Loading ...

Loading ...

Loading ...

15

Figure 12

ASSEMBLY

ADJUSTMENTS

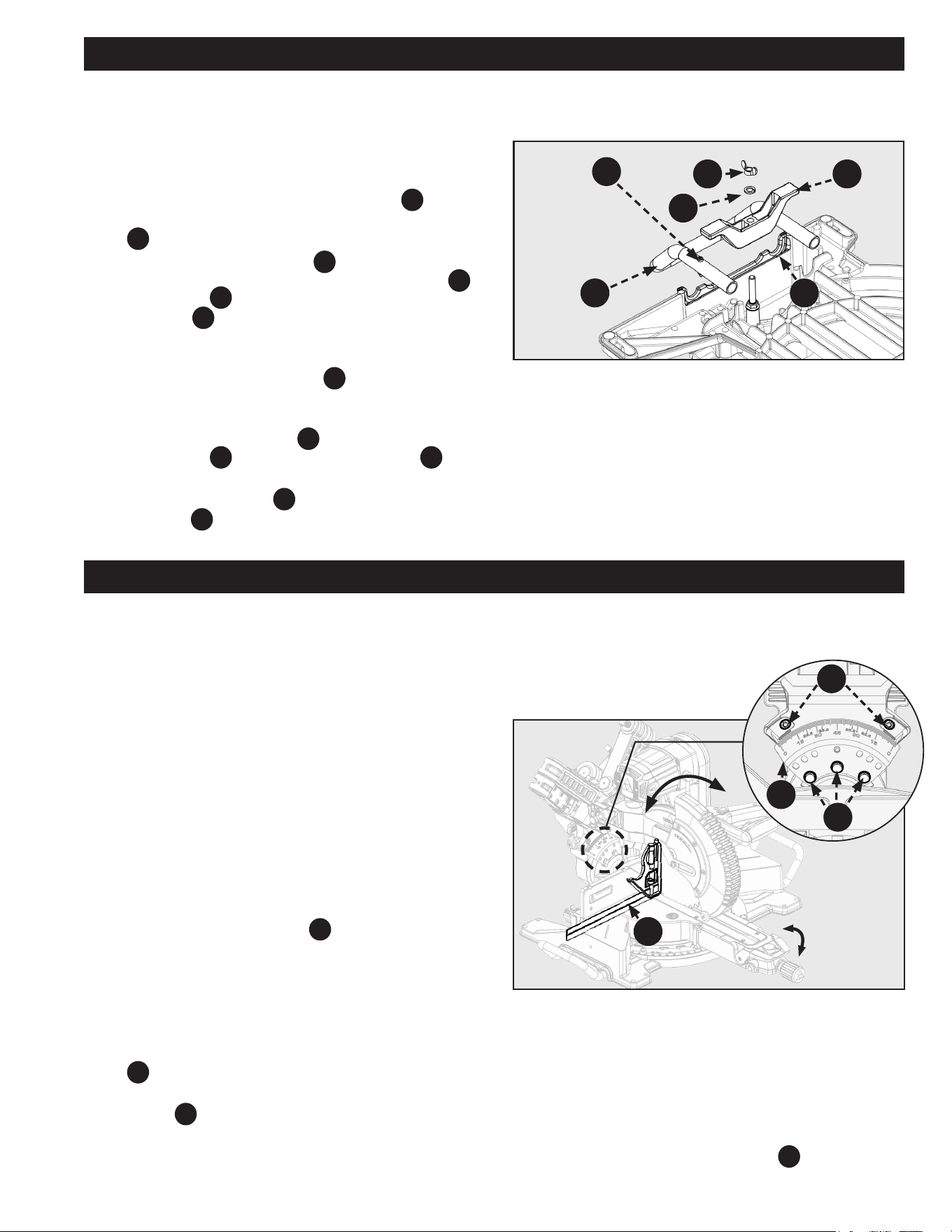

BEVEL ALIGNMENT

Your saw is calibrated at the factory to cut true. Over time the

saw’s calibration may drift and will need to be re-calibrated.

See Figure 12.

1. Unplug the saw.

2. Lower the saw head all the way down to the transport

position and engage the saw head lock pin to hold it

in place. Push the saw head into the fully retracted

position and engage the slide prevention lock to hold it

in place.

3. Set the miter position to 0° and engage the miter lock

knob so the table will not move.

4. Set the bevel position to 0°. Engage the bevel latch

lever, so the detent pin locks into the bevel scale.

5. Place a combination square

A

against the table and

the face of the saw blade.

NOTE: Make sure the square contacts the flat part of the

blade and not the teeth.

6. Rotate the blade by hand and check the blade-to-table

alignment at several points. If the blade face is not ush

with the square you will need to adjust the bevel scale

F6

.

7. Using a 10mm combination wrench loosen the three

screws

C

and adjust the bevel scale position. Set so

the table and blade are ush against the combination

square. Make sure the bevel lock/unlock handle is not

locked, so the scale may be adjusted.

LOCK

UNLOCK

A

F6

D

C

Figure 11

INSTALLING WORKPIECE

SUPPORT EXTENSIONS

See Figure 11.

To assemble the support extensions:

1. Insert one of the Support Extensions

PC5

to the

underside of the Base at the cast-in Handle cut-outs

B

.

2. Make sure Support Extension

PC5

is ush with the Base

and inserted into the rounded slots of the cut-outs

B

.

The Rivets

C

are used to prevent the Support

Extension

PC5

from sliding out of the Base during use.

These Rivets should be positioned on the inside of the

Base.

3. Place the Extension Clamp

PC6

onto the Support

Extension and the screw that is pre-attached to the

Base.

4. Once the Extension Clamp

PC6

is in place, put the Split

Lock Washer

PC7

rst and screw the Wing Nut

PC8

onto

the screw.

5. Tighten the Wing Nut

PC8

to fully secure the Support

Extension PC5 .

6. Repeat on the other side.

PC6

PC7

PC5

C

PC8

B

8. Re-tighten the three screws and re-check the blade-to-

table alignment.

NOTE: After squaring adjustments have been made, it may be

necessary to loosen the indicator screws

D

and reset them

to zero.

Loading ...

Loading ...

Loading ...