Loading ...

Loading ...

Loading ...

©2017 Pinnacle Climate Technologies 9 Vented Gas Log Appliance User’s Manual

Installation (cont.)

BEFORE INSTALLING THE APPLIANCE

• Turn o the gas supply to the replace or rebox.

• Clean the replace oor and chimney, seal any ash, and

clean out the doors to protect from any down drafts.

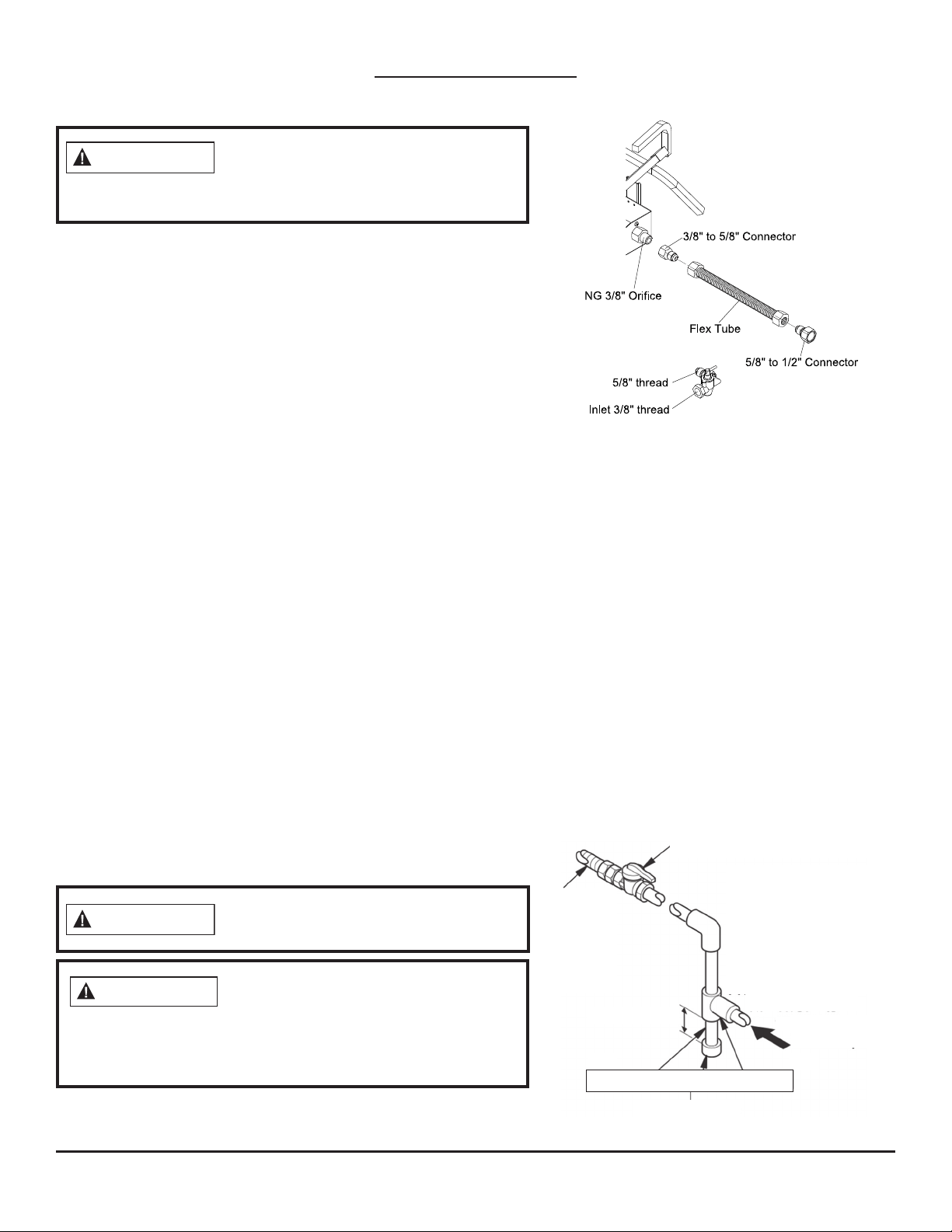

INSTALLATION AND GAS CONNECTION* (See Fig. 6 & 7)

1. Place the burner pan assembly in the center of the replace

oor. The front of the pan must face forward.

2. Install the 3/8" orice tting onto the burner inlet tting using

thread sealant on male threads of the burner inlet tting.

3. If the gas supply has an equipment shuto valve within

reach of lighting the log set, then thread the 1/2" connector

to the shuto valve. Use thread sealant.

4. If the gas supply does not have an equipment shuto valve

within reach, a manual gas valve is provided. Connect the

manual gas valve to gas supply pipe. Use thread sealant.

5. Attach the gas ex tube to the gas supply. Shape the tube

to attach to the orice tting.

CONNECTION TO GAS SUPPLY

Installation Items Needed:

• piping (check local codes)

• sealant (resistant to natural gas)

• equipment shuto valve

• test gauge connection

Installation must include an equipment shuto valve, union,

and plugged 1/8" NPT tap. Locate the NPT tap within reach

for test gauge hook up. The NPT tap must be upstream from

the appliance (see Figure 7).

* In compliance with ANS Z21.60•CSA2.26 and National Fuel Gas Code, Section 6.

Before installing the appliance, have the

fireplace and chimney professionally cleaned

to remove any soot, creosote, ashes, or other

obstructions. Perform this cleaning annually after installation.

WARNING

A qualified service person must connect the

appliance to gas supply. Follow all local codes.

WARNING

Only use a new black iron or steel pipe.

Internally-tinned copper tubing may be

used in certain areas. Check local codes. To allow proper gas

volume to the appliance, use a pipe of 1/2" diameter or greater.

Loss of pressure occurs if the pipe is too small.

CAUTION

• sediment trap

• tee joint

• pipe wrench

• adjustable (crescent)

wrench or pliers

IMPORTANT: Install the equipment shuto valve

in an accessible location. The equipment shuto

valve is used for turning on or shutting o the

gas to the appliance.

Lightly apply pipe joint sealant to the male

threads. This prevents excess sealant from going

into the pipe. A clogged burner injector may

result from excess sealant in the pipe.

Install the sediment trap in the supply line (see

Fig. 7). Locate the sediment trap so it can easily

be cleaned and where trapped material is unlike-

ly to freeze. A sediment trap traps moisture and

contaminants, keeping them from going into the

appliance controls. The appliance may not oper-

ate correctly if the sediment trap is not installed

or is installed incorrectly.

7''

(5.5''

Equipment Shuto Valve With

1/8" NPT Tap

Approved

Flexible

Gas Line

or 1/2"

Black Pipe

3" Minimum

Sediment Trap

Propane/LP

From External

Regulator (11"

W.C. to 14" W.C

Pressure)

Natural

From Gas Meter

(7" W.C.** to

10.5" W.C.

Pressure)

Fig. 6

Fig. 7

Pipe Nipple Cap Tee Joint

Loading ...

Loading ...

Loading ...