Loading ...

Loading ...

Loading ...

15

VENTING THE DRYER (continued)

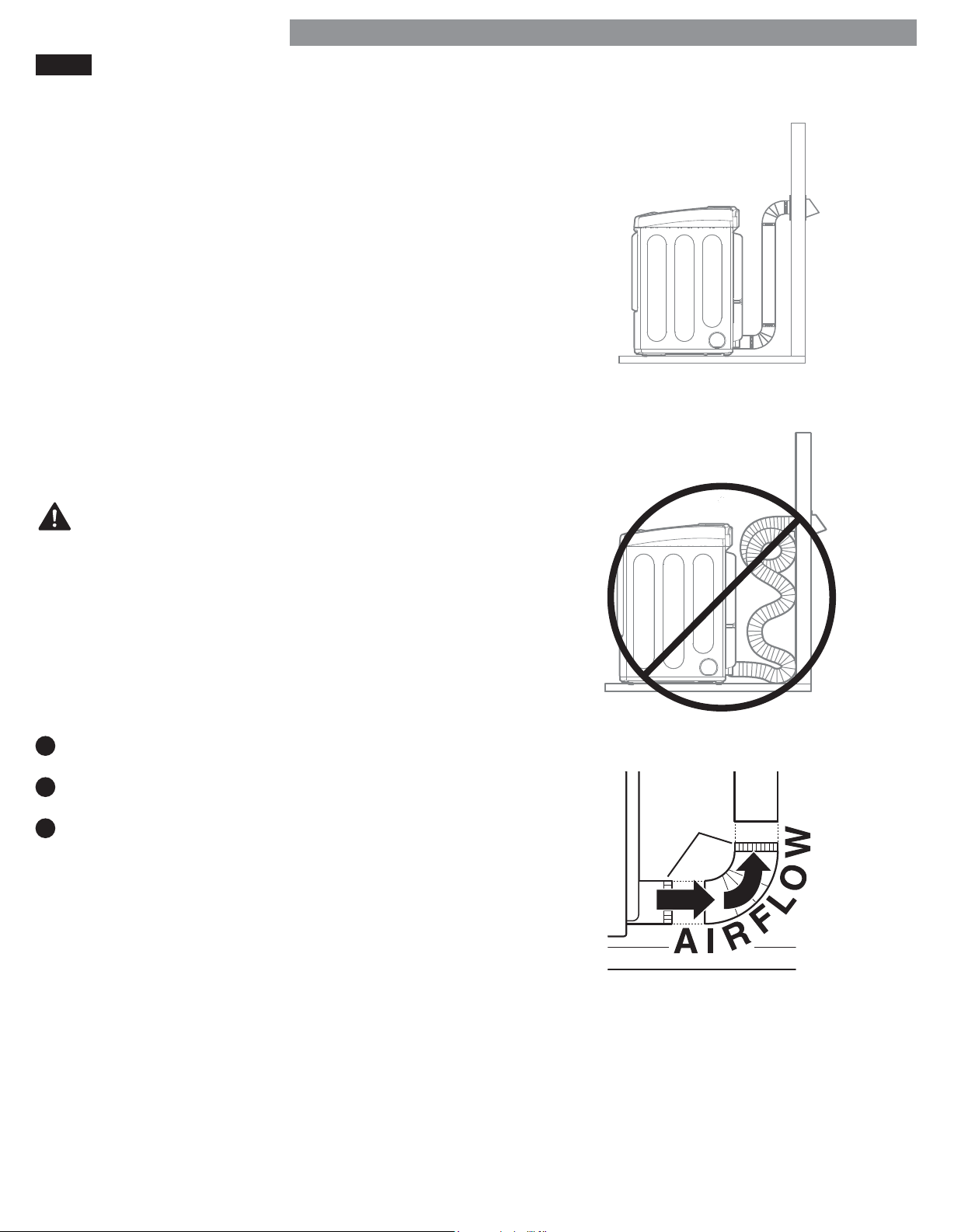

Routing and Connecting Ductwork

Follow the guidelines below to maximize dryer

performance and reduce lint buildup and condensation in

the ductwork.

NOTE: Transition duct and fi ttings are NOT included and

must be purchased separately.

• Use 4 inch (102mm) diameter rigid or semi-rigid

metal duct.

• The exhaust duct run should be as short as possible.

• Use as few elbow joints as possible.

• The male end of each section of exhaust duct must point

away from the dryer.

• Use duct tape on all joints. Never use screws.

• Insulate ducts that runs through unheated areas in order

to reduce condensation and lint buildup on

duct surfaces.

• The total length of semi-rigid metal transition duct

should not exceed 8 ft. (2.4 m).

IMPORTANT: Failure to exhaust the dryer, per the

guidelines included within these instructions, may

result in unsatisfactory dryer performance. All venting

and ductwork beyond the exterior of the dryer is the

responsibility of the consumer. Product failure, as a result

of improper venting, is not covered by the manufacturer’s

warranty.

Connecting the Dryer Vent

1

Verify all ducts and elbows are clean and free from

any blockages.

2

Measure duct length. DO NOT exceed the maximum

length listed in the Duct Length Chart.

3

Connect dryer exhaust to existing duct.

• Only use duct tape or clamps.

• DO NOT use screws to secure ductwork.

• Use rigid or semi-rigid metal ducts.

• DO NOT use plastic or thin metal foil tubing

for ductwork.

• The male end of each elbow must always point in the

direction of the airfl ow.

NOTE: Be careful when moving the dryer into its

fi nal location. Do NOT crush the duct. Make sure the

connections do not come loose.

WARNING: Failure to follow these

guidelines will result in poor performance and product

failure, and may result in fi re or death.

Male

Ends

Correct Venting

Incorrect Venting

INSTALLATION INSTRUCTIONS

Loading ...

Loading ...

Loading ...