Documents: Go to download!

User Manual

- User Manual - (English, French, Portuguese, Spanish)

- Safety and Legal - (English)

- Quick Setup Guide - (English)

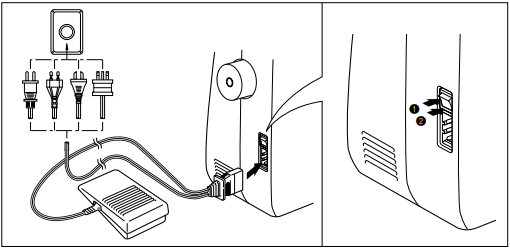

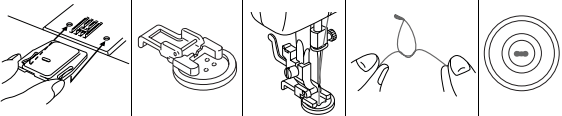

- Connecting Plugs and Main Power / Sewing Light Switch

- PRINCIPAL PARTS

- OPERATING YOUR SEWING MACHINE

- VARIOUS CONTROLS

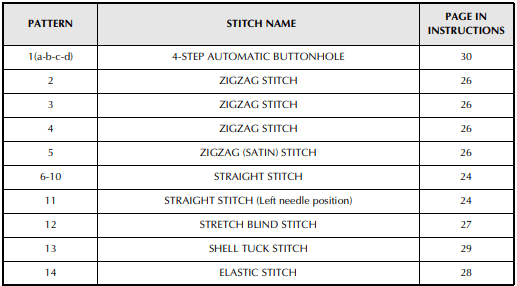

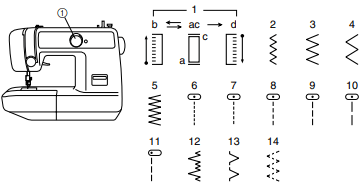

- PATTERNS AND STITCH NAMES

- THREADING THE MACHINE

- Cleaning

Table of contents

User manual Sewing Machine

Connecting Plugs and Main Power / Sewing Light Switch

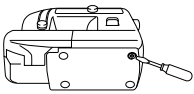

1. Connect the three-prong plug into the machine.

2. Connect the electrical supply plug into a wall outlet.

- When leaving the sewing machine unattended, the main switch of the machine must be switched off or the plug must be removed from the socket outlet.

Turn on or off the switch for the main power and sew-light.

Turn on

Turn on

Turn off

Turn off

- When servicing the sewing machine, or when removing covers or changing lamps, the machine or the electrical set must be disconnected from the supply by removing the plug from the socket outlet.

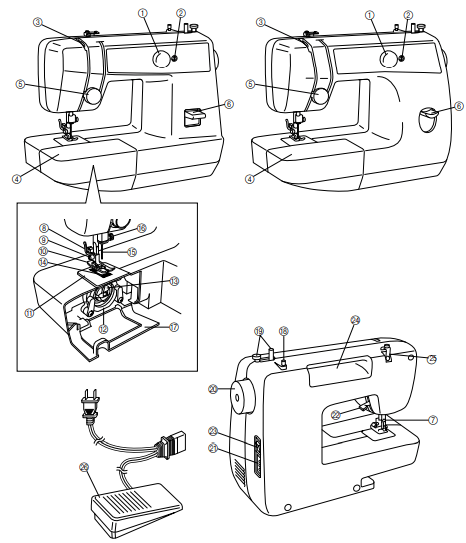

PRINCIPAL PARTS

ELEMENTOS PRINCIPALES

* The illustrations of the sewing machine on the following pages may differ slightly from your machine.

PRINCIPAL PARTS

- Pattern selection dial

- Buttonhole fine-adjusting screw

- Thread take-up lever

- Extension table with accessory storage

- Upper tension control dial

- Reverse sewing lever

- Thread cutter

- Presser foot holder assembly

- Presser foot screw

- Presser foot (Zigzag)

- Needle plate (Zigzag)

- Shuttle hook

- Bobbin case

- Feed dogs

- Needle

- Needle clamp screw

- Shuttle cover

- Spool pin

- Bobbin winder

- Balance wheel

- Foot controller jack

- Presser foot lever

- Main power/sewing light switch

- Built-in handle

- Thread guide/bobbin winding tension disc

- Foot controller

OPERATING YOUR SEWING MACHINE

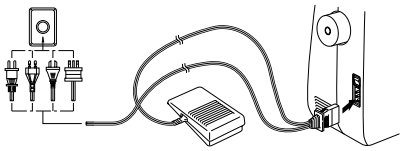

Connecting Plugs

1. Insert the foot controller plug, located between the foot controller and the power supply plug on the cord, into the jack on the machine.

