Loading ...

Loading ...

Loading ...

HBG EVAPORATOR OPERATOR’S MANUAL

13

HBG • 8.913-990.0-K

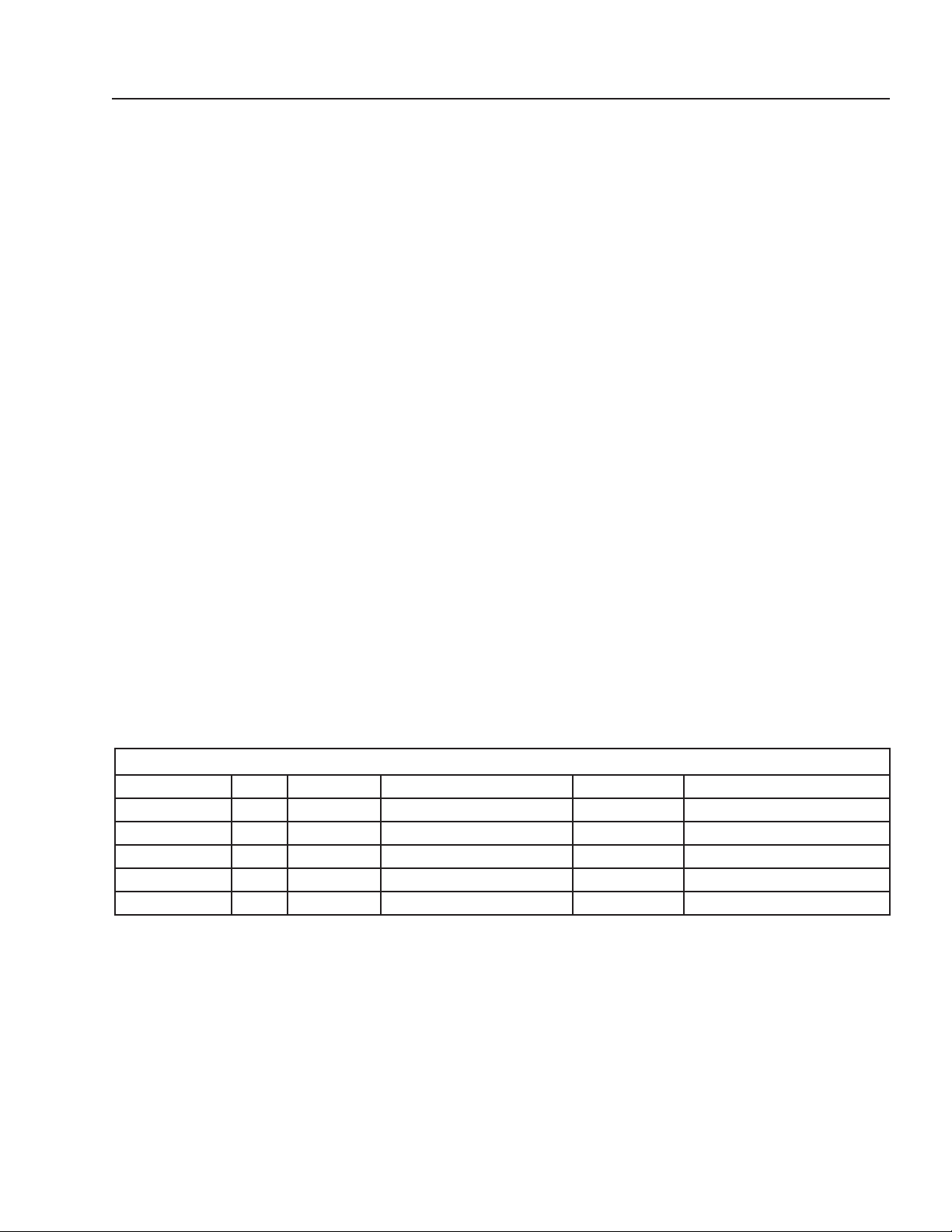

HBG FUEL AND AIR SETTINGS

Natural Gas GPH Gas Orifi ce Inlet Gas Supply Pressure Man. Pressure Air Setting

HBG-15D 10 - 15 G (.261) 4.5 - 14 WCI 3 WCI Open Draft Wheel 6 Full Turns

HBG-30D 25 - 30 T (.468) 5.5 - 14 WCI 3 WCI Draft Open to 4

Liquid Propane GPH Gas Orifi ce Inlet Gas Supply Pressure Man. Pressure Air Setting

HBG-15D 10 - 15 #22 (.157) 11 - 14 WCI 5 WCI Open Draft Wheel 6 Full Turns

HBG-30D 25 - 30 Q - (.332) 5.5 - 14 WCI 5 WCI Draft Open to 8

SEMI ANNUAL MAINTENANCE

1. Check auto fi ll pump for proper pressure, fl ows and

electrical capacities.

2. Check auto fi ll fl oats for proper operation.

3. Oil the draft inducer motor bearings. Oil holes are

pro vid ed at front and rear faces of motor. CAUTION:

Not more than 3 drops of S.A.E. 20 oil should be

used.

4. Check tank and lids for corrosion.

5. Check burner for proper operation and gas

pres sure.

AUTO FILL OPERATING

CHARACTERISTICS

The auto fi ll option consists of two level control switches

which control the fi ll pump. The lower level switch turns

the pump on. As the wa ter level raises, the upper level

switch turns the pump off. The evaporator then evap o-

rates the water, which in turn lowers the water lev el past

the low er level switch, which turns the pump on and

starts the fi ll pro cess.

NOTE: To engage the auto fi ll feature, push the pump

switch to auto. This will allow the pump to be con trolled

by the auto fi ll fl oat level switches. Push ing the pump

switch to man u al will bypass the external N/O teth ered

fl oat in the waste wa ter holding tank.

AIR ASSISTED

DEFOAMER OPERATING

CHARACTERISTICS

The air assisted defoamer option consists of a metering

pump drawing up defoamer and a solenoid controlling the

air injecting the defoamer through a fan nozzle lo cat ed

in side the wastewater tank. Set the three position switch

to “auto” and de foam er will then be injected every time

the machine refi lls. If more defoamer is needed, turn

ad just ment screw, located under cover plate in front

of pump, clockwise to increase pump speed. Injecting

man u al ly is also avail able. NOTE: The air pres sure

need ed to op er ate the de foam er must not ex ceed 2 psi.

Loading ...

Loading ...

Loading ...