Documents: Go to download!

User Manual

- User Manual - (English)

- Quick Reference guide - (English)

- Warning Label - (English)

- Service & Warranty Booklet - (English)

- Installation Guide (Cavity Sizes) - (English)

- Installation Guide - (English)

- INSTALLATION INSTRUCTIONS

- CONTROL PANEL

- DETERGENT AND SOFTENER DISPENSER

- CARING FOR YOUR WASHER

- CARING FOR YOUR WASHER

- BEFORE YOU CALL FOR SERVICE

- FAULT CODES

- TROUBLESHOOTING

Table of contents

User manual Washing Machine

INSTALLATION INSTRUCTIONS

Accessories

Check if you received the following accessories with your Fisher & Paykel washer. You will find them inside the drum or attached to the packaging.

● 2 x Inlet hose(s)

● 1 x Inlet valve cap

● 1 x Drain hose guide

● 1 x Installation guide and User guide

● 1 x Spanner

● 1 x Installation leaflet (attached to the top of the washer)

Unpacking

To ensure the best performance from your new washer follow the instructions below.

Removing the packaging

- Remove the outer packaging (including the expanded polystyrene packer and plastic wrapping). All packaging must be removed prior to use. Ensure these materials are kept out of reach of children. Note: a small amount of water may be seen inside the packaging and inside the washer. This is the result of factory testing and is normal.

- Tilt the machine backwards and ‘walk’ it off the base one foot at a time. Not doing so may cause damage to your floor and washer.

- Remove all packaging and accessories from inside the drum.

Removing transit safety bolts

The clothes washer is fitted with transit safety bolts at the rear to avoid possible damage to the interior during transportation.

IMPORTANT!

The transit bolts MUST be removed prior to operation of the machine. Failure to remove these will result in damage to the machine.

Note: the transit bolts MUST be removed in order to use the power cord.

To remove the bolts

- Use a spanner or socket to unscrew and remove all 4 transit bolts at the back of the washer (A).

- Pull the black rubber grommets to remove the bolt, grommet and white plastic spacers from the machine (B). Retain these for future use.

-362150.png)

3. Detach the drain hose from the plastic clasp, and remove the clasps on the side of the transit braces.

-161275.png)

4. Remove the 10 transit brace screws from the left and right sides, and near the centre of the top brace (refer to C).

5. Remove the braces (refer to D). Keep the braces and screws for future use.

-822089.png)

6. Pull out the two transit rods located below the two lower transit bolt holes and retain for future use (refer to E).

-976634.png)

7. Remove the yellow safety clip from the power cord.

8. Cover the transit bolt holes with the plastic plugs (provided). Push to clip into place (refer to F).

-533579.png)

Product dimensions

-470791.png)

-740019.png)

Note: the exact height of your washer is dependent on how far the feet are extended from the base of the machine. The space where you install your washer needs to be at least 40mm wider and 20mm deeper than its dimensions.

- Electrical supply: 220 – 240V, 50Hz sinusoidal, minimum 10A.

- Inlet water static pressure: Max. 1MPa (150psi), Min. 30kPa (4.5psi).

- Inlet water flow rate at tap: Min. 6 litres/min.

Location

IMPORTANT!

Install the machine on a solid and level floor surface ensuring it has at least 20mm clearance on each side. The washer must not be installed on any soft or textured floor coverings (eg carpet, rugs).

Note: This machine must not be installed and operated on a plinth.

Levelling the washer

IMPORTANT

Level the washing machine to ensure good spin performance, and to minimise noise, vibrations and wear and tear on the washer.

- Before positioning the washer in its final position, check that it is level, front to back and side to side.

- Adjust the washer into its final position (we suggest a minimum clearance of 20mm each side).

- Use a spirit level to check that the washer is correctly level. If needed, pull the washer out. Loosen the lock nut using the spanner provided and wind the feet up or down to correctly level the machine.

- Using the spanner provided, tighten the lock nuts against the base of the washer to lock the feet in position.

-313486.png)

Connecting to the water supply

Inlet hoses

IMPORTANT!

- Use new hose sets provided with the washer to connect the washer to the water mains.

