Loading ...

Loading ...

Loading ...

28

A

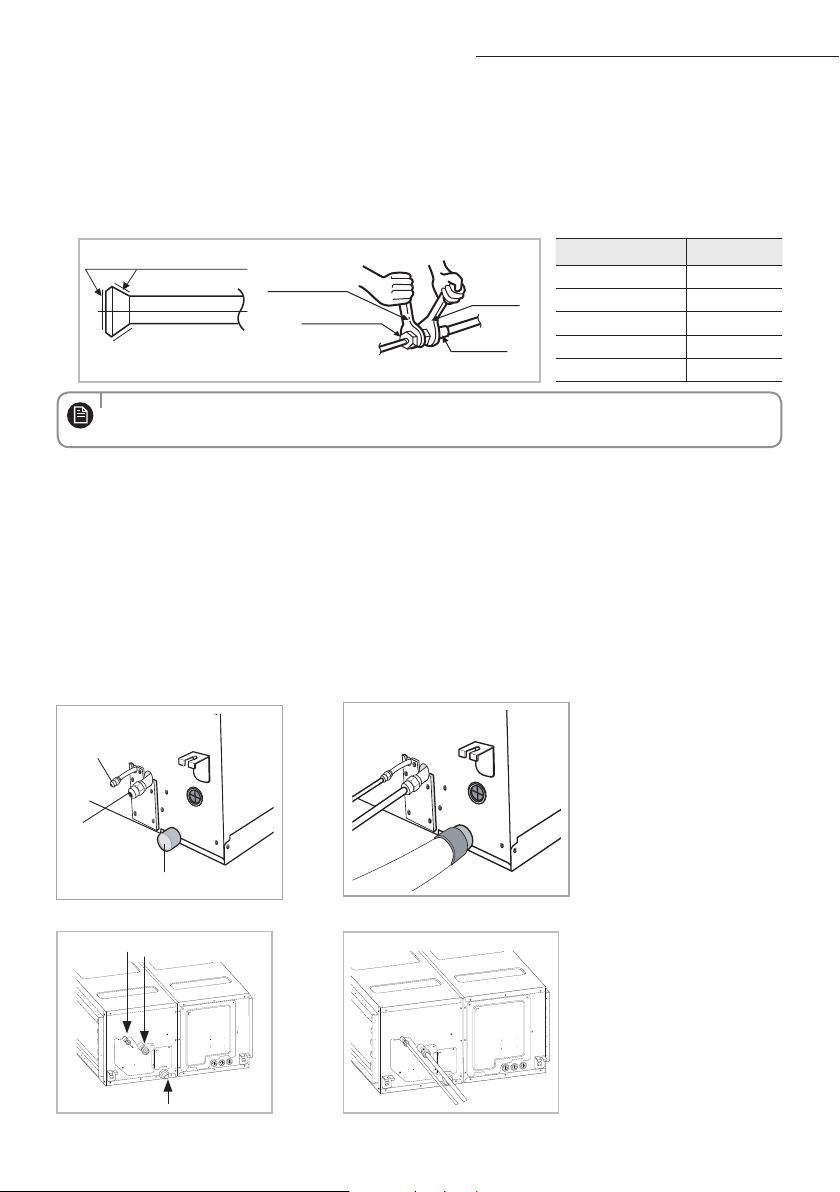

• Ifthepipesmustbeshortenedrefertopage29.

Refrigerant oil

Spanner

Union

Torque wrench

Flare nut

Outer Diameter (D) Torque (N•m)

ø6.35 mm 14~18

ø9.52 mm 34~42

ø12.70 mm 49~61

ø15.88 mm 68~82

ø19.05 mm 100~120

Connecting the refrigerant pipe

There are two refrigerant pipes of dierent diameters :

◆

A smaller one for the liquid refrigerant

◆

A larger one for the gas refrigerant

◆

The inside of copper pipe must be clean & has no dust

1. Remove the pinch pipe on the pipes and connect the assembly pipes to each pipe, tightening the nuts, rst manually

and then with a torque wrench, a spanner applying the following torque.

2. Must use insulator which is thick enough to cover the refrigerant tube to protect the condensate water on the outside

of pipe falling onto the oor and the eciency of the unit will be better.

3. Cut o any excess foam insulation.

4. Be sure that there must be no crack or wave on the bended area.

5. It would be necessary to double the insulation thickness(10mm or more) to prevent condensation even on the

insulator when if the installed area is warm and humid.

6. Do not use joints or extensions for the pipes that connect the indoor and outdoor unit. The only permitted connections

are those for which the units are designed.

G_4

Drain hose connection port

G_1

Liquid refrigerant port

Gas refrigerant port

Gas refrigerant port

Liquid

refrigerant port

Drain hose connection port

The designs and shape are subject to change according to the model.

NS

HHXEG

AC

JNHFKH

NOTE

Loading ...

Loading ...

Loading ...