Loading ...

Loading ...

Loading ...

12

Installation instruction

Add additional refrigerant under the liquid state with the gauge.

If the additional refrigerant can not all be added, when the outdoor stops, charge it using trial mode.

If the unit runs for a long period undercharged, the compressor will eventually fail.(charging must

be nished within 30 minutes especially when the unit is running while charging).

A. Charge amounts from the factory exclude the refrigerant in the pipes.

B. The unit is charged with a standard amount of refrigerant (distributing pipe length is 0).

Additional charge amount=actual length of liquid pipe x additional amount per meter liquid pipe

Additional charge amount=L1×0.113+L2×0.073+L3×0.037+L4×0.015

L1: total length of 5/8"(15.88) liquid pipe L2: total length of 1/2"(12.7) liquid pipe

L3: total length of 3/8"(9.52) liquid pipe L4:total length of 1/4"(6.35) liquid pipe

C. Refrigerant charging and additional charge

Note:

• To prevent adding different oils into the pipe, please only use a gauge manifold and charging hose for R410A.

• Tank color for R410A is pink.

• Do not use a charging cylinder because R410A will change when transferring to the cylinder.

• When charging refrigerant, the refrigerant should be taken out from the tank as liquid state. Mark the refrigerant amount

added that was calculated by the pipe length on the unit label.

Secure refrigerant piping

• During operation, the pipe will vibrate, expand or shrink. If not being secured, the refrigerant will focus on one part and

cause the pipe to break.

• To prevent stressing the pipe, secure the pipe every 6.56-9.84ft.(2-3m).

Tighten as per the torque table below:

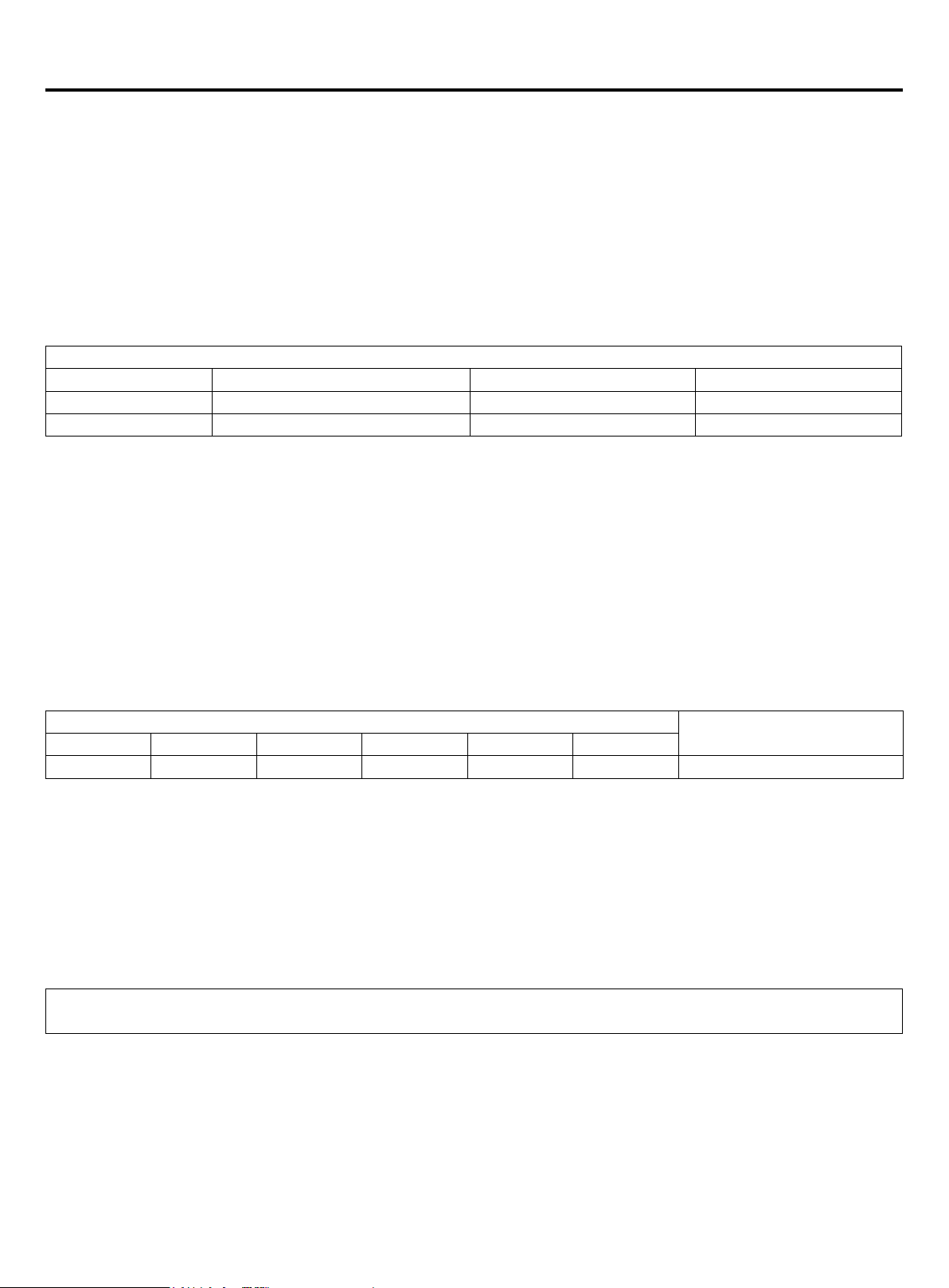

Tighten torque Ib.in(N.m)

Shaft (valve body) Cap (cover) T-shape nut (check joint)

For gas pipe less than 61.9(7) less than 265.2(30) 114.9(13)

For liquid pipe 69.4(7.85) (MAX138.8(15.7)) 260(29.4)(MAX346.5(39.2)) 77.8(8.8) (MAX130(14.7))

Additonal refrigerant charging per Ib (Ib/ft.)

Charge when out of factory

Ø5/8" Ø1/2" Ø15.88 Ø3/8" Ø1/4" Ø6.35

0.113 0.073 0.037 0.11 0.015 0.022 Refer to label

GWP: 2088

The product contains uorinated greenhouse gases and its functioning relies upon such gases.

(9) Additional refrigerant charging

• Start: press Start and Stop keys on the main control board at the same time for 5 seconds. The unit will start automatic

recovery mode. The compressor starts, the right side of the unit C0 and Ps LEDs start ashing, runs for around 3

minutes.

• Operation: when the LEDs C1 and Ps alternately ash, manually shut off the liquid pipe valve

• Off valve: when Ps < 1kg, LED displays C2, quickly close the shut-off valve, after 5 seconds the system will shut down.

• End: manually power down the system to reset the program.

• Note: in heating, standby or while shutdown: the outdoor unit is forced into refrigeration operation.

(10) Refrigerant recovery

• Remove the valve cap.

• Turn the liquid stop valve and the gas stop valve with hexangular spanner until it stops. If the valve is opened with too

much force the valve will be damaged.

• Tighten the valve cap.

(8) Check vale operation

The unit is charged with R410A refrigerant. The details below should be paid attention to:

• To prevent different oils from getting into the pipe, please use the specic tool for R410A, especially for manifold gauge

and charging hose.

• To prevent the compressor oil from getting into the refrigerant cycle, please use the anti-counter-ow adapter.

Loading ...

Loading ...

Loading ...