Loading ...

Loading ...

Loading ...

46

HBG EVAPORATOR OPERATOR’S MANUAL

HBG • 8.913-990.0-K

TROUBLESHOOTING

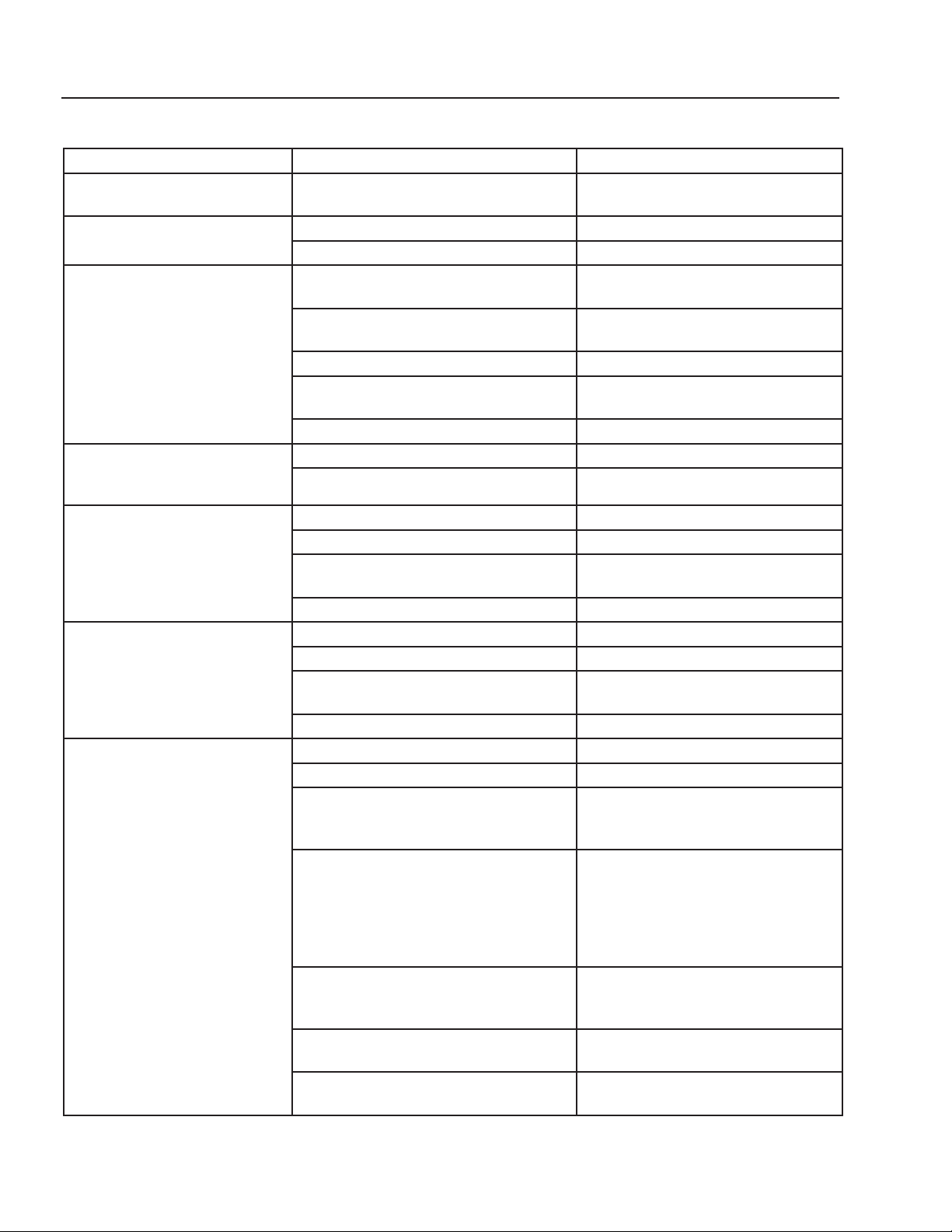

PROBLEM POSSIBLE CAUSE SOLUTION

BURNER WON’T SHUT

DOWN AT LOW WATER

Low water fl oat does not work Check switch for continuity, then

adjust or replace.

WATER WON’T HEAT UP

OR HEATS UP TOO SLOWLY

Sludge buildup on fl oor or tank Scrape sludge from bottom of tank.

Incorrect gas supply for burner Recheck manifold. Reset if needed.

AIR PUMP

WON’T START

Long fl oat, top micro switch not

energized. Water too high

Keep evaporating or

manually lower the water level.

Air regulator setting adjusted too low Readjust air regulator to between 50

and 100 psi.

Air pump solenoid plugged Clean out.

No voltage to air pump solenoid coil Check wiring in electrical box.

Replace parts as needed.

Bad air pump solenoid coil Replace solenoid coil.

WASTEWATER

DISCHARGING FROM

AIR PUMP EXHAUST

Check for diaphragm rupture If ruptured, replace.

Check for diaphragm nut Tighten nut.

AIR BUBBLES IN

DISCHARGE HOSE

Check connections of suction plumbing If loose, retighten.

Check band clamps on intake manifold If loose, retighten.

Check o-rings between intake manifold

and fl uid caps

Replace

o-rings if worn.

Check tightness of diaphragm nut Tighten nut.

AIR PUMP BLOWS AIR

OUT MAIN EXHAUST

WHENSTALLED ON

EITHER STROKE

Check U cups on spool in major valve Replace if needed.

Check valve plate and insert for wear Replace if needed.

Check sleeve and o-ring on diaphragm

connecting rod

Replace if needed.

Check o-rings on piston for wear Replace if needed.

LOW DISCHARGE G.P.M.

Check air supply Adjust to between 50 and 100 psi.

Check for plugged discharge hose Unplug discharge hose.

For the pump to prime itself it must be

mounted in a vertical position so that

the balls will check by gravity

Level machine.

“Check for pump cavitation - suc-

tion pipe should be 1/2”” minimum or

larger if high viscosity fl uids are being

pumped. Suction hose must be non-

collapsible type, capable of pulling a

high vacuum”

Replace hoses if undersized.

Check all joints on intake manifolds

and suction connections. These must

be air tight

Tighten all joints and connections.

Check for sticking or improperly seating

check valves

Clean check valves.

If pump cycles at a high rate or runs er-

ratically, check piston o-rings for wear

Replace

o-rings if needed

Loading ...

Loading ...

Loading ...