- Old hose sets should not be re-used.

- We recommend the inlet hoses are changed every 5 years.

- WARNING: Failure to do so may result in a flood and damage to property.

- Connect the straight ends of the inlet hoses to the taps.

- Connect the elbow ends to the corresponding machine inlet valves. The hot valve is coloured orange to make this easier.

- Tighten the inlet hose ends by hand until the hose seal just makes contact with the tap sealing face. Continue to tighten a further half-turn. Make sure there are no kinks in the hoses.

- Turn the taps on and check for leaks. Check for leaks again after 24 hours.

-103119.png)

IMPORTANT!

The hot water temperature should not exceed 65°C and the cold water temperature not exceed 35°C. Temperatures above these may cause the washer to fault or cause damage to the machine.

If you have an uncontrolled water heating source (eg a wet back or solar heating system) you should fit a Hot ‘N’ Safe Valve. This will ensure the hot water temperature remains within safe limits.

Hot ‘N’ Safe Valves available are:

RMC TVA 50HF

RMC TVA 75HFS

Adjustable between 35°C – 55°C

RMC TVA 50HP

For instantaneous gas hot water supply

Water supply requirements:

- Inlet water pressure: Maximum 1MPa (150psi), Minimum 30kPa (4.5psi)

- Inlet water flow rate: Minimum 6 litres/minute

Cold supply only:

If you only have a cold water supply, the inlet valve cap (blanking cap) that came with your washer must be connected to the hot inlet valve. The cap prevents water leaking out of the hot valve. This appliance incorporates backflow protection complying with IEC61770. No further backflow protection is required for connection to the water supply.

Note: Your washer has an internal heater to heat water. If you do not connect a hot water inlet hose, your washer will automatically recognise there is no hot water supply and its internal heater will heat the cold water to the selected cycle temperature.

Draining

Placing the drain hose in a standpipe or tub

- To guide the drain hose over the tub or standpipe, the hose guide must be fitted to the drain hose. The height of the standpipe or tub should be between 600 – 1000mm.

- Secure the hose guide so it cannot be dislodged from the standpipe or tub.

-878837.png)

IMPORTANT!

- If the drain hose is placed on the ground or if the standpipe or tub is less than 600mm high, the washing machine will continuously drain while being filled (siphon).

- Regularly check that your standpipe or tub is free from lint or other obstructions, which may affect how your machine works or may cause flooding.

Attaching drain hose to spigot

- Guide the drain hose through the hose guide.

- Secure the hose guide to the back wall of cupboard using a screw. The height of the drain hose should be between 600 – 1000mm from ground level.

- Attach the drain hose to the spigot and secure using a hose clamp to ensure the blanking insert is cleared from the spigot.

- Check for leaks.

-776311.png)

- The drain hose should be checked from time to time and replaced if any damage (eg wear, cuts, bulges, kinks, leaks, etc) is found. Do not bend the drain hose sharply, as this may cause it to split.

- In multi-storey apartments or any upper floor, the machine should be installed on a floor equipped with a drain.

- Draining must comply with local by-laws.

Electrical connection

- This appliance must be connected to a 220V – 240V, 50Hz, sinusoidal, minimum 10A electrical supply.

- Release the power cord (transit bolts must be removed).

- Remove and discard the plastic pin cover and plug into a wall socket.

- Connect the appliance to an earthed outlet protected by a fuse of suitable capacity.

- Check the power cord for damage and make sure it is not squashed or twisted when installing the washer.

- Always remove the power cord from a socket by the plug, not by the cord.

IMPORTANT!

- If you are using an extension cord or a portable electrical outlet device (eg multi-socket outlet box), ensure that it is positioned so that it does not come into contact with water or moisture. FAILURE TO DO SO MAY RESULT IN DEATH OR ELECTRICAL SHOCK.

- Do not touch or operate the machine with wet hands or with bare feet.

- A damaged power cord must be replaced by a Fisher & Paykel trained and supported service technician or similarly qualified person in order to avoid a hazard. Do not use the appliance until it has been repaired to avoid a risk of electric shock.

