Loading ...

Loading ...

Loading ...

11

Installation instruction

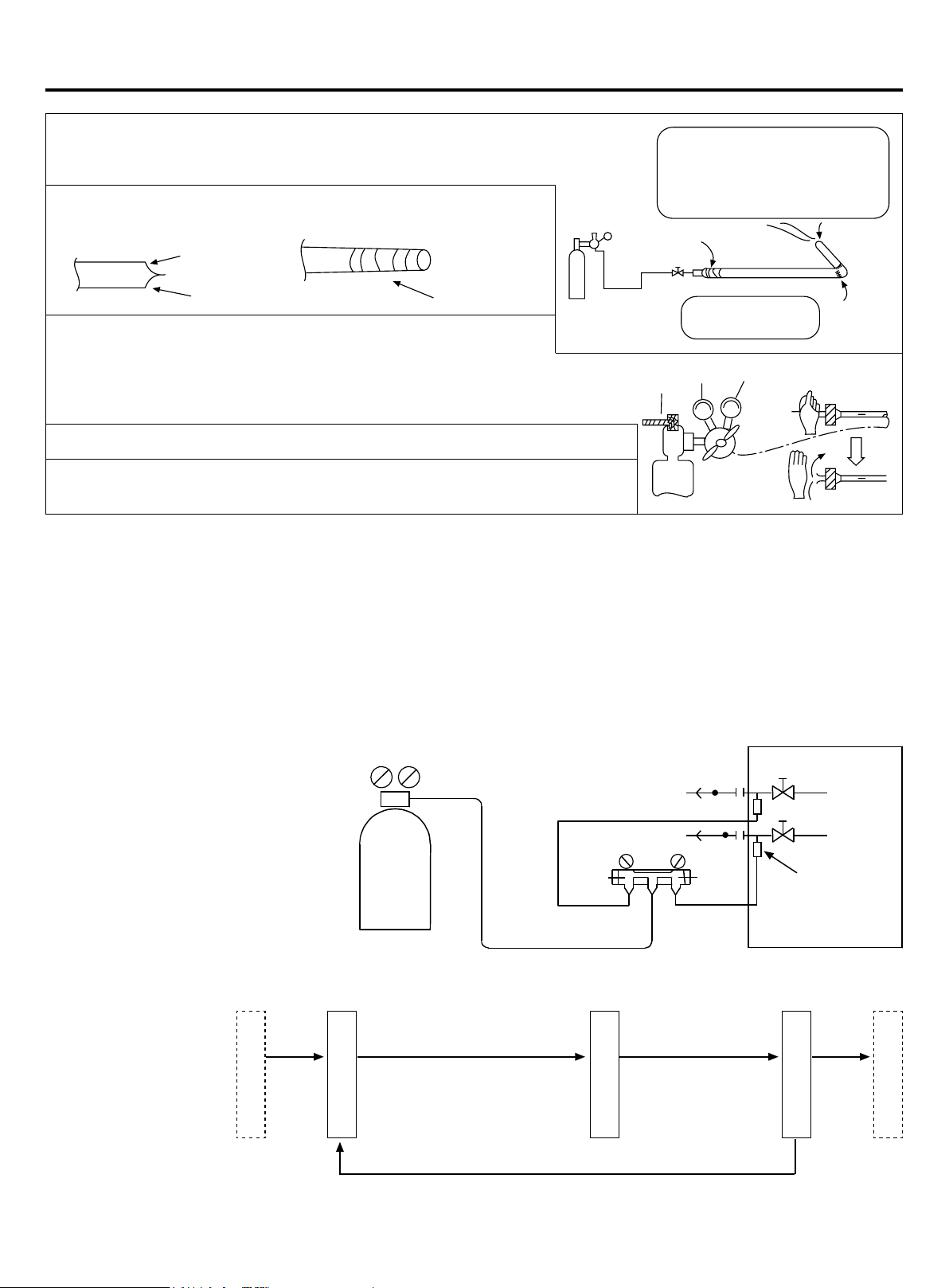

• Protect the pipe ends from getting water and other impurities into

the pipes (from welding, led or being sealed with adhesive tape).

• The refrigerant pipe should be clean. The nitrogen should ow at

pressure around 29PSI(0.2Mpa) and when charging the nitrogen,

stop up the end of the pipe by hand to increase the pressure in the

pipe, then move your hand and stop up the other end.

• Close the valves fully when connecting the pipes.

• When welding the valve and pipes, use a wet cloth to cool down the valve and

pipes.

Seal the pipe end with

adhesive tape or the stopper

to increase the resistance, ll

up the pipe with nitrogen.

Only nitrogen gas

can be used

Brazing

<N2>

Taping

Adhesive tape

Flat

Brazing

1st side

Hand

2nd side

Source valve

29PSI

(0.2MPa)

• Weld the pipe while charging with nitrogen or it will cause impurities (including

a lm of oxidation) to clog the capillary and the expansion valve which may lead

to deadly accidents.

1. The outdoor unit has been tested for leakages from the factory. After connecting the distributing pipe, test for leakages

from the outdoor check valve and the indoor pipe. While testing, the valves should be close.

2. Refer to the below gure to charge nitrogen into the unit to test. Never use chlorine, oxygen, ammable gas for the

leakage test. Apply pressure on both the gas pipe and the liquid pipe.

3. Apply the pressure step by step to the target pressure.

a. Pressurize to 72.5PSI(0.5MPa) for more than 5 minutes, check if pressure goes down.

b. Pressurize to 217.5PSI(1.5MPa) for more than 5 minutes, check if pressure goes down.

c. Pressurize to the target pressure 580PSI(4.0MPa), record the temp. and the pressure.

d. Leave it at 4.0MPa for 1 day or more, if the pressure does not go down, the test is complete.

Note that when the temp. changes

by 1degree, pressure will change

1.45PSI(0.01MPa). Correct

the pressure as needed.

e. After performing a~d, if the pressure

goes down, there is leakage. Check

any brazed and ared connections

using soapy water. Fix the leakage and

perform test again.

4. After the leakage test evacuate the

system.

Nitrogen

Hi handle

Gauge manifold

Hi

To indoor

Check valve

Gas pipe

Gas pipe

Check hole

Outdoor

Lo

Lo handle

(6) Leakage test

Leakage test passed

leave it for over 1

hour, vacuum

gauge does not arise.

after reaching -14.645PSI

(101KPa) or less (below

-755mmHg), let the vacuum

pump run continuously for 1

hour or more.

Charge refrigerant

Evacuation begins

Check vacuum

Evacuation ends

if vacuum needle rises, it shows there is water or leakage in the

system, please correct the problem and then evacuate again.

Evacute at the liquid service valve and both sides of the gas service valve.

Operation procedure:

(7) Evacuation

Loading ...

Loading ...

Loading ...