2. Insert the power supply plug into an electrical outlet.

CAUTION:

1. When changing the light bulb or when the sewing machine is not in use, the power supply plug must be disconnected from the wall socket to avoid electrical hazards.

2. For U.S.A. only

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only one way. If the plug does not fit completely in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

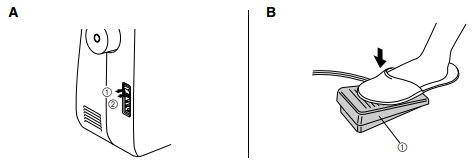

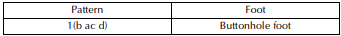

Main Power and Sewing Light Switches

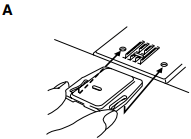

This switch turns the main power and sewing light on or off. (See fig. A.)

Turn on (toward the “I” mark)

Turn on (toward the “I” mark)

Turn off (toward the “O” mark)

Turn off (toward the “O” mark)

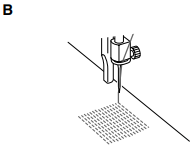

Foot Controller

When the foot controller is depressed lightly, the machine will run at a low speed. When the pressure on the foot controller is increased, the machine’s speed will increase. When pressure on the foot controller is released, the machine will stop. (See fig. B.)

NOTE:

1. Be sure that nothing is placed on the foot controller when the machine is not being used.

2. A new sewing machine or one that has not been in use for a long period of time should be oiled as described on page 43. After oiling, be sure to wipe off any excess oil.

Note (For U.S.A. only): This foot controller can be used for sewing machine model LS-2220/2720.

Foot controller: Model N

Foot controller: Model N

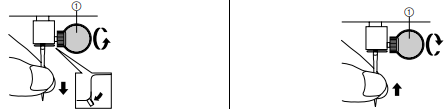

Inserting the Needle

Turn power switch to “O”.

1. Remove the power supply plug from the electrical outlet.

2. Raise the needle bar to its highest position.

3. Lower the presser foot.

4. If a needle is already installed, remove the needle by loosening the needle clamp with a coin and pulling the needle down.

5. With the flat side toward the back, insert the new needle as far as possible up against the needle stopper.

6. Tighten the needle clamp.

Coin

Coin

Checking the Needle

1. The sewing needle must always be straight and sharp for smooth sewing.

2. To check if the needle is bent, place the flat side of the needle down as shown in the illustration.

3. Replace the needle if it is bent or dull.

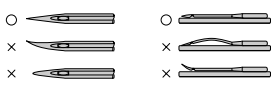

Changing the Presser Foot

It may be necessary to change the presser foot according to your sewing needs.

SNAP-ON TYPE

Turn power switch to “O”.

- Raise the needle to its highest position by turning the balance wheel toward you (counterclockwise), and raise the presser foot lever.

- Release the foot by raising the lever located at the back of the presser foot holder assembly.

- Place a different presser foot on the needle plate so that the bar on the presser foot is in line with the slot on the shank.

- Lower the presser foot lever and fix the presser foot onto the shank. If the presser foot is in the correct location, the bar should snap in.

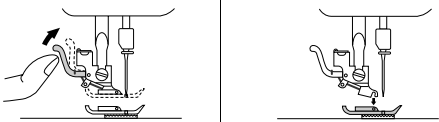

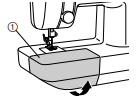

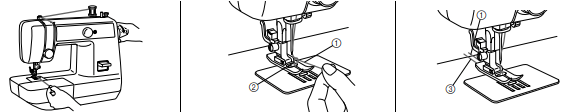

Converting to Free-Arm Style

Free-Arm sewing is convenient for sewing tubular and hard-toreach areas on garments. To change your machine to the free-arm style, lift up on the extension table and pull it out.

Lift the bottom of the extension table up toward you.

Lift the bottom of the extension table up toward you.

Pull the extension table out to remove it.

Pull the extension table out to remove it.

Extension table

Extension table

Steadying the Machine

When the sewing machine is placed on an uneven surface, turn the rubber cushion on the front right-hand side of the base plate to adjust its height until the sewing machine is stable.

VARIOUS CONTROLS

Pattern Selection Dial

To select a stitch, simply turn the pattern selection dial in either direction. Stitch widths and lengths are shown on the following page.