- Do not operate this machine if it has been damaged during transport. Contact your Fisher & Paykel dealer or Fisher & Paykel trained and supported service technician.

Completing the installation

Installation test cycle

IMPORTANT!

Do this before you wash any items in your washer. This is to check that your washer is installed correctly and that it is functioning properly prior to use. We recommend to do an initial wash with a half dose of detergent.

- Turn your washer on by pressing the ‘POWER’ button.

- Select the ‘Quick’ or ‘Super Quick’ cycle. Ensure the drum is empty and the door closed.

- Touch the

-703643.png) button. The machine will start to fill.

button. The machine will start to fill.- Observe the machine for any problems (eg leaking from the hoses, excess noise or vibrations).

- The washer will beep and display any faults on the screen if there are any problems. Refer to the ‘Before you call for Service’ section at the back of this book.

- Continue to observe until you see water in the bottom of the drum.

- Touch

-703643.png) to pause the cycle, then press ‘POWER’ to turn the machine off.

to pause the cycle, then press ‘POWER’ to turn the machine off. - Press ‘POWER’ again, select the ‘Spin’ cycle and touch

-703643.png) .

.- Check that the drain hose is firmly secured to the standpipe or tub or spigot.

- Observe that the machine pumps out the water and spins.

IMPORTANT!

If there are any problems, you must address these before proceeding with normal use. The washer will automatically turn off at the end of the cycle if there are no problems.

CONTROL PANEL

-104251.png)

| 1 | POWER | Press to turn the washer ON/OFF. |

| 2 | Keylock | Touch to disable all buttons on the display panel, except ‘POWER' button. This prevents accidental button presses. |

| 3 | SmartTouch™ Control Dial | Rotate to select your desired wash cycle. |

| 4 | Digital display screen | Shows the following: • ‘Time to go' — the remaining time in the cycle that is currently running. • Delayed start time of wash cycle. • Notifications if an error is detected or a warning is necessary. |

| 5 | Progress lights | Indicate the current status of the wash cycle. • All lights are illuminated at the start of the wash cycle. • The light of the current status flashes, and then turns off once completed. |

| 6 | Less/More | Touch to increase or decrease the delay start time. |

| 7 | Wash Temp | Touch to increase or decrease water temperature. |

| 8 | Spin Speed | Touch to increase or decrease spin speed. |

| 9 | Soil Level | Touch to adjust the wash setting to suit the amount of soil in your load. |

| 10 | Wash Boost | Touch before wash cycle starts to select ‘Pre Wash' or ‘Rinse+'. |

| 11 | Options | Touch to access wash cycle options and washer settings. |

| 12 | START/PAUSE | Touch to start or pause the selected wash cycle. |

| Add a Garment | Touch to interrupt the wash cycle at any time to add or remove a garment. |

Time to Go

Time to go’ shows approximately the time remaining of the cycle you are currently running. This allows the user to get a glance of when washing will be done.

The overall cycle time can vary depending on several factors, such as water flow rate, water pressure, whether hot water is used from the tap or water is heated by the internal heater, load size, cycle and option selections. Other issues can also increase the cycle time, eg out of balance, oversudsing.

Add a Garment

The ‘Add a Garment’ option enables you to add or remove items during the wash stage of the cycle, under certain conditions.

- Once the ‘Add a Garment’ button is touched, the

-703643.png) button will flash and a notification will be shown on the display screen. Wait until you hear the door unlock.

button will flash and a notification will be shown on the display screen. Wait until you hear the door unlock. - Open the door and add or remove items. Close the door and touch

-703643.png) to restart the cycle.

to restart the cycle. - The ‘Add a Garment’ button will only operate during the wash part of the cycle and when the temperature selected is lower than 60°C. ‘Add a Garment’ can still be used if the water level is above the bottom of the door, as your washer will drain the water to a lower level so the door can be opened.

Keylock

This option enables you to deactivate the buttons on the display panel, except for the ‘POWER’ and ‘Keylock’ buttons. This prevents accidental button presses.

To turn Keylock mode ON or OFF when the washer is powered on:

- Touch and hold

-811133.png) button for 3 seconds. You will hear a beeping sound and

button for 3 seconds. You will hear a beeping sound and -811133.png) button illuminates to indicate ‘Keylock’ is active.

button illuminates to indicate ‘Keylock’ is active.

