Loading ...

Loading ...

Loading ...

12

HBG EVAPORATOR OPERATOR’S MANUAL

HBG • 8.913-990.0-K

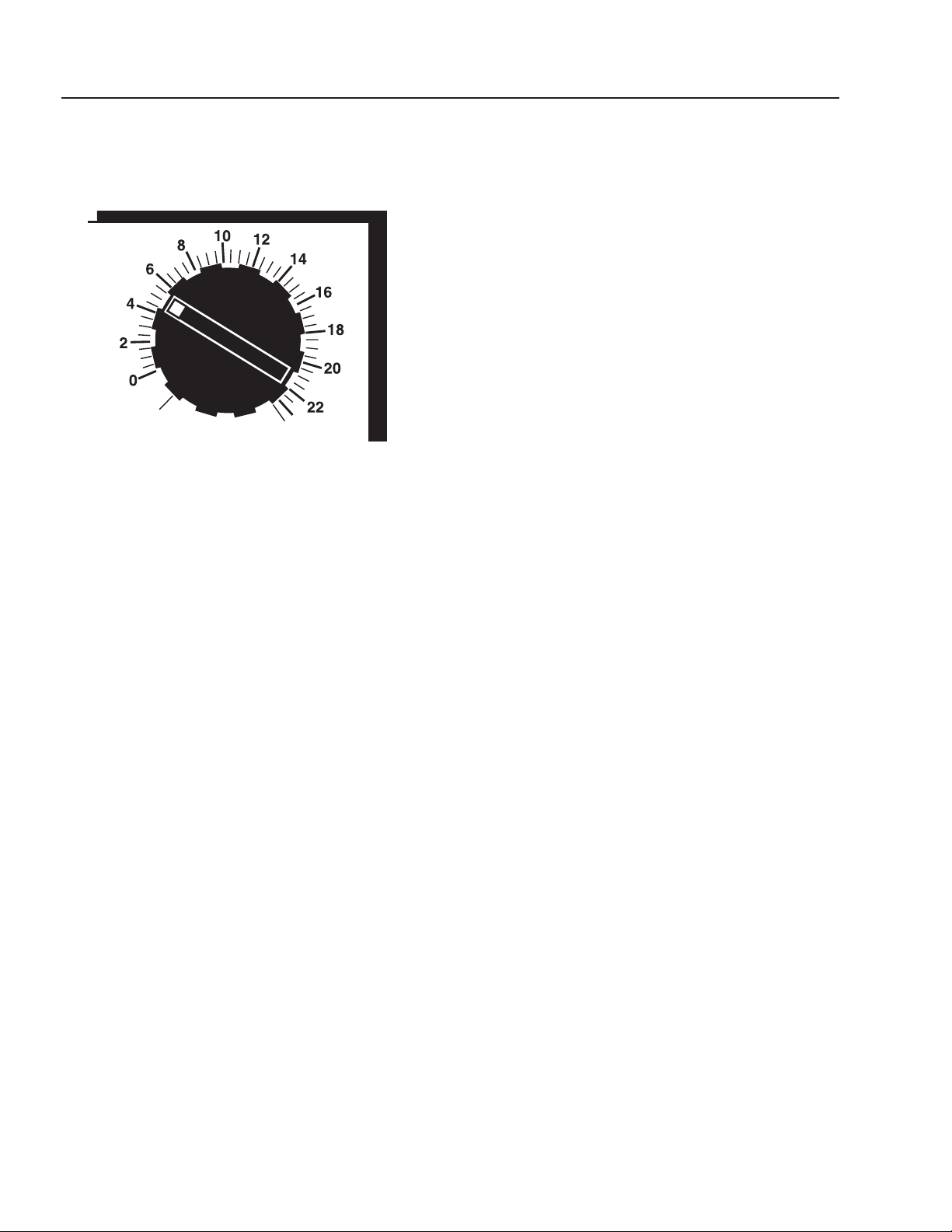

SETTING LIMIT CONTROL

Adjust the high limit control temperature accordiningly.

MAINTENANCE

CAUTION: Use protective gloves, goggles and any

oth er protective clothing re quired by law for chem i-

cals mixed with the waste stream.

The HBG does not require a lot of main te nance, but it

does require con sis tent main te nance. The fre quen cy of

main te nance var ies de pend ing on what is in the water

that is be ing evap o rat ed.

Gen er al maintenance consists of re mov al of sludge from

the bottom and removal of any fl oat ing oil at the top of

the evap o ra tion tank.

WARNING - Shut down the HBG and allow it to cool

be fore performing any main te nance. Do not al low

pump to run long er than 5 min utes with out wa ter.

Dis con nect all hos es to allow wa ter to drain.

OIL REMOVAL - If you have excess fl oating oil in the

evaporation tank liq uid that needs to be re moved, shut

down the HBG and let the oil fl oat to the top. Attach oil

skimmer to side of tank and plug into own power source.

Turn on the oil skim mer and col lect oil in a buck et.

SLUDGE REMOVAL - Remove the low er 3" sludge

drain cap on the side of the evaporator allowing sludge

and wa ter to es cape. Use a small shovel to remove the

re sid u al sludge from the bottom of the tank. Removing

the sludge and clean ing the fl oor of the evap o ra tor will

great ly im prove the evap o ra tion rate.

NOTE: Allowing sludge to ac cu mu late on the fl oor of the

HBG can cause warpage, corrosion and or heat stress to

the fl oor. A build-up of solids will cause the manual reset

high tem per a ture switch to trip not al low ing the burn er

or pump to op er ate. Remove the sludge, refi ll the tank

and restart the machine.

WARNING: Allowing sludge to build up on the in side

fl oor of the HBG can cause warpage to the fl oor of

the tank and will void the warranty.

DRAFT INDUCER: On a monthly main te nance sched-

ule, clean ing of the fan blade fi ns and ex haust stack ing

must be done to re move any sludge build-up that can

re duce the evap o ra tion ef fi cien cy. To clean the fan blade

fi ns, start with the water cool and the fan switch on the

control panel in the off po si tion. Next, remove the six tek

screws that at tach the fan to the stack. Pull the in duc er

fan away from stack and scrape debris from blade fi ns.

On reassembly, place a small bead of high heat sil i cone

around the outer edge of the in duc er housing on each

tek screw to seal out any pos si ble air leaks.

WEEKLY MAINTENANCE

1. Turn all power switches to the “OFF” position.

2. Allow the wastewater to cool.

3. Position a sludge container under the sludge valve.

Open the sludge valve and remove the remaining

waste liq uid.

4. After every batch is complete, scrape the fl oor and

in te ri or walls of the HBG tank, transferring the sludge

into the sludge con tain er.

5. Remove any buildup that has accumulated on the

ex te ri or of the tank and exhaust pipe.

6. Clean the liquid level fl oats, remove any ac cu mu la-

tion that may coat the fl oats and not allow them to

move freely.

7. Clean all three wastewater fi lter screens if auto fi ll

option is installed. (i.e. both inlet strainers and one

underneath the Parker solenoid brass cap)

8. If the evaporator is not in use at least twice per week,

then clean out and rinse with fresh water, and let sit

empty.

9. Check tank and lid for corrosion after each com plete

batch.

500° for HBG-15 & HGB-30

Loading ...

Loading ...

Loading ...