Loading ...

Loading ...

Loading ...

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

68 | DUCTED

Ceiling-Concealed Ducted System Engineering Manual

REFRIGERANT PIPING DESIGN

Refrigerant Piping System Layout

Piping can be installed

in one of four different

layouts.

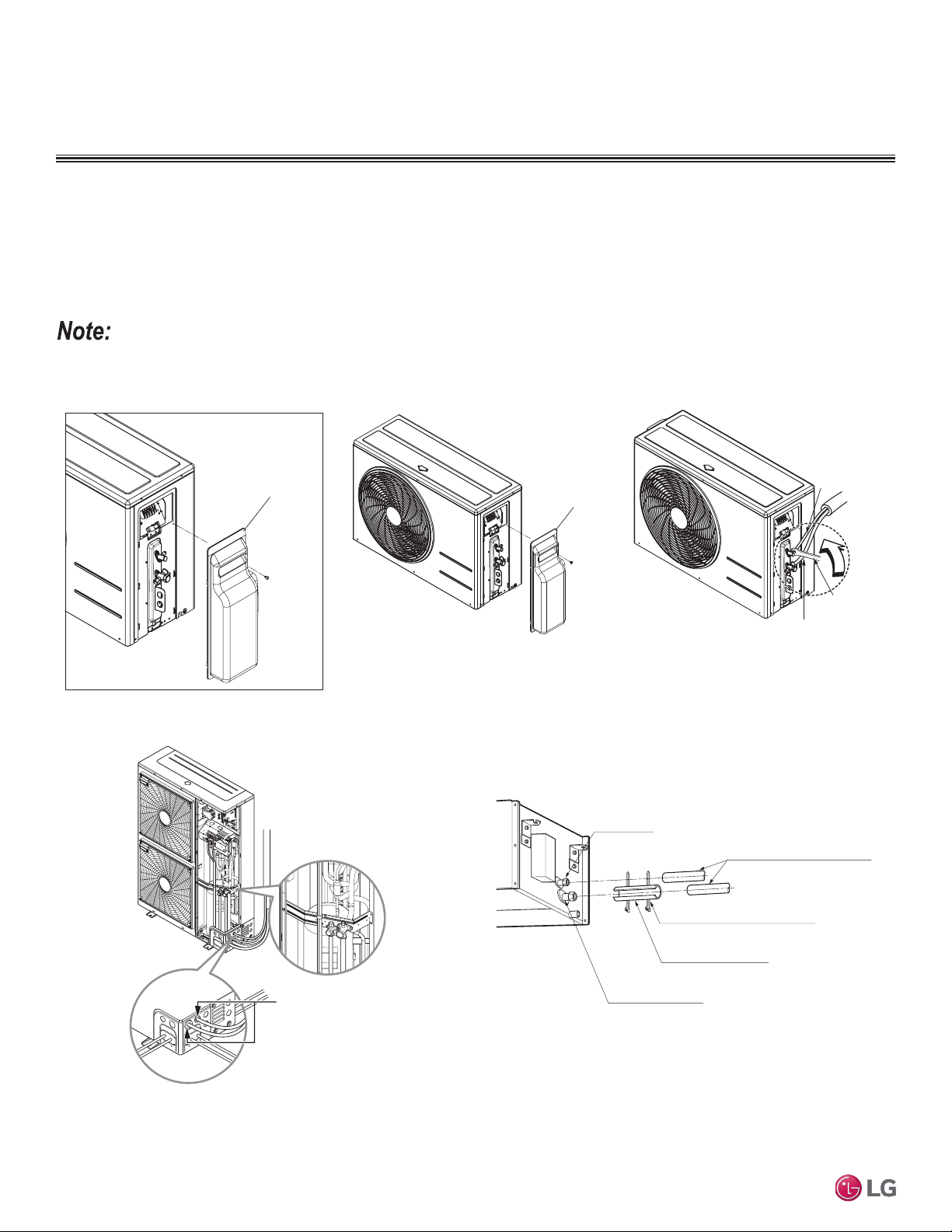

Single Zone Ducted Outdoor Unit Connections

1. Remove the connection cover from the unit by loosening the screws.

2. Align the center of the refrigerant pipe and corresponding connection.

3. Place a couple of drops of refrigerant oil on the opening rim of the flare before assembling. Ensure you do not add any contaminants.

Tighten the flare nut initially by hand.

4. Finish tightening the flare nut with a torque wrench until the wrench clicks. See page 69 for torque information.

Figure 54: Removing the Refrigerant Piping

Connection Cover (LUU097HV, LUU127HV).

Figure 55: Removing the Refrigerant Piping

Connection Cover (LUU247HV).

Figure 56: LUU097HV, LUU127HV, LUU247HV

Refrigerant Piping Connections.

Outdoor unit

Gas side piping

(Bigger diameter)

Liquid side piping

(Smaller diameter)

Torque wrench

Connection cover

When tightening the are nut with a torque wrench, ensure the direction for tightening follows the arrow on the wrench.

Tubing cover

Figure 58: LUU367HV Refrigerant Piping Connections.

Figure 57: Ceiling-Concealed Ducted Refrigerant Piping Connections.

Liquid Piping

Connection

Insulation for Refrigerant Piping

(Field-Supplied)

Vapor Piping Connection

Insulation

(Field-Supplied)

Clamp for Insulation

(Field-Supplied)

Ensure no gaps are present.

Overlap the Insulation at the

Connection

Insulation for Refrigerant Piping

(Field-Supplied)

Insulation for Field-Installed Piping

(Field-Supplied)

Single Zone Ducted Indoor Unit

Connections

Loading ...

Loading ...

Loading ...