If Keylock mode is activated and the machine is powered off:

- To turn your washer on, press ‘POWER’ button, then touch and hold the

-811133.png) button for 3 seconds to deactivate ‘Keylock’. Select your wash cycle, options and then

button for 3 seconds to deactivate ‘Keylock’. Select your wash cycle, options and then -703643.png) to start the cycle.

to start the cycle. - To turn the washer off at anytime when ‘Keylock’ is activated simply press the ‘POWER’ button.

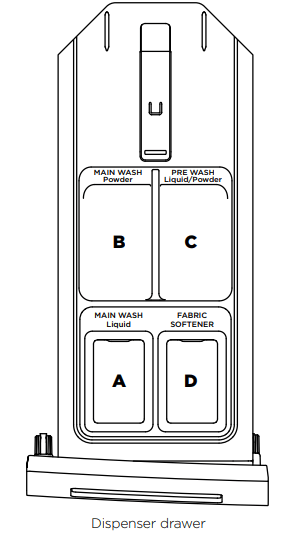

DETERGENT AND SOFTENER DISPENSER

The washer has two main wash compartments for liquid and powdered detergents, a fabric softener compartment, and a pre wash compartment for liquid or powdered detergent.

Detergent compartments

MAIN WASH Liquid (A)

For liquid detergent that mixes with water flushed into the compartment as the machine is filled.

MAIN WASH Powder (B)

For powdered detergent that mixes with water flushed into the compartment as the machine is filled.

PRE WASH Liquid/Powder (C)

Dispenses liquid/powdered detergent used for ‘Pre Wash’ option. The detergent is flushed out of the compartment at the start of the cycle.

FABRIC SOFTENER (D)

For fabric softener flushed automatically during the rinse part of the cycle.

IMPORTANT!

Make sure that the dispenser drawer is completely closed before starting the cycle. Do not open it again until the cycle is complete and the machine has stopped spinning.

CARING FOR YOUR WASHER

When you have finished using your washer

- Unplug the machine from the power socket.

- Wipe around the door and in the rubber gasket to remove any remaining water and foreign matter.

- Turn off the taps to prevent the chance of flooding should a hose burst.

Cleaning your washer

Before you start cleaning your washer, ensure that it is disconnected from the power (ie unplug the machine from the power socket).

Cleaning the control panel and outer surfaces of the washer

Use a soft damp cloth to wipe all surfaces, then wipe dry. Avoid using chemical or scouring cleaners, as these will damage the paint and plastic surfaces of your washer.

Cleaning the dispenser drawer

It is recommended that you clean the dispenser drawer regularly, especially if you use fabric softener.

-403063.png)

- To remove the drawer from the machine, pull it open, push down on the tab (A) behind the rear compartments and pull it out from the machine.

- To disassemble the drawer, first remove the compartment inserts for ‘MAIN WASH Liquid’ and ‘FABRIC SOFTENER’ (B).

- Turn the drawer upside down. Locate the tab labelled ‘REMOVE’ (C). Press down on it and towards the drawer front while pulling the front of the drawer away from the tab.

- These three parts can now be hand-washed in hot tap water and dried with a soft cloth. Reassemble and place back in the machine.

Note: The drawers are not dishwasher safe. Ensure the dispenser drawers are reassembled correctly to the machine. Any mis-assembly or damage to the parts could result in malfunction of the product.

CARING FOR YOUR WASHER

Cleaning the inside of your washer

It is important that you regularly clean the inside of your washer using the ‘Drum Clean’ cycle. After 100 cycles the -186075.png) icon will flash every time you turn your washer on to remind you to do this. If your washer starts to smell this is a sign that you should complete a ‘Drum Clean’ cycle. We recommend that you do not have any items in the washer when you run this cycle.

icon will flash every time you turn your washer on to remind you to do this. If your washer starts to smell this is a sign that you should complete a ‘Drum Clean’ cycle. We recommend that you do not have any items in the washer when you run this cycle.

