Loading ...

Loading ...

Loading ...

KBF / KBF-UL + KMF (E6) 04/2020 page 79/163

11.5 Activating / deactivating the audible alarm (alarm buzzer)

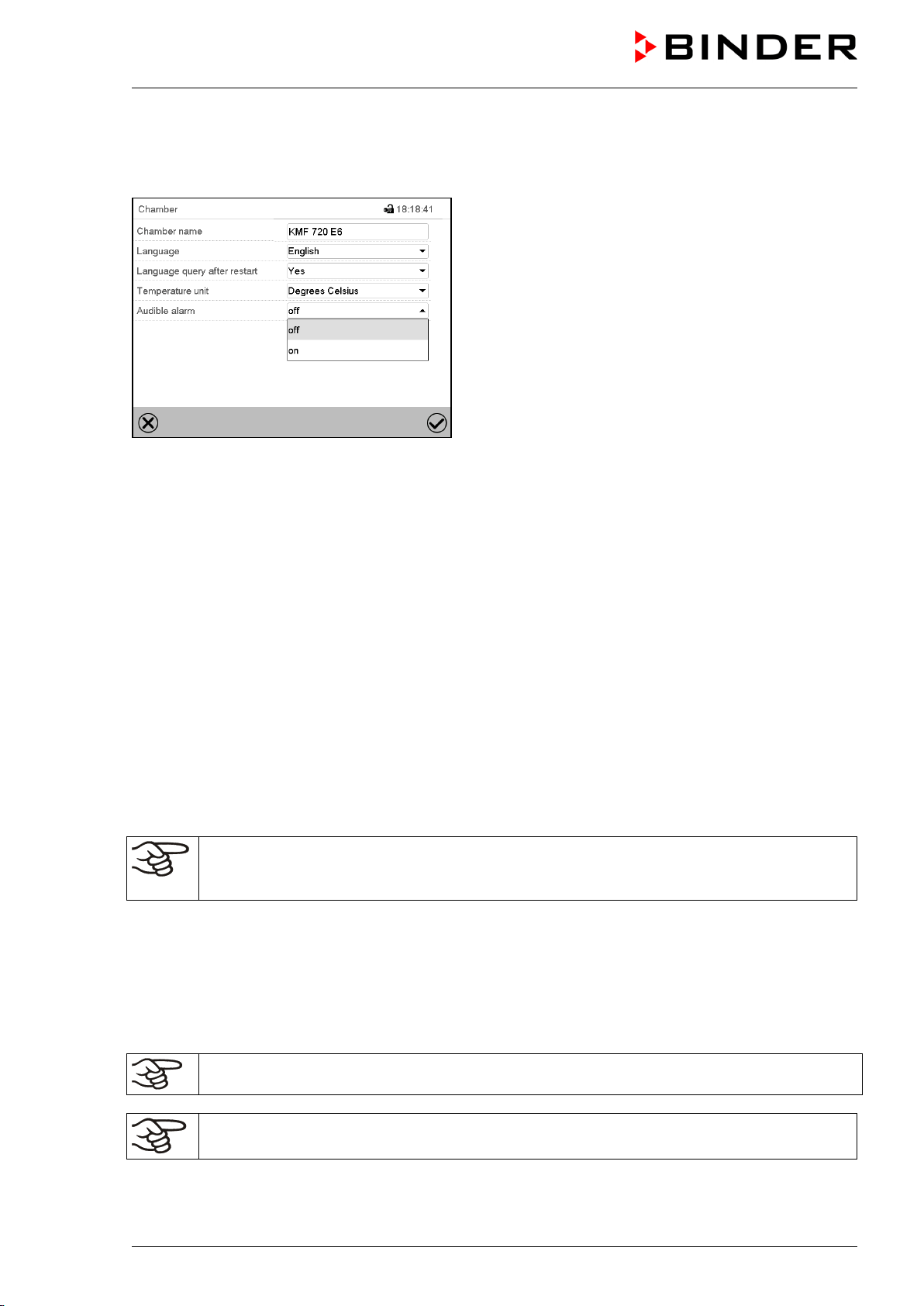

Path: Main menu > Settings > Chamber

“Chamber” submenu (example).

In the field “Audible alarm” select the desired setting

“off“ or “on” and press the Confirm icon.

12. Temperature safety devices

12.1 Over temperature protective device (class 1)

The chamber is equipped with an internal temperature safety device, class 1 acc. to DIN 12880:2007. It

serves to protect the chamber and prevents dangerous conditions caused by major defects.

If a temperature of approx. 110 °C / 230 °F is reached, the over temperature protective device perma-

nently turns off the chamber. The user cannot restart the device again. The protective cut-off device is

located internally. Only a service specialist can replace it. Therefore, please contact an authorized service

provider or BINDER Service.

12.2 Overtemperature safety controller class 3.1

The chambers are regularly equipped with an electronic overtemperature safety controller (temperature

safety device class 3.1 according to DIN 12880:2007). The safety controller is functionally and electrically

independent of the temperature control system. If an error occurs, it performs a regulatory function.

With option temperature safety device class 3.3 (chap. 12.3), the safety controller is not used.

It must be set to the maximum limit value (KBF / KBF-UL: 70 °C / 158 °F, KMF: 100 °C /

212 °F).

Please observe the DGUV guidelines 213-850 on safe working in laboratories, issued by the employers’

liability insurance association (for Germany).

The overtemperature safety controller serves to protect the chamber, its environment and the contents

from exceeding the maximum permissible temperature. In the case of an error, it limits the temperature

inside the chamber to the entered safety controller set-point. This condition (state of alarm) is indicated

visually and additionally with an audible alert if the buzzer is enabled (chap. 11.5). The alarm persists until

the chamber cools down below the configured safety controller setpoint.

Check the setting regularly and adjust it following changes of the set-point or charge.

The safety controller only activates after the set-point has been reached once.

Loading ...

Loading ...

Loading ...