Pattern selection dial

Pattern selection dial

PATTERNS AND STITCH NAMES

Reverse Sewing Lever

To sew in reverse, press down the reverse sewing lever as far as possible and hold it in that position while lightly stepping on the foot controller. To sew forward, release the reverse sewing lever. Reverse sewing is used for locking and reinforcing seams.

THREADING THE MACHINE

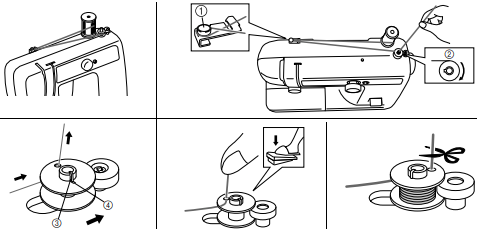

Winding the Bobbin

1. Place the spool of thread on the spool pin and pass the thread around the bobbin winding tension disc.

Bobbin winding tension disc

Bobbin winding tension disc

Bobbin winding

Bobbin winding

2. Pass the end of the thread through the hole in the bobbin from the inside.

3. Place the bobbin onto the bobbin winding shaft and slide the shaft to the right. Turn the bobbin clockwise, by hand, until the spring on the shaft slides into the slit on the bobbin.

Spring

Spring

Slit

Slit

4. While holding the end of the thread, gently press on the foot controller to wind the thread around the bobbin a few times, then stop the machine.

5. Trim the excess thread sticking out from the top of the bobbin and continue winding the thread onto the bobbin by pressing down on the foot controller.

NOTE: The machine stops automatically when the bobbin is full.

6. When the machine stops, cut the thread between bobbin and spool, push the shaft to the left and remove the full bobbin from the shaft.

CAUTION: Although the needle bar does not move when the bobbin winding shaft is slid toward the bobbin presser, the balance wheel will continue to turn. Therefore, do not touch the balance wheel while the bobbin is being wound.

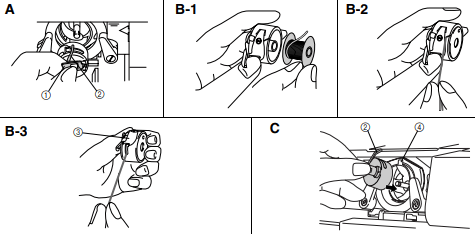

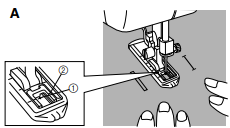

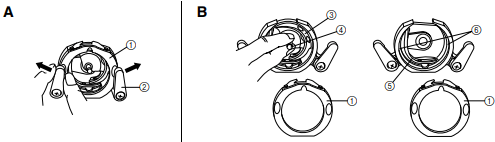

Lower (bobbin) Threading

Turn power switch to “O”.

- Raise the needle to its highest position by turning the balance wheel toward you (counterclockwise) and raise the presser foot lifter.

- Open the shuttle cover behind the extension table on the front of the machine and remove the bobbin case by pulling its latch toward you and pulling it out from the shuttle race (fig. A).

- Unwind about 10 cm (4") of thread from a full bobbin and insert the bobbin into the bobbin case. (See fig. B-1.) Pull the trailing thread into the slot, down and to the left, as shown in fig. B-2, until it enters the delivery eye under the tension spring (fig. B-3).

- Holding the bobbin case by the latch, fully insert the bobbin case into the shuttle race and release the latch. Make sure the bobbin case finger fits into the notch at the top of the race as shown in fig. C.

NOTE: If the bobbin case is not properly placed back into the machine, it will fall out from the shuttle immediately after starting to sew.

Bobbin case latch

Bobbin case latch

Bobbin case finger

Bobbin case finger

Tension spring

Tension spring

Notch

Notch

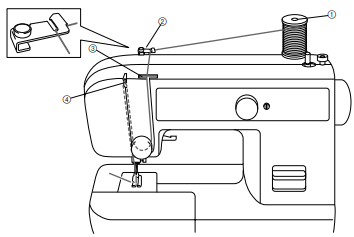

Upper (Needle) Threading

1. Raise the presser foot using the presser foot lifter and turn the balance wheel toward you (counterclockwise) to raise the thread take-up lever to its highest position.