To clean the inside of your washer:

- We recommend using a drum cleaning product specifically designed for front loading washing machines. (Follow the manufacturer’s instructions.)

- Press ‘POWER’ to turn your washer on and select the ‘Drum Clean’ cycle.

- Touch

-703643.png) to start the cycle.

to start the cycle.

Cleaning the drum and the door

- Use a soft damp cloth to wipe the door, cleaning any water marks or residue off it.

- Wipe the rubber seal around the door. Remove any items or lint accumulating in the bottom of the seal catchment and wipe out any water accumulated here. If this is not cleaned out, unpleasant odours will develop.

- If the drum has any residual dirt or lint stuck to it, remove this and wipe the drum clean.

- Do not leave any metal objects in the drum as these may rust and cause staining.

Cleaning the hoses

Each inlet hose has a filter in it, preventing any solid contaminants in the water from entering your washing machine. Occasionally you should disconnect the water inlet hoses where they connect to the taps, check these for any build up of dirt and wash the filters out.

Nappy sanitisers/bleach

Nappy sanitisers and bleach are very corrosive to metal surfaces. DO NOT tip the contents of a nappy bucket into your machine. Rinse and wring items out thoroughly before placing them in the machine.

IMPORTANT!

- Leave the door of your washer open when it is not in use to allow the washer to dry out, otherwise it will develop unpleasant odours. Ensure that children and pets are kept away from the washer when the door is left open so they cannot be accidentally trapped inside.

- Do not attempt to remove any part of the machine aside from the detergent dispenser, water hoses, and the pump filter. No other parts are designed to be removed from the machine for cleaning.

Cleaning the pump filter

The pump has a filter to trap foreign objects that enter the washer along with clothing. The pump filter can be accessed from the front of the washer. This should be cleaned out approximately once a month.

To clean the filter:

- Turn the power off and unplug the machine.

- Use a coin to open the filter cover. Place the edge of the coin into the slot and tilt upwards whilst levering the cover open.

-842520.png)

- Unhook the pump outlet hose and pull it out (about 150mm). Remove the plug and allow any water (approximately 250ml) to drain into a shallow dish.

- After the draining process is complete, replace the plug into the hose and refit the hose back into the housing.

- Remove the filter by turning anti-clockwise (A). Clean and rinse under a tap. Check the pump filter cavity for any further obstruction.

-656428.png)

- Replace the filter by turning clockwise until the turning handle stops in the vertical position, and cannot be turned further (A).

- Close the filter cover.

-186381.png)

Detergent advice

- If unpleasant odours are noticeable from your washer, it is possible that not enough detergent is being used for the soil level of your loads. Run a ‘Drum Clean’ cycle and either buy better quality detergent or use a higher dose. If you are using an ‘Eco’ detergent, alternate this with a mainstream one.

- Add the detergent BEFORE starting the cycle, close the dispenser and do not open it while the cycle is running.

- If you find foam leaking from your washer, check if you are using a low sudsing or front loader detergent when using ‘Manual Dose’. Check the quantity you are using against the manufacturer’s recommended dosage.

BEFORE YOU CALL FOR SERVICE

User warnings

Your washer is capable of diagnosing a number of its own problems. In most cases, your washer will sound a continuous series of beeps and display a code when it has a problem that you can correct yourself. All control panel lights will turn off and the code will be displayed to inform you what the problem is. To stop the beeps, press any button on the control panel. Do not try to continue washing once you stop the noise. You must address the problem the washer is alerting you to.

Check this chart before you call for service.

| USER WARNINGS AND DESCRIPTIONS | WHAT TO DO |

Keylock is activated | Touch and hold the ‘Keylock' button for 3 seconds. |

Pump filter is blocked | Clean the pump filter (refer to page 29). |

Water is not getting to the machine | Check the taps have been turned on. If there is no hot water connection the machine will heat the water itself, but there must be a cold water connection to the cold valve. Check the hose connections. If the cold water supply is connected to the hot valve and there is no connection to the cold valve the machine will not fill. Check the inlet hose filters are not blocked, the hoses are not kinked and are attached correctly. Check that the drain hose is not too low or pushed into the standpipe too far. This will cause the water to siphon out of the machine. Check that the cold water temperature does not exceed the 35°C temperature requirement. Check the water flow rate. It maybe too low. |

