Loading ...

Loading ...

Loading ...

16 www.senixtools.com

MAINTENANCE

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

NOTICE: Users are not allowed to set the carburetor or

ignition. If further assistance is required, take the unit to

a qualified service dealer.

WARNING:

To avoid serious injury, always stop the engine and

allow it to cool before cleaning or maintaining the unit.

Never perform cleaning or maintenance while the unit is

running. Disconnect the spark plug wire to prevent the

unit from starting accidentally.

WARNING:

Wear protective clothing and observe all safety instruc-

tions to prevent serious injury.

CLEANING

Use a small brush to clean the outside of the unit. Do

not use strong detergents. Household cleaners that

contain aromatic oils such as pine and lemon, and sol-

vents such as kerosene, can damage plastic. Wipe off

any moisture with a soft cloth.

Correct and regular cleaning is not only important for

the safe use of this product, but also extends its life

span.

LUBRICATION

For a long lifespan, make sure that the cutting blades

are cleaned and lubricated at regular intervals in order

to ensure the best possible performance. Routinely ap-

ply a thin film of lubricating oil.

REPLACING THE BLADES

WARNING:

To avoid serious injury, always stop the engine and

allow it to cool before replacing the blades.

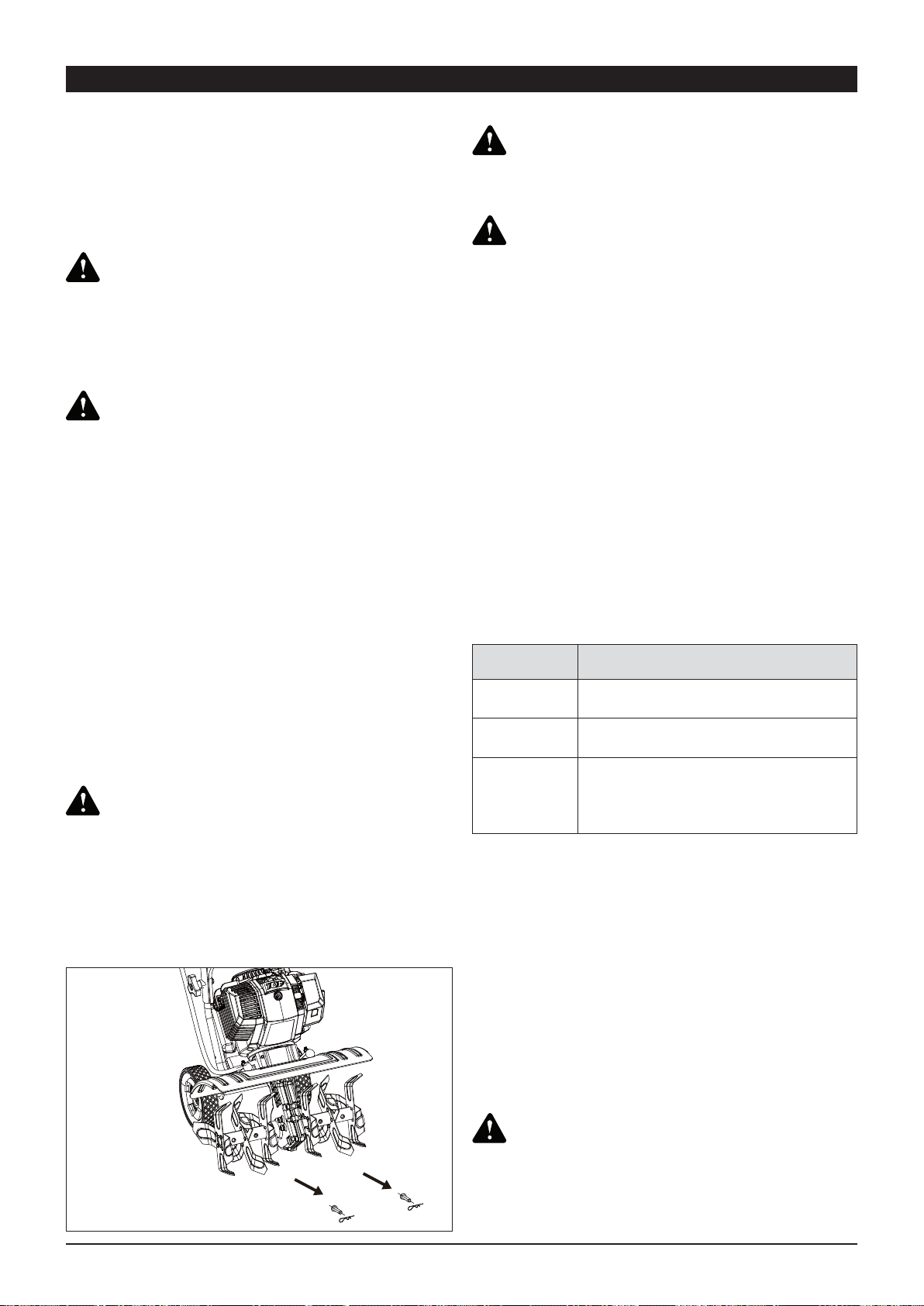

To replace the blades, take off the pin.

Take off the broken blades and replace the new blades

according to the original position (Fig. 13).

Re-insert the pin to secure the blades.

Fig. 13

MAINTENANCE SCHEDULE

WARNING:

When the engine idles, user should check the cutting

attachment stops while turning routinely.

WARNING:

To prevent any danger or defects, user should check

and maintain every part of the machine before use and

after dropping or other impacts.

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should

also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require

special tools or skills. If you are unsure about these pro-

cedures, take the