2. Pull up the spool pin and place a spool of thread on this pin.

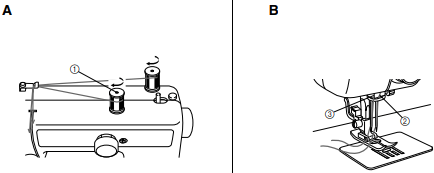

3. Pass the thread through both thread guides: the rear one first, then the front one. (fig. A)

Spool pin

Spool pin

Thread guide (rear)

Thread guide (rear)

Thread guide (front)

Thread guide (front)

Thread take-up lever

Thread take-up lever

4. Pull the thread down and around the upper tension control dial from the right to the left so the thread picks up the thread check spring. (See fig. B.) While holding the thread as shown in fig. C, pull it between the tension discs.

Upper tension control dial

Upper tension control dial

Thread check spring

Thread check spring

5. Guide the thread to the back of the thread take-up lever and around to the left (fig. D). Bring the thread through the slit by pulling it toward you and into the eyelet.

Thread take-up lever

Thread take-up lever

6. Bring the thread down and pass it behind the thread guide.

Thread guide

Thread guide

7. Thread the needle from front to back and pull out about 5 cm (2") of thread as shown in fig. E.

NOTE: If the thread is incorrectly fed, the thread may break, cause stitches to be skipped or cause the fabric to wrinkle.

Drawing Up Lower (bobbin) Thread

1. Raise the presser foot and the needle to their highest positions.

2. With your left hand, hold the end of the upper thread. With your right hand, turn the balance wheel toward you (counterclockwise) until the needle moves down and back up again to its highest position.

3. The upper thread should have caught the lower thread in a loop. Pull the upper thread toward you and the lower thread will come up from the bobbin in a large loop.

4. Pull out about 15 cm (6") of both threads and place them toward the back of the machine straight behind the presser foot. The upper thread should pass between the toes of the presser foot.

Upper thread

Upper thread

Lower thread loop

Lower thread loop

Lower thread

Lower thread

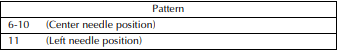

Twin-Needle Sewing

Your sewing machine is designed for twin-needle sewing which allows you to sew using two upper threads. You can use the same color or two different colors of thread for decorative stitches. Twin-needle sewing works well with these stitches: the Straight Stitch (6-10)-and the Zigzag Stitch (2). Be sure that the two upper threads used for threading the twin needle have the same weight. If the threads do not have the same weight, the stitching may not be consistent.

INSERTING THE TWIN NEEDLE

Insert the twin needle in the same way that a single needle is inserted. (Refer to page 6.) The flat side of the needle should face toward the back and the rounded side should face toward you.

SETTING THE EXTRA SPOOL PIN

Place the extra vertical spool pin in the hole found on the top right-hand side of the machine. Place the second spool of thread on this pin as shown in fig. A.

Extra spool pin

Extra spool pin

TWIN NEEDLE THREADING

Each needle should be threaded separately.

1. Threading the Right Needle Follow the same instructions for single needle threading. See page 15 for more details.

2. Threading the Left Needle Thread the left needle in the same way as the right needle was threaded, but do not pass the thread through the thread guide above the needle before passing it through the eye of the left needle as shown in fig. B.

Right needle thread passes through this guide.

Right needle thread passes through this guide.

Left needle thread passes in front of this guide.

Left needle thread passes in front of this guide.

Thread Tension

Thread tension will affect the quality of your stitches. It may need to be adjusted when you change fabric or thread type.

NOTE:

It is recommended that a test sample be made on a fabric scrap before sewing on your project.

The basic thread tension setting is “5”.

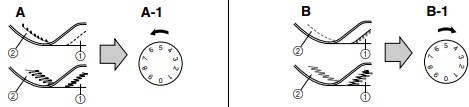

Possible problems and how to correct them.

A Upper tension is too tight.

Locks appear on the surface of the fabric.

A-1 Upper tension control dial

Decrease the tension by turning the dial to a lower number.

B Upper tension is too loose.

Locks appear on the reverse side of the fabric.

B-1 Upper tension control dial

Increase the tension by turning the dial to a higher number.

Reverse

Reverse

Surface

Surface

NOTE:

The bobbin thread tension has already been adjusted at the factory for general use. For most sewing applications, no adjustment is needed.

When sewing with thin thread on thin fabrics, the thread tension may not be adjusted adequately with the upper tension control dial. Therefore, the thread tension must be adjusted according to the procedure described below.

C Bobbin tension is too loose.

Locks appear on the surface of the fabric.