Wash load is out of balance | Touch If the out of balance persists, pause the cycle, manually redistribute the load and touch If necessary, stop the cycle, select ‘Spin' and touch If the problem persists, check that the machine is correctly levelled. |

| USER WARNINGS AND DESCRIPTIONS | WHAT TO DO |

Too many suds | Machine will stop and flash When the suds have dissipated the machine will automatically restart. If a suds event has occurred during a cycle the machine will also display this warning at the end of the cycle, to alert you that this has occurred. This may help to explain any reduction in performance. Check you are using a detergent suitable for front loaders. Check you are not overdosing the detergent. Check the standpipe height for the drain does not exceed 1000mm. |

Door is locked | The temperature in the drum is over 60°C therefore it is not safe to open the door. Wait until the temperature drops below 60°C. Check the water level in the drum. If the level is above the bottom of the door seal, the door cannot be opened. Use the ‘Add a Garment' button if you wish to add or remove items. If the drum is still moving, wait for it to stop before attempting to open the door. |

Door is open | Close the door fully and touch Try opening and closing the door again. Reposition the load, make sure the load is correctly in the drum and that protruding items are not stopping the door from closing. |

FAULT CODES

When you hear a continuous series of beeps, all the lights on the control panel are turned off, and a number appears on the digital display, a fault has occurred.

The washer will automatically enter this mode when there is a fault. The fault code will be shown as Err followed by a number on the digital display. To stop the sound, touch any button and perform the following steps:

- Turn your machine off at the power point.

- Wait one minute and turn it back on.

- Check that your machine is correctly levelled (refer to ‘Levelling the washer’).

- Remove your wash load.

- Perform a ‘Rinse’ cycle.

- If the fault re-occurs repeat steps 1 and 2.

- If the machine still does not work, you will be required to call a Fisher & Paykel service technician to arrange service (refer to ‘Customer Care’).

- Record the fault code number displayed and the serial number of your washer (located on the rear of the machine, and/or above the drum opening when the door is open) before calling. The fault code will indicate to the service technician what the problem could potentially be.

If a fault code is being displayed, you can still turn your washer off by pressing ‘POWER’.

TROUBLESHOOTING

The following is a list of problems you may encounter when using this appliance and some suggestions that may help to correct the problem. If you still have problems, contact your Fisher & Paykel trained and supported service technician.

| PROBLEM | POSSIBLE CAUSES | WHAT TO DO |

Washer not turning on

| Power not switched on at the wall. | Switch the power on at the wall. Then press ‘POWER'. |

Household power supply not working. | Try plugging in another electrical appliance. | |

Keylock may be activated. | Touch and hold the ‘Keylock' button for 3 seconds. | |

Touching Ml does not start the fill

| Washer door not closed properly. | Open and reclose door. |

The washer is waiting for a command from you. | If | |

The washer has detected a fault. | Check if a code is being displayed on the panel (refer to ‘Fault codes', page 32). | |

Hot and cold taps not turned on. | Check that both hot and cold taps are turned on (if using cold inlet only ensure inlet valve cap is installed on the hot valve on the machine). | |

Hot and cold taps not connected to the corresponding valve on the machine. | Check the cold tap is connected to the cold valve on the machine and the hot tap is connected to the hot valve. | |

Blocked hose filters. | Check the tap end of the inlet hoses for blockages. | |

Inlet hose leaking, twisted or damaged. | Check the inlet hoses for leaks or damage. Check that the inlet hoses are not twisted. | |

Faulty water supply. | Check taps that aren't connected to the machine are working. | |

Delay start maybe set. | Refer to ‘Delay start', page 24. | |

| Washer stops working mid cycle | The washer has detected a fault. | Refer to ‘User warnings', page 30 or ‘Fault codes', page 32. |

