Loading ...

Loading ...

Loading ...

- 8

Maintenance to be carried out after 50

operating hours:

Have the first maintenance performed

by the customer service in accordance

with the inspection check list.

Maintenance to be carried out after 250

operating hours:

Have the maintenance performed by

the customer service in accordance

with the inspection check list.

In order to safeguard warranty claims, all

service and maintenance work during the

warranty period must be carried out by the

authorised Kärcher Customer Service in

accordance with the maintenance booklet.

Preparation:

Park the sweeper on an even surface.

Turn ignition key to "0" and remove it.

Lock parking brake.

DANGER

Risk of injury! Always apply the safety bar

when the waste container is raised.

Perform the safeguarding only from outside

the hazard zone.

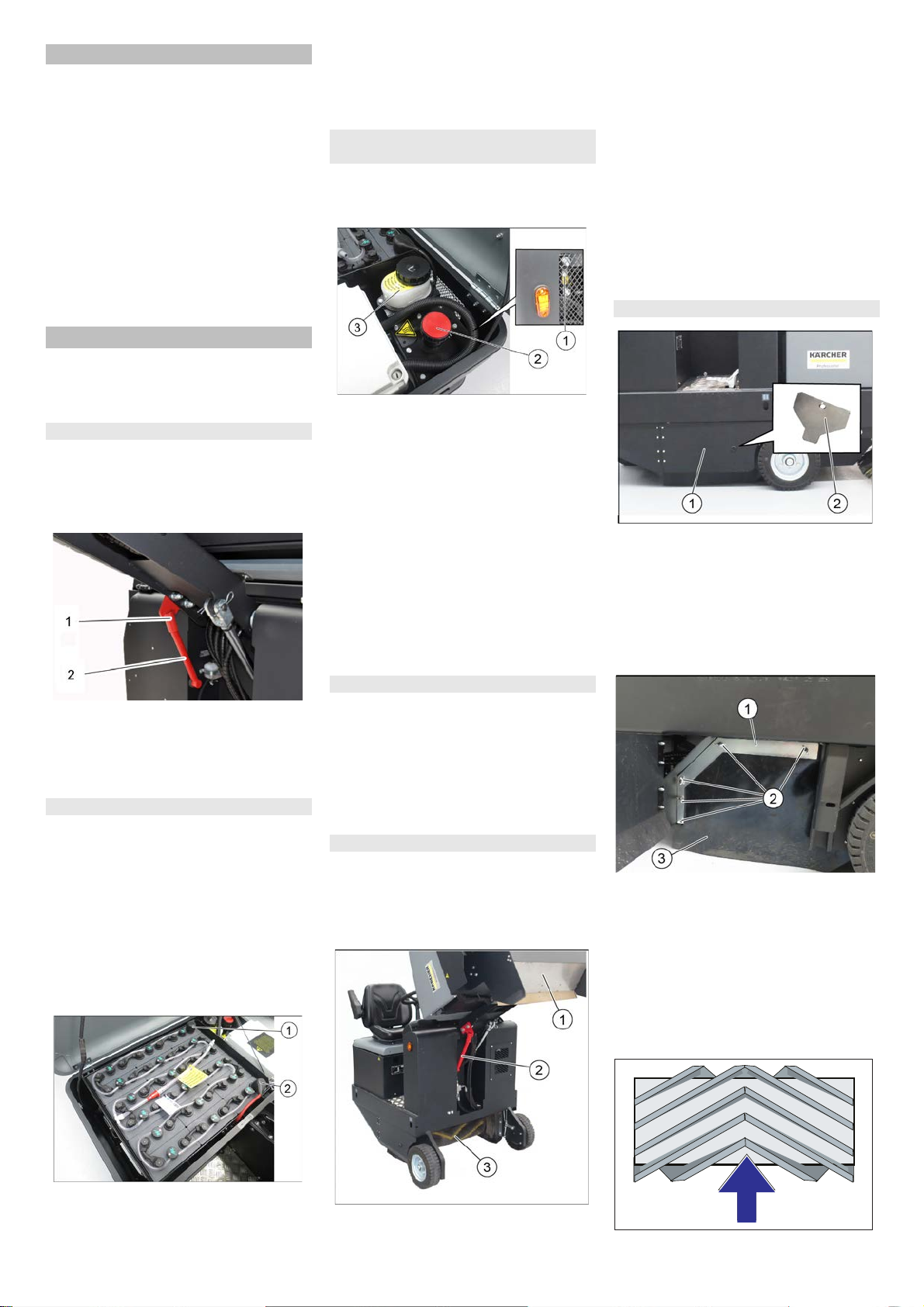

1 Holder of safety rod

2 Safety rod

Fold the safety rod for the high empty-

ing up and insert it into the holder (se-

cured).

ATTENTION

Observe the orientation of the battery ter-

minals when installing the batteries. Battery

terminals are installed on the left in the di-

rection of travel.

The batteries can only be exchanged as a

set. The exchange has to be performed by

trained personnel.

Due to the heavy weight (300 kg), the

batteries must be exchanged using a

crane.

Battery terminals - travel direction left

1 Negative terminal

2 Positive terminal

When removing the battery, disconnect

the negative terminal wire first.

Fasten the crane chains in the four eye-

lets of the battery set and carefully lift

out the batteries.

NOTICE

The waste container must not be raised.

Open the engine hood.

1 Looking glass

2 Screw cap, oil fill opening

3 Container (without function)

Check hydraulic oil level in the looking

glass.

– The oil level must lie between “MIN“

and “MAX“ marking.

– Add hydraulic oil if the oil level is below

the "MIN" marking.

Loosen the closing cap of the oil filling

opening.

Clean the filling area.

Refill hydraulic oil.

Oil grade: see Technical Data

Replace and tighten the closing cap of

the oil filling opening.

Lock parking brake.

Start the motor.

Only the authorised customer service is

permitted to carry out maintenance tasks

on the hydraulic unit.

Check all hydraulic hoses and connec-

tions and ensure that they are leak-

proof.

DANGER

Risk of injury! Always apply the safety bar

w

hen the waste container is raised.

Perform the safeguarding only from outside

the hazard zone.

1 Waste container

2 Safety rod

3 Roller brush

Switch off device.

Lift the emptied waste container to the

end position. The roller brush is visible.

Secure the waste container. See chap-

ter "Securing the raised waste contain-

er".

Turn ignition key to "0" and remove it.

Check the roller brush for damage, re-

move wrapped tapes or cords.

Fold the safety rod down into the recep-

tacle (raised waste container is unse-

cured).

Lower the waste container up to the

end-position.

1 Side panel, right

2 Key for roller brush access

Lift the emptied waste container to the

end position.

Secure the waste container. See chap-

ter "Securing the raised waste contain-

er".

Open the side covers using a key.

1 Holding bow

2 Wing nut

3Side seal

Unscrew the wing nuts.

Remove the retaining clamp.

Flip the side seal out.

Uncscrew the retaining screw of the

roller brush intake, and swing the intake

to the outside.

Pull out roller brush.

Maintenance by Customer Service

Maintenance Works

Securing the raised waste container

Replace batteries

Check hydraulic oil level and refill

hydraulic oil

Check hydraulic unit

Checking roller brush

Replacing roller brush

24 EN

Loading ...

Loading ...

Loading ...