Decrease the thread tension by turning the dial to a lower number. If the result is still not satisfactory, then adjust the bobbin thread tension as explained in C-1

C-1 Bobbin

Increase the tension in the bobbin by turning the screw with a small screwdriver in a clockwise direction. However, do not turn the screw more than one full turn.

Remember to return the screw to its original setting before starting your next project.

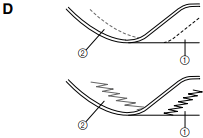

D Correct tension

Correct tension is important since too much or too little tension will weaken your seams or cause puckers in your fabric.

Reverse

Reverse

Surface

Surface

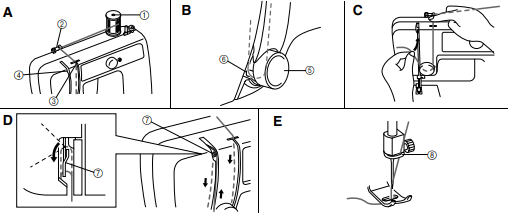

Straight Stitching

The Straight Stitch (6-10 or 11) is used for top stitching and sewing lightweight fabrics.

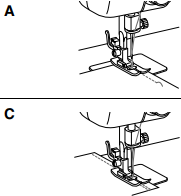

Starting Sewing (fig. A)

- Set the pattern selection dial to the appropriate Straight Stitch (6-10 or 11) with the desired length.

- Raise the needle to its highest position and lift the presser foot lifter.

- Pull up the bobbin thread by turning the balance wheel toward you (counterclockwise) and place both the upper and lower threads toward the back behind the presser foot.

- Place the fabric under the presser foot and position the needle 1 cm (3/8") from the edge of the fabric.

- Lower the presser foot.

- To backtack, press the reverse sewing lever down as far as possible and lightly touch the foot controller. Sew 5 to 10 stitches in the reverse direction.

- Release the reverse sewing lever and start sewing in the forward direction by applying pressure to the foot controller.

NOTE: The backtack or reverse sewing is used for locking the end of seams and reinforcing stitches.

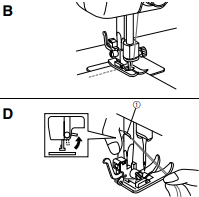

Changing Sewing Direction (fig. B)

- Stop the machine at the point where you wish to change directions with the needle still in the fabric. If the needle ends in the up position, turn the balance wheel toward you (counterclockwise) until the needle enters the fabric.

- Raise the presser foot and turn the fabric to line up its new direction using the needle as a pivot point.

- Lower the presser foot and start sewing in the new direction.

NOTE: For twin needle sewing, raise the needle when changing the sewing direction.

Finishing Sewing (fig. C)

Reverse stitching is used to lock the threads at the end of the seam or wherever reinforcement is needed.

- Stitch to the end of the seam and stop.

- Press the reverse sewing lever down and lightly touch the foot controller to stitch backwards for 1 cm (3/8") from the end of the fabric over the top of the existing stitch.

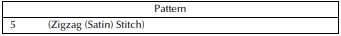

Removing the Fabric From the Machine (fig. D)

1. Stop the machine.

2. Turn the balance wheel toward you (counterclockwise) to bring the needle and thread take-up lever to their highest position.

3. Lift the presser foot and pull the fabric out gently to the left side.

4. Cut both threads using the thread cutter located on the back of the presser foot bar.

Thread cutter

Thread cutter

5. To prepare the machine for the next seam, pull about 10 cm (4") of both threads and place them toward the back of the machine. The upper thread should pass between the toes of the presser foot.

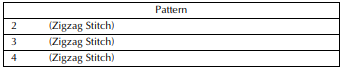

Zigzag Stitching

ZIGZAG STITCH

Set the pattern selection dial to the appropriate Zigzag Stitch (2, 3 or 4) with the desired width.

It is recommended to sew using the Straight Stitch at the beginning and end of the Zigzag Stitches.

ZIGZAG (SATIN) STITCH

The Satin Stitch can be used for making decorative stitches. Set the pattern selection dial to the Zigzag (Satin) Stitch (5).

Blind Hem Stitching

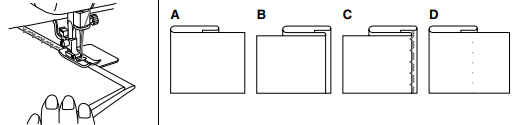

The Stretch Blind Stitch is used to finish the edge of projects made with stretch fabrics without the stitch showing.

1. Set the pattern selection dial to 12.

2. Both the threads should be the same color as the fabric.

3. Fold back the fabric to the desired location of the hem as shown in fig. A. Then, fold the edge of the fabric as in fig. B. Leave a 6 mm (1/4") overlap at the edge.