Power or water failure. | Check the power and/or water is working correctly. | |

| Washer has been paused. | Touch the button to continue | |

| Oversudsing. | Washer is waiting for suds to dissolve before continuing the cycle. |

| PROBLEM | POSSIBLE CAUSES | WHAT TO DO |

Washer drains while filling

| Drain hose too low. | Ensure the height of the drain hose is at least 600mm from the floor level (refer to ‘Draining', page 10). |

Drain hose sitting in water. | Clear the drain. | |

Washer is not draining

| Drain hose blocked. | Clear the drain hose. |

Pump filter blocked. | Clear the pump filter (refer to ‘Cleaning the pump filter', page 29). | |

Drain hose higher than 1000mm above floor level. | Lower the level of the drain hose (refer to ‘Draining', page 10). | |

Filling continuously

| Drain hose not connected to standpipe or tub. | Connect drain hose correctly (refer to ‘Attaching drain hose to spigot', page 10). |

Washer is siphoning. | Ensure standpipe or tub is at least 600mm from the floor level. | |

Poor rinsing

| Incorrect detergent used. | Use low sudsing, front loader detergent only. |

Too much detergent used. | Ensure the correct dose of detergent is used for the load size and soil level (refer to ‘Adding detergent', page 22). | |

Not spinning properly

| Load has gone out of balance. | Open door and redistribute load, then restart the washer. |

Washer is not level. | Ensure washer is correctly levelled (refer to ‘Levelling the washer', page 8). | |

Suds build up. | Check the amount of detergent used, reduce if necessary. | |

Too many soap suds

| Incorrect type of detergent used. | Use low sudsing, front loader detergent only (refer to ‘Adding detergent', page 22). |

Too much detergent used. | Ensure the correct dose of detergent is used for the load size and soil level (refer to ‘Adding detergent', page 22). | |

Inlet water pressure/ flow rate too low. | Ensure correct inlet water pressure and flow rate as per installation instructions. | |

| Small puddle of water from under the machine | Inlet hose or drain hose leaking. | Check inlet hoses and the drain hose are correctly attached and not damaged. |

Lots of suds. | Suds may have leaked and then dissolved. | |

Dispenser compartments blocked. | Refer to ‘Cleaning the dispenser drawer', page 27. | |

| Dispenser drawer not fully closed. | Close dispenser drawer fully and ensure it remains closed during the cycle. | |

| Damage to door seal. | Check seal inside door for damage. If it sustains any damage it will need to be replaced. |

| PROBLEM | POSSIBLE CAUSES | WHAT TO DO |

| Cycle time longer than usual/ inaccurate time reading/ adjustment of time remaining during cycle | Cycle time is approximate. | Cycle time is influenced by a number of factors (refer to ‘Wash cycles’, page 19). |

Low water pressure or flow rate. | Ensure that inlet hose filters are not blocked. | |

Out of balance or oversudsing. | Recovery from out of balance or oversudsing will extend cycle time (refer to ‘Caring for your washer’, page 27). | |

Washing a large load. | Be aware that it will take longer for the machine to fill. | |

Selecting various options. Dispenser drawer not properly closed or was opened part way through the cycle. | Be aware that some options will extend cycle time. | |

| Detergent or fabric softener remaining in dispenser at the end of the cycle | Ensure the dispenser drawer is fully closed at the start of the cycle and remains closed throughout the cycle. | |

Dirty or blocked dispenser. | Clean the dispenser drawer | |

Liquid sitting at the ‘Max' level at the end of the cycle indicates a blockage. | Clean the fabric softener dispenser compartment. (Refer to ‘Cleaning the dispenser drawer’, page 27). | |

Dispenser over loaded with detergent. | Clean out remaining detergent (refer to ‘Adding detergent’, page 22). | |

Composition of the detergent makes it difficult to dispense. | Add detergent to the ‘MAIN WASH Powder’ detergent compartment instead. | |

| Washing very wet at the end of the cycle | Cycle selected not appropriate. | Particularly short or delicate cycles have shorter spins which can result in wetter washing at the end of the cycle. |

| Incorrect spin speed for load selected. | Select a faster spin speed. | |

| An out of balance load has occurred. | The washer compensates for the out of balance by using a lower spin speed, to reduce noise and potential damage to itself. | |

| Vibrating | Transit bolts left in place. | Ensure transit bolts are removed prior to use of the machine (refer to ‘Removing transit safety bolts’, page 5). |

| Washer may not be level. | Ensure washer is installed on an appropriate surface and levelled correctly (refer to ‘Levelling the washer’, page 8). | |

| Load is out of balance. | Wash an average sized load rather than a smaller load or a single item. Washing one item at a time is not recommended as it is difficult for the washer to balance a single item during spin. |

