Loading ...

Loading ...

Loading ...

27

ENGLISH

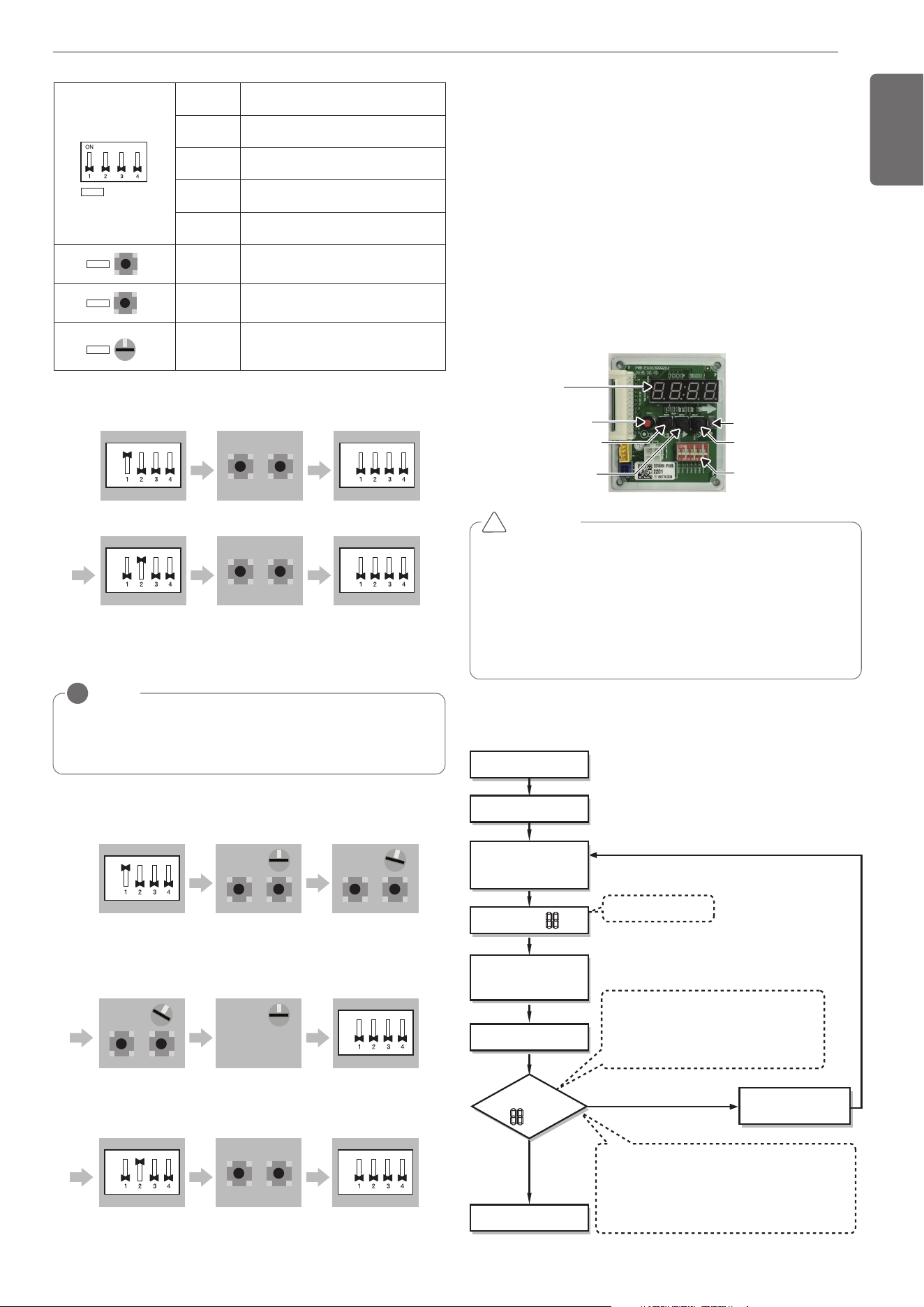

DIP-SWITCH

SW01D(reset)

SW04C(x:cancel)

7-Segment

SW03C(▶:forward)

SW02C(◀:backward)

SW01C(●:confirm)

CAUTION

• In replacement of the indoor unit PCB, always perform Automatic

addressing setting again (At that time, please check about using

Independent power module to any indoor unit.)