4. Sew on the fold as in fig. C.

5. When the fabric is unfolded you will have a Stretch Blind Stitch hem as shown in fig. D.

Elastic Stitching

The Elastic Stitch can be used in 3 ways: mending, sewing elastic or joining fabric. Each is explained below. Set the pattern selection dial to 14.

MENDING

1. Place the reinforcement fabric under the tear to be mended.

2. Following the line of the tear, sew using the Elastic Stitch as illustrated in fig. A.

SEWING ELASTIC

1. Place the elastic on the fabric.

2. As you sew, stretch the elastic both in the front and behind the presser foot as shown in fig. B.

JOINING FABRIC

The Elastic Stitch can be used to join two pieces of fabric together and is very effective when sewing knitted fabrics. When nylon thread is used, the stitch will not be visible.

1. Place the edge of the two pieces of fabric together and center them under the presser foot.

2. Sew them together using the Elastic Stitch taking care to keep the two fabric edges close together as shown in fig. C.

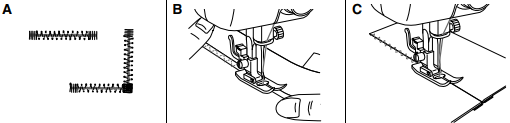

Shell Tuck Stitching

The Shell Tuck Stitch can be used to sew a picot (lace-like) edge on a lightweight fabric.

1. Set the pattern selection dial to 13.

2. Use a tighter thread tension than normal.

3. At a slow speed, sew the fabric on the bias, placing it under the presser foot so that the straight stitches are sewn on the seamline and the zigzag stitches are sewn slightly over the folded edge.

Making a Buttonhole

NOTE:

1. It is recommended to practice making a buttonhole on a scrap piece of fabric before attempting it on the actual garment.

2. When making buttonholes on soft fabrics, place stabilizer material on the underside of the fabric.

Buttonhole-making is a simple process that provides reliable results.

MAKING A BUTTONHOLE

1. Using tailor’s chalk, mark the position and length of the buttonhole on the fabric.

2. Attach the buttonhole foot and push the outside frame back until the sliding insert is in the front.

3. The front bar tack will be sewn first. Place the fabric under the presser foot so that the middle of the front of the tailor’s chalk line is directly in the center of the presser foot and aligned with the two red lines on the insert as shown below.

Front of chalk mark

Front of chalk mark

Red lines

Red lines

MAKING A BUTTONHOLE

Step a (Front end of buttonhole)

1. Set the pattern selection dial to a.

2. Lower the presser foot and sew 5 to 6 stitches.

3. Stop the machine when the needle is at the left side of the stitches and raise the needle from the fabric.

Step b (Left side)

1. Turn the pattern selection dial to b.

2. Sew the predetermined length of the tailor’s chalk line.

3. Stop the machine when the needle is at the left side of the stitch and raise the needle.

Step c (Back end of buttonhole)

1. Turn the pattern selection dial to c (same as a).

2. Lower the presser foot and sew 5 to 6 stitches.

3. Stop the machine when the needle is at the right side of the stitch and raise the needle from the fabric.

Step d (Right side)

1. Set the pattern selection dial to d.

2. Sew the right side until the needle reaches the stitches formed in step a.

SECURING THE STITCHING AND CUTTING THE BUTTONHOLE

1. To secure the stitching, turn the material 90 degrees counterclockwise, set the pattern selection dial to the Straight Stitch (6-10) with the desired length and sew to the edge of the front bar tack.

2. Remove the fabric from the machine. It is recommended that pins be placed across both ends of the buttonhole as protection against cutting the stitches.

3. Cut an opening in the middle of the buttonhole with a seam ripper tool. Be careful not to cut through any stitches.

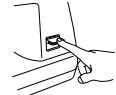

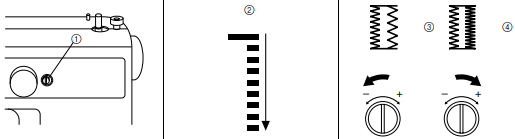

Buttonhole Fine Adjustment

If the stitching on the two sides of the buttonhole do not appear uniform, the following adjustments can be made.

1. After sewing the left side of the buttonhole, stitch the right side and observe the feeding.

2. If the right side is too coarse or fine compared to the left side, adjust the buttonhole fine-adjusting screw as described below.