PROBLEM | POSSIBLE CAUSES | WHAT TO DO |

Creasing | Washer overloaded. | Do not overload washer. |

Incorrect cycle for load type. | Use the ‘Easy Iron' or ‘Handwash' cycle for creasable items. | |

Spin speed too fast. | Select a slower spin speed. | |

Wet clothes left in washer or laundry basket. | Laundry left sitting wet is more likely to crease. If not removing clothes from washer immediately at end of cycle, select the ‘Wrinkle Free' option. Do not leave wet washing sitting in a washing basket. | |

Wash temperature too hot for load type. | Select a lower wash temperature. Check items care label for correct care. Check the hot and cold taps are connected to the correct valves (refer to ‘Connecting to the water supply', page 8). | |

Items not sorted correctly. | Sort load so that items of similar weight are washed together. | |

Poor soil removal | Incorrect wash cycle selected. | Select a wash cycle that is appropriate for the amount of dirt (refer to ‘Wash cycles', page 19). |

| Insufficient detergent. | Ensure the correct dose of detergent is used for the load size and soil level (refer to ‘Adding detergent', page 22). | |

| Washer overloaded. | Ensure the washer is not overloaded in terms of its capacity or the cycle selected (refer to ‘Loading', page 22). | |

| Items require a longer wash time. | Select a higher soil level option if available. | |

| Load was particularly dirty. | Select ‘Pre Wash' for particularly dirty loads (refer to ‘Customising wash cycle', page 24). | |

| Items not sorted correctly. | Wash heavily and lightly soiled garments separately. | |

| Washer dirty from previous wash. | After washing particularly dirty clothing, we recommend putting the washer through a ‘Rinse' cycle once the load has been removed. This washes away any remnants of dirt that could affect future wash performance. | |

| Incorrect wash temperature selected in relation to the type of soil. | Select a wash temperature suitable for the type of soil, eg warm for greasy soils, cold for muddy soils. Increasing the wash temperature generally improves soil removal and overall wash performance. | |

| Ensure garments can be washed at the increased temperature. |

| PROBLEM | POSSIBLE CAUSES | WHAT TO DO |

| Dye transfer | Coloured items not washed separately from white/ light coloured items. | Remember to separate whites and colours. |

New or non-colourfast items not washed separately. | Wash non-colourfast items separately and select ‘Cold' wash temperature. | |

Wet items have been left sitting for too long. | Remove items from washer as soon as the cycle is finished, or if items are not to be removed from the washer immediately select ‘Wrinkle Free'. | |

Wash temperature. | Consider the wash temperature you select for your coloured items. Lower the temperature if you are concerned. | |

| Black or grey marks on clothes | Correct amount of detergent. | Ensure the correct dose of detergent is used for the load size and soil level (refer to ‘Adding detergent', page 22). |

Washer needs to be cleaned. | Empty the machine and complete a ‘Drum Clean' cycle (refer to ‘Cleaning the drum and the door', page 28). | |

| Tangling | Items not sorted correctly. | Separate larger items from smaller items. |

| Washer loaded incorrectly. | Load items loosely and individually into the washer (ie not folded). | |

| Incorrect cycle for load type selected. | Use the ‘Easy Iron' cycle to wash shirts. | |

| Overloaded in terms of its capacity or the cycle selected. | Try washing average to smaller load sizes. | |

| Delicate items. | Wash pantyhose, bras and any other delicate items prone to tangling in a mesh laundry bag. |

See other models: DD60SCTW9 DE7060P2 CG244DLPX1_N DE5060MU2 OR90SCI6W1

-513263.png)

-899588.png)

-987245.png)

-631818.png)

-462504.png)

-224304.png)

-81324.png)

-58415.png)