Loading ...

Loading ...

Loading ...

7

• To ensure correct efciency, the pipe should be as short as possible.

• Coat refrigerant oil on the connector and the are nut.

• When bending the pipe, the bend diameter should be as large as

possible to prevent the pipe from breaking or kinking.

• When connecting the pipe, center it and thread the nut by hand.

• Then tighten it with the double spanners.

• Don't let any debris such as sand, water etc into the pipe.

Pipe connection method:

When fastening and loosing the nut,

operate with double spanners, because

only one spanner cannot execute rmly.

If threading the nut as not aiming at

the center, the screw thread will be

damaged, further it will cause leakage.

Spanner

Connector

Nut

Spanner

Cautions in piping installation:

• When welding the connector use hard solder, charge nitrogen into the pipe to prevent oxidation. If not the oxygen lm in

the pipe will clog the capillary and the expansion valve. May even cause a deadly accident.

• The refrigerant pipe should be clean. If water or any other impurities enter the pipe, charge with nitrogen to clean the

pipe. The nitrogen should ow around the pressure of 72.5PSI(0.5Mpa). When charging the nitrogen, stop up the end of

the pipe by hand to enhance the pressure in the pipe, then move your hand to stop up the other end of the pipe.

• The piping installation should be done while the stop valves are closed.

• Before welding the valve and the pipes, use a wet cloth to cool down the valve and the pipes.

• When the connection pipe and branch pipe need to be shortened, please use special shears. Do not use a saw.

(5) Refrigerant pipe connection

Pipe material and specs selection

1. Please select the refrigerant pipe of the below material.

Material: the phosphoric oxidize seamless copper pipe, model: C1220T-

1/2H (diameter is over 19.05); C1220T-0 (diameter is below 15.88).

2. Thickness and specs:

Conrm the pipe thickness and specs according to the pipe selection

method(the unit is with R410A, if the pipe over 19.05 is 0-type, the

pressure preservation will be bad, thus it must be 1/2H type and over

the min. thickness.

3. The branch pipe must be from Haier.

4. When installing the stop valve, refer to the relative operation instruction.

5. The pipe installation should be in the allowable range.

6. The installation of branch pipe and gather pipe should be performed

according to the relative manual.

Drain pipe disposal

• Make sure the drain works properly.

• In regions where buildups of snow can

be expected, the accumulation and

freezing of snow in the space between

the heat exchanger and external plate

may lower operating efciency.

• After punching the knock-out hole, the

application of repair-type paint on the

surface around the edge sections is

recommended to prevent rust.

Installation instruction

If the coating on the fastening area is stripped off, the nuts rust easily.

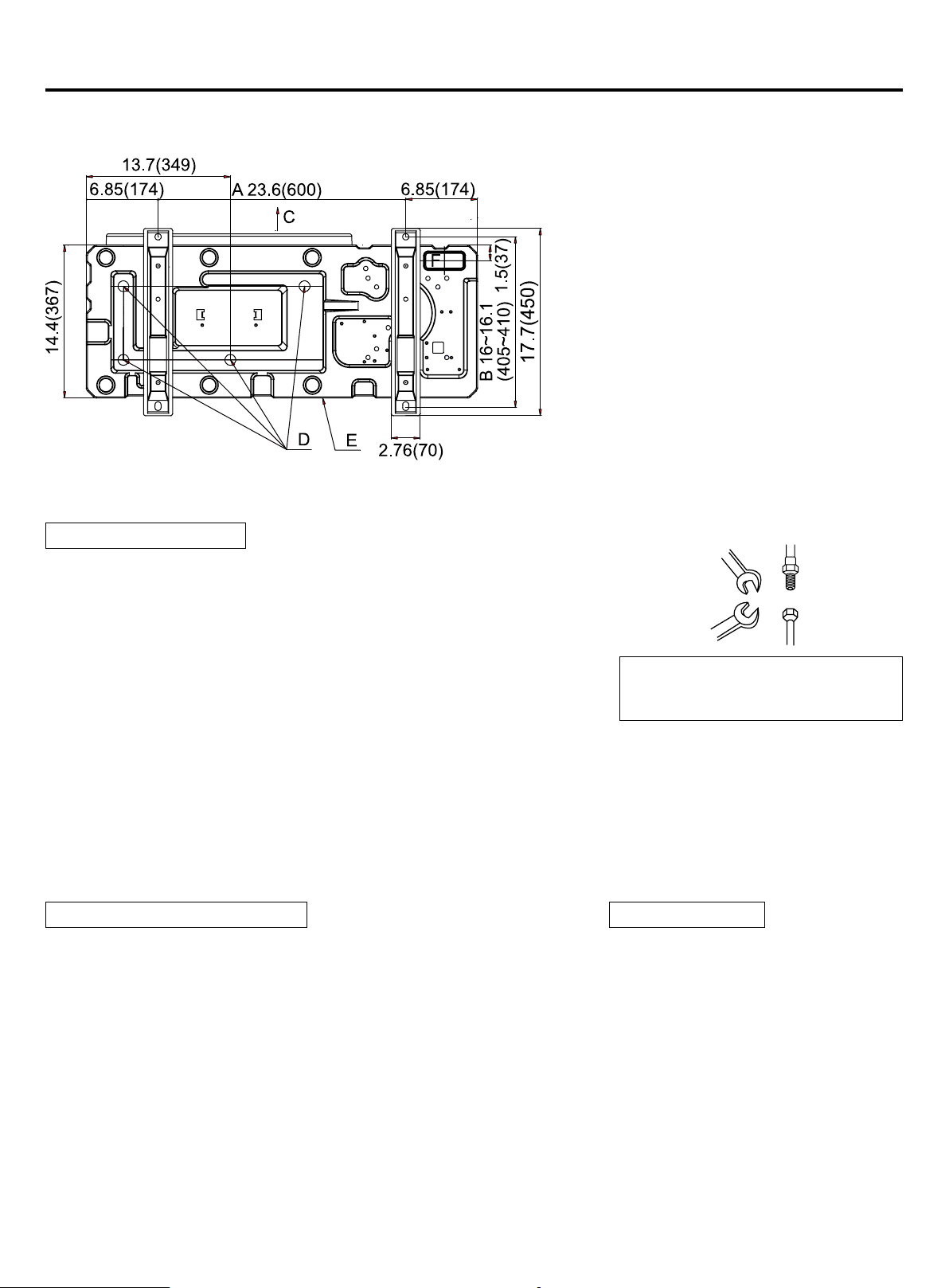

Dimensions (bottom view) (unit of measurement: mm)

A leg pitch1

B leg pitch2

C Front grill (air outlet side)

D Drain hole

E Bottom frame

F Knock-out hole (for piping line)

Loading ...

Loading ...

Loading ...