• If power supply is not applied to the indoor unit, operation error

occur.

• Automatic Addressing is only possible on the master Unit.

• Automatic Addressing has to be performed after 3 minutes to im-

prove communication.

!

The Procedure of Automatic Addressing

• Automatic addressing setting end

Numbers of indoor unit connection set whose

addressing is completed are indicated for 30seconds

on 7-segment LED after completing setting

Indoor address number is displayed on wired remote control or

indoor unit display window. It is not an error message, will

disappeared when on/off button is pressed on remote control

ex) Display of 01, 02, ..., 15 means connection of 15 indoor units

and Automatic addressing is completed normally.

Automatic addressing start

Waiting 3 minutes

Power On

Press RED Button

for 5 seconds.

(SW01C)

7-segment LED = 88

Don’t press RED Button

(SW01C)

Waiting about 2~7 minutes

7-segment LED

OK

YES

NO Check the connections

of communication cable

= 88

Automatic Addressing

The address of indoor units would be set by Automatic Addressing

- Wait for 3 minutes after supplying power.

(Master and Slave outdoor units, indoor units)

- Press RED button of the outdoor units for 5 seconds. (SW01C)

- A “88” is indicated on 7-segment LED of the outdoor unit PCB.

- For completing addressing, 2~7 minutes are required depending on

numbers of connected indoor units

-

Numbers of connected indoor units whose addressing is completed are

indicated for 30 seconds on 7-segment LED of the outdoor unit PCB

- After completing addressing, address of each indoor unit is indicated

on the wired remote control display window. (CH01, CH02,

CH03, ……, CH06 : Indicated as numbers of connected indoor units)

[Heat Recovery (SERVICE PCB)]

S/W No. Setup

No.1

Manual addressing of valve #1 (Master)

/ #5 (Slave)

No.2

Manual addressing of valve #2 (Master)

/ #6 (Slave)

No.3

Manual addressing of valve #3 (Master)

/ #7 (Slave)

No.4

Manual addressing of valve #4 (Master)

/ #8 (Slave)

SW02B

SW02B

Increase in the digit of 10 of valve ad-

dress

SW01B

SW01B

Increase in the last digit of valve ad-

dress

SW01C

0

SW01C

Manual addressing of zoning indoor

units

* Use for Zoning setting

SW01E

SW01E

SW #1 On : Select Valve #1

Master

ON

OFF

SW02B SW01B

Input the central control

address of Indoor unit

Master

SW01E

SW #1 Off : Finish Valve #1

Master

ON

OFF

SW01E

SW #2 On : Select Valve #6

Slave

ON

OFF

SW02B SW01B

Input the central control

address of Indoor unit

Slave

SW01E

SW #2 Off : Finish Valve #6

Slave

ON

OFF

1) Normal setting (Non-Zoning setting)

ex) Manual pipe detection of Valve #1, 6.

SW01E

SW #1 On : Select Valve #5

Slave

ON

OFF

SW02B SW01B

SW01C

After selecting No.1 zoning

indoor unit, input the central

control address of indoor unit.

Slave

After selecting No.2 zoning

indoor unit, input the central

control address of indoor unit.

Setting SW01C to ‘0’After selecting No.3 zoning

indoor unit, input the central

control address of indoor unit.

SW01E

SW #1 Off : Finish Valve #5

Slave

ON

OFF

SW01E

SW #2 On : Select Valve #6

Slave

ON

OFF

SW02B SW01B

Input the central control

address of Indoor unit

Slave

SW01E

SW #2 Off : Finish Valve #6

Slave

ON

OFF

0

SW02B

SW01C

SW01B

Slave

1

SW01C

Slave

0

SW02B

SW01C

SW01B

Slave

2

NOTE

!

Use the Zoning Control when install two or more indoor units at 1 branch of HR

Unit.

The indoor units controlled by Zoning Control can be selected collectively as the

cooling/heating mode.

2) Zoning setting

ex) Manual pipe detection of Valve #5 with three zoning indoor units,

#6 without zoning unit.

1,MFL69717904,영영 18. 8. 29. 영영 2:50 Page 27

Loading ...

Loading ...

Loading ...