Loading ...

Loading ...

Loading ...

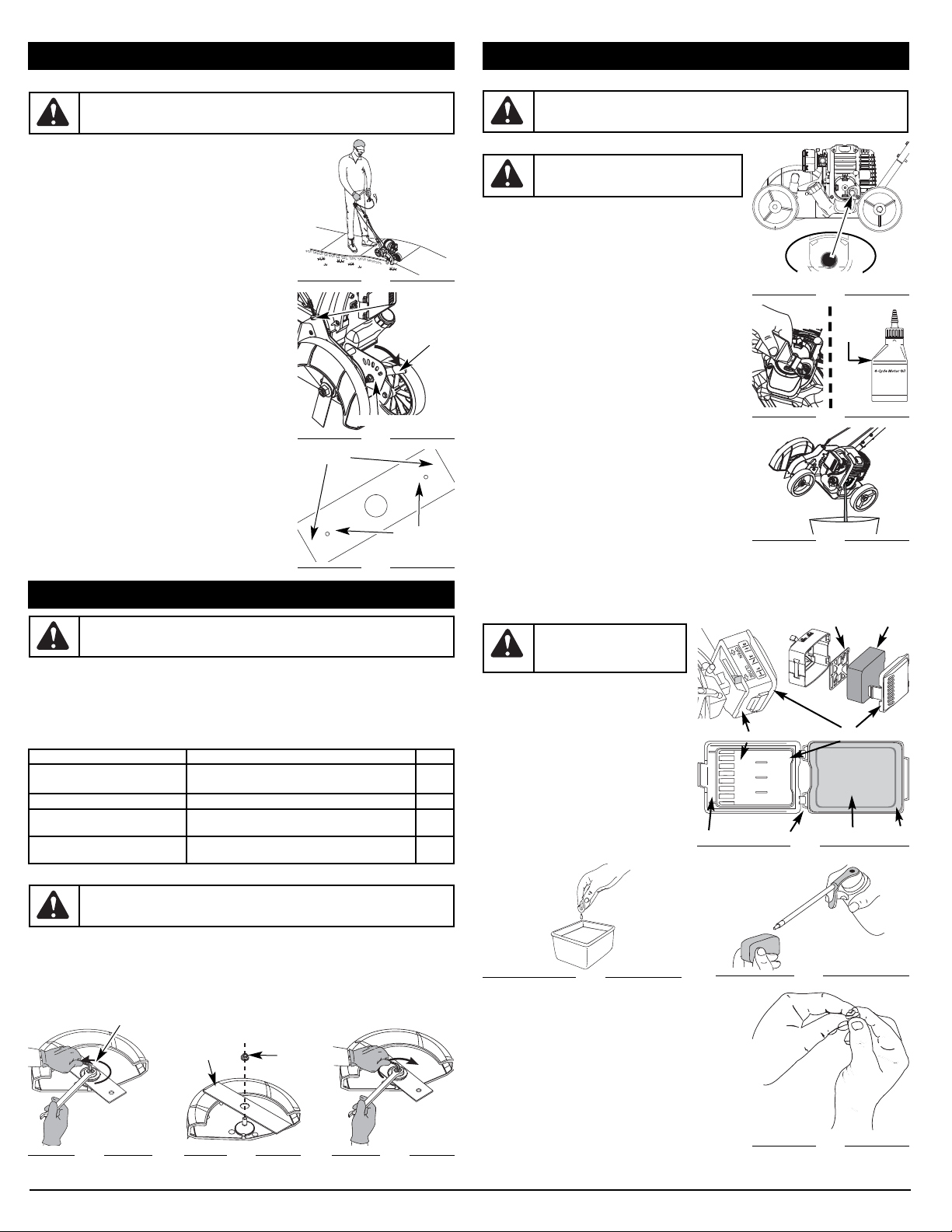

NOTE: Make sure that the blade stays flat and centered against the output shaft throughout installation.

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper oil level in

the crankcase cannot be overemphasized. Check oil before each

use:

1. Stop the engine and allow oil to drain into the crankcase.

2. Place the unit on a level surface to get a proper oil level

reading (Fig. 20).

3. Keep dirt, grass clippings and other debris out of the engine.

Clean the area around the oil fill plug before removing it.

4. Remove the oil fill plug.

5. Look into the oil fill hole, use a flashlight if needed. The oil

should be just touching the inner most thread (Fig. 20).

6. If the oil level is not touching the inner most thread on the oil

fill hole, add a small amount of oil to the oil fill hole and

recheck (Fig. 21). Repeat this procedure until the oil level

reaches the inner most thread on the oil fill hole.

NOTE: Do not overfill the unit.

NOTE: Make sure the O-ring is in place on the oil fill plug when

checking and changing the oil (Fig. 8).

CHANGING THE OIL

For a new engine, change the oil after the first 10 hours of

operation. Change the oil while the engine is still warm. The oil will

flow freely and carry away more impurities.

1. Unplug spark plug boot to prevent accidental starting.

2. Remove the oil fill plug.

3. Pour the oil out of the oil fill hole and into a container by

tipping the unit to a vertical position (Fig. 22). Allow ample

time for complete drainage.

4. Wipe up any oil residue on the unit and clean up any oil that

may have spilled. Dispose of the oil according to Federal,

State and local regulations.

5. Refill the crankcase with 3.04 fluid ounce (90 ml or 3/8 cup) of

SAE 30 SF, SG, SH oil.