If the right side is too coarse, turn the buttonhole fine-adjusting screw with the enclosed large screwdriver in the – direction.

If the right side is too fine, turn the buttonhole fine-adjusting screw with the enclosed large screwdriver in the + direction.

This adjustment allows both sides of the buttonhole to appear uniform.

Buttonhole fine-adjusting screw

Buttonhole fine-adjusting screw

Right row

Right row

Right row

Right row

Too fine

Too fine

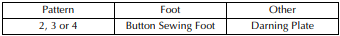

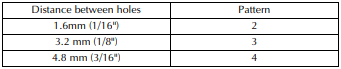

Button Sewing

1. Measure the distance between the buttonholes and set the pattern selection dial to the Zigzag Stitch (2, 3 or 4) with the desired width.

2. Attach the button sewing foot.

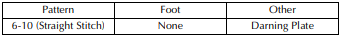

3. Place the darning plate on the needle plate as shown in fig. A.

4. Place a button between the foot and the fabric, turn the balance wheel and make sure that the needle enters the holes without hitting the button. If it hits, see step 1.

5. At a slow speed, sew approximately 10 stitches.

6. Remove the material from the machine. Cut the upper and lower threads leaving 15cm (6") lengthes. Use a hand-sewing needle to draw the upper thread to the back of the material. Tie the two threads together to secure.

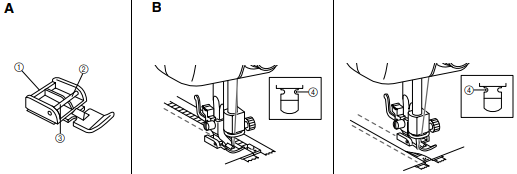

Zipper Insertion

The zipper foot is used to sew on various types of zippers and can easily be positioned to the right or left side of the needle.

When sewing the right side of the zipper, attach the shank to the left pin of the zipper foot. When sewing the left side of the zipper, attach the shank to the right pin of the zipper foot. See fig. A.

1. Set the pattern selection dial to the Straight Stitch (6-10) with the desired length.

2. Lower the presser foot lever and attach either the left or right pin of the zipper foot onto the shank.

3. Fold the edge of the fabric 2 cm (3/4") back and place the zipper under the folded portion.

4. Lower the needle into the notch located on the side of the zipper foot.

5. Sew from the bottom of the zipper toward the top on both sides. The needle should be positioned on the zipper side of the foot for best results. See fig. B. Sew through the fabric close to the edge of the zipper guiding the zipper foot along the zipper teeth.

6. To sew the opposite side of the zipper, release the foot by raising the lever located at the back of the presser foot holder assembly, install the zipper foot on the other side of the zipper and continue sewing using the other side notch.

Zipper foot

Zipper foot

Right pin for sewing the left side of the zipper

Right pin for sewing the left side of the zipper

Left pin for sewing the right side of the zipper

Left pin for sewing the right side of the zipper

ower the needle into the notch

ower the needle into the notch

Gathering

1. Set the pattern selection dial to the Straight Stitch (6-10) with the desired length.

2. Loosen the tension of the upper thread (to about 2) so that the lower thread lies on the underside of the fabric.

3. Sew a single row or evenly-spaced multiple rows of Straight Stitches.

4. Pull the lower thread(s) to gather the fabric.

Darning

1. Place the darning plate on the needle plate as shown in fig. A.

2. Set the pattern selection dial to the Straight Stitch (6-10) with the desired length.

3. Place the portion to be darned under the presser foot together with a fabric underlay for reinforcement.

4. Either remove both the presser foot and presser foot holder assembly or use an embroidering presser foot (sold separately).

5. Begin sewing alternating between gently drawing the work away from you and pulling it toward you. With the darning plate on the machine, the feed dogs will not move the fabric. You control the fabric movement with your hands.

6. Repeat this motion until the portion to be darned is filled with parallel lines of stitching. See fig. B.

Monogramming and Embroidering

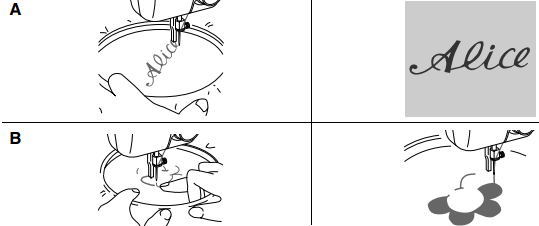

MONOGRAMMING (fig. A)

1. Sew moving the hoop slowly along the lettering at a constant speed.

2. To secure the stitching, set the pattern selection dial to the Straight Stitch (6-10) with the desired length and sew a few stitches at the end of the last letter.

