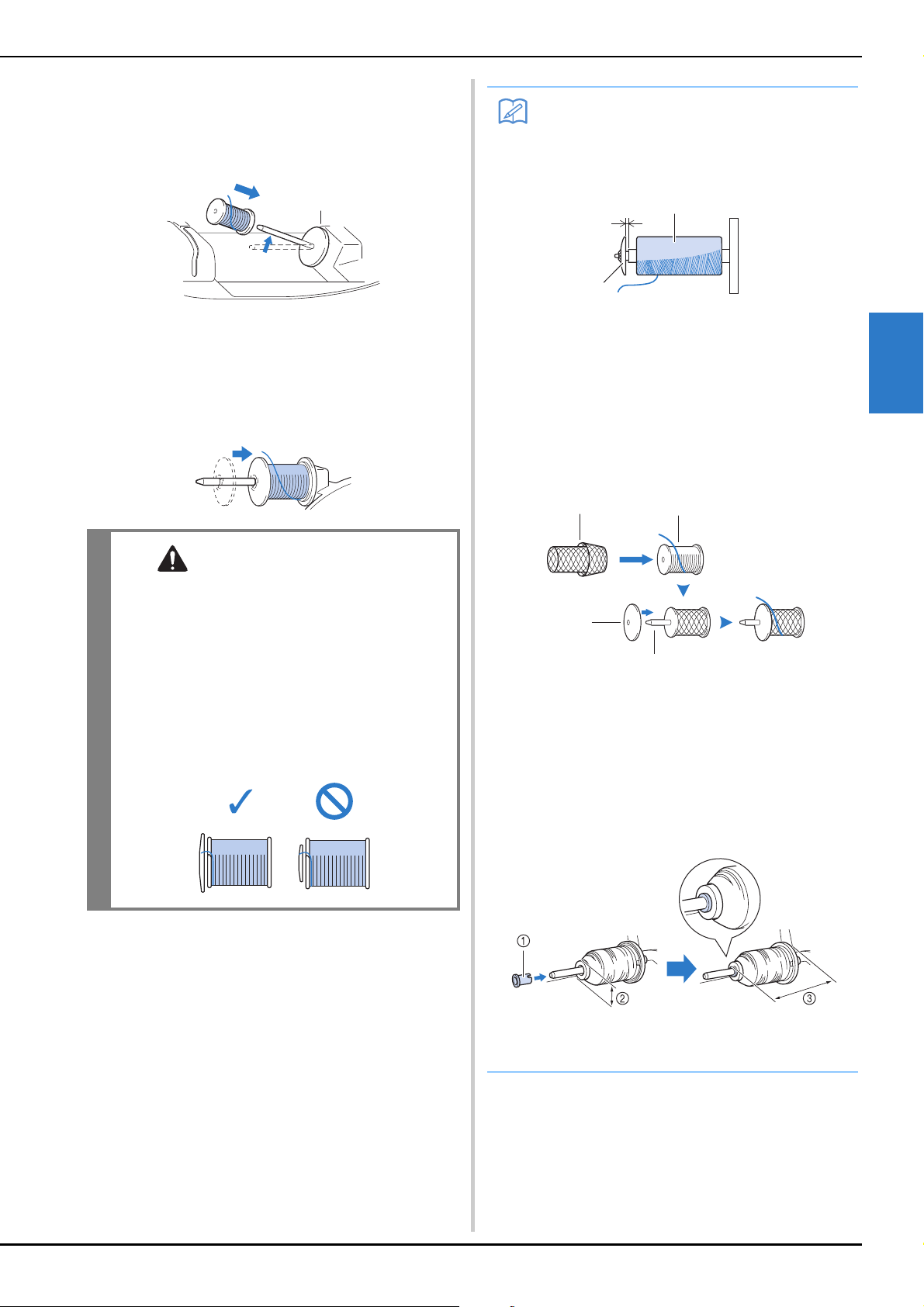

Place the spool of thread for the bobbin onto the spool

pin.

Slide the spool onto the pin so that the spool is

horizontal and the thread unwinds to the front at the

bottom.

• If the spool is not positioned so that the thread

unwinds correctly, the thread may become tangled

around the spool pin.

f

Slide the spool cap onto the spool pin.

Slide the spool cap as far as possible to the right, as

shown, with the rounded side on the left.

CAUTION

• If the spool or the spool cap is not installed

correctly, the thread may become tangled

around the spool pin, causing the needle to

break.

• Three spool cap sizes are available, allowing

you to choose a spool cap that best fits the size

of spool being used. If the spool cap is too

small for the spool being used, the thread may

catch on the slit in the spool or the machine

may be damaged.

Memo

• When sewing with fine, cross-wound thread, use

the small spool cap, and leave a small space

between the cap and the spool.

1 Spool cap (small)

2 Spool (cross-wound thread)

3 Space

• When using thread that winds off quickly, such as

metallic thread, place the spool net over the spool

before placing the spool of thread onto the spool

pin.

If the spool net is too long, fold it to fit the size of

the spool.

1 Spool net

2 Spool

3 Spool cap

4 Spool pin

• If a spool of thread whose core is 12 mm (1/2

inch) in diameter and 75 mm (3 inches) high is

inserted onto the spool pin, use the thread spool

insert (mini king thread spool).

1 Thread spool insert (mini king thread spool)

2 12 mm (1/2 inch)

3 75 mm (3 inches)

a

c

b

2

1

4

3

Loading ...

Loading ...

Loading ...