NOTE: Use the bottle and spout saved from initial use to measure

the correct amount of oil. The top of the label on the bottle measures approximately 3.04 ounces

(90 ml) (Fig. 21). Check the level, See Checking the Oil Level. If the level is low, add a small

amount of oil and recheck. Do not overfill (Fig. 20).

6. Replace the oil fill plug.

7. Reconnect the spark plug boot.

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Clean and re-oil the air filter every 10 hours of

operation. It is an important item to maintain. Failure

to maintain your air filter properly can result in poor

performance or can cause permanent damage to

your engine.

1. Open the air filter cover. Push the tab on the left

side of the cover in, swing the air filter cover out

and off the air filter housing (Fig. 23).

2. Remove the air filter and the screen that sits

behind it (Fig. 23).

3. Wash the filter in detergent and water (Fig. 24).

Rinse the filter thoroughly and allow it to dry.

4. Apply enough clean SAE 30 motor oil to lightly

coat the filter (Fig. 25).

5. Squeeze the filter to spread and remove excess

oil (Fig. 26).

6. Replace the filter (Fig. 23).

NOTE: If the unit is operated without the air filter, you will VOID

the warranty.

7. Reinstall the air filter cover. Position the tabs on the sides of

the air filter cover onto the slots at the top of the back plate

(Fig. 23).

8. Push the cover in until the tab on the air filter backplate snaps

into place in the slot on the air filter cover (Fig. 23).

5

HOLDING THE UNIT

Before operating the unit, stand in the operating position (Fig. 14).

Check for the following:

• The operator is wearing eye protection and proper clothing.

• Both hands are holding the handle bar firmly.

• The edger wheel adjusted for proper cut depth as shown in

Figure 15 and edger positioned as shown in Figure 14.

ADJUSTING EDGER CUTTING DEPTH

1. Grasp the depth adjustment lever located beside the front

wheel (Fig 15).

2. To raise the cutting blade, move the lever toward the front of

the wheel bracket (Fig. 15). Lowering the wheel decreases the

cutting depth.

3. To lower the cutting blade, move the lever toward the rear of

the wheel bracket. Raising the wheel increases the cutting

depth.

TIPS FOR BEST EDGING RESULTS

• Do not force the edger. Edge the first time at a lesser

depth,(No more than 1/2” depth cut per pass), then do the area

again with a deeper setting.

• Walk the edger at a slow, even pace.

• Check the blade condition. As it wears it becomes smaller,

thus reducing the cutting depth performance. Replace with a

new blade when the blade has worn to the blade’s wear limit

holes (Fig. 16).

ADJUST BELT TENSION

If blade fails to turn when the bail is pulled, then:

1. Locate small thumb wheel on top of the belt housing (Fig. 15).

2. Turn the wheel clockwise 1 revolution to increase the tension

on the belt.

3. Try pulling the bail and see if the blade turns. If not, repeat

step 2 until the blade turns.

WARNING:

Always wear eye, hearing, foot and body protection to reduce the risk of

injury when operating this unit.

Fig. 15

Thumb

Wheel

Wheel Bracket

Depth

Adjustment

Lever

Fig. 16

Blade Edges

Wear Limit

Holes

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These procedures

should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these

procedures take your unit to a Troy-Bilt or other qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be

performed by a Troy-Bilt or other qualified service dealer.

WARNING:

To prevent serious injury, never perform maintenance or repairs with unit

running. Always service and repair a cool unit. Disconnect the spark plug wire to ensure

that the unit cannot start.

OPERATING INSTRUCTIONS

Fig. 14

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting engine

Fill fuel tank with fresh fuel

Check oil

p. 4

p. 5

Every 10 hours Clean and re-oil air filter p. 5

1st change at 10 hours

Every 25 hours after

Change oil

Clean spark arrestor

p. 5

p. 6

10 hours on new engine

Every 25 hours

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 6

p. 6

MAINTENANCE AND REPAIR INSTRUCTIONS

BLADE REPLACEMENT

1. Place the 5/16” Allen wrench in the spindle hole (Fig. 17).

2. While holding the Allen wrench in place, loosen the nut with a 15/16” wrench by turning it

counterclockwise (Fig. 17).

3. Re move the nut and blade. Keep the nut for new blade installation.

4. Install the new blade and nut (Fig. 18).

5. While holding the Allen wrench in the spindle hole, tighten the nut by turning the wrench clockwise

until tight (Fig. 19).

WARNING:

To avoid serious personal injury, always wear gloves while han dling,

removing or in stall ing the blade.

Fig. 17

Loosen

Spindle Hole

Fig. 18

Nut

Edger Blade

Fig. 19

Tighten

WARNING:

Verify the blade is flat against the output shaft after the nut is tightened. If

the blade is off-cen ter, the unit will be dam aged by vibration, and the blade may fly off,

which can cause serious personal in ju ry.

Fig. 20

Max Oil Fill Line

Fig. 22

CAUTION:

Wear gloves to prevent injury

when handling unit.

Fig. 21

Fill Level

WARNING:

To avoid serious

personal injury, always turn the unit

off and allow it to cool before you

clean or service it.

Fig. 23

Screen

Air Filter

Air Filter

Hooks

Tab

Air Filter Cover

Air Filter Housing

Slot

Fig. 24

Fig. 25

Fig. 26

Loading ...

Loading ...

Loading ...