EMBROIDERING (fig. B)

1. Stitch the outline of the design by moving the embroidery hoop.

2. Fill in the design alternating from the outline of the design to the inside and from the inside to the outline until the design is completely filled in. Keep the stitching close together.

NOTE: A long stitch is made by moving the embroidery hoop rapidly and a short stitch is made by moving it slowly.

3. To secure the stitching, set the pattern selection dial to the Straight Stitch (6-10) with the desired length and sew a few stitches at the end of the design.

CAUTION: Keep fingers away from moving parts, especially needles.

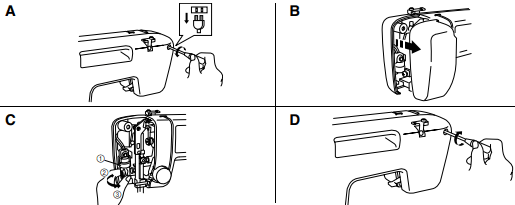

Changing the Bulb

1. Remove the power supply plug from the electrical outlet.

2. Loosen the face plate screw as shown in fig. A.

3. Remove the face plate from the machine as illustrated in fig. B.

4. Replace the sewing light bulb. See fig. C.

Bulb

Bulb

Loosen

Loosen

Tighten

Tighten

5. Reattach the face plate and fasten the screw as shown in fig. D.

Oiling

- Remove the power supply plug from the outlet.

- Put 2 to 3 drops of oil at each of the points indicated in fig. A.

- After oiling, run the machine at a fast speed without thread installed for a short time.

- Be sure to wipe any excess oil off the machine.

NOTE:

The machine should be oiled once a week if it is used more than one hour a day. If the machine is used more often, oil every day.

Sewing machine oil is available from your local sewing machine dealer or service center.

Do not apply too much oil as it may get on your thread and fabric.

Cleaning

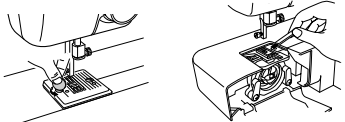

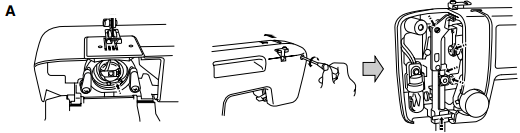

Removing the Shuttle Hook

1. Remove the needle.

2. Remove the extension table and open the shuttle cover on the front of the free arm.

3. Take out the bobbin case by opening its latch and pulling it out from the shuttle race.

4. Slide the latch levers out from the retaining ring to remove the retaining ring. See fig. A.

5. Remove the hook by grasping its center post of the hook and pulling it out as shown in fig. B.

NOTE: When the needle is lowered, the shuttle hook cannot be removed.

Cleaning the Shuttle Race

1. Remove any accumulated lint and thread with a brush from the retaining ring, hook, driver and race body.

2. A cloth dampened with machine oil should be used to wipe the shuttle race clean of lint.

3. Clean the lint from the shuttle hook in the same manner as described in step 2.

4. Reassemble the hook with the notch at the top and push the latch levers back to their positions to hold the retaining ring in place.

Retaining ring

Retaining ring

Latch lever

Latch lever

Hook

Hook

Hook center post

Hook center post

Driver

Driver

Race body

Race body

Cleaning the Feed Dogs

1. Remove the presser foot holder and the needle.

2. Remove the needle plate using a coin or screwdriver to take out the screws.

3. Clean the lint from the upper part of the feed dogs and shuttle race body with a brush.

Performance Checklist

Whenever sewing difficulties are encountered, review the section in this instruction manual that details the operation you are performing to make sure you are correctly using the machine. If the problem continues, the following checklist may help you to improve the operation.

If you still have difficulties, contact your nearest service center.

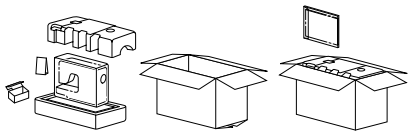

Repacking the Machine

Keep the carton and packing materials for future use. It may become necessary to reship the sewing machine. Improper packing or improper packing material could result in damage during shipping. Instructions for repacking the machine are illustrated below.

IMPORTANT This packing material is designed to prevent damage in transit. Save this packing material in the event it is needed to transport this sewing machine.

See other models: QL-1050N PE-770 DCP-8150DN PJ-562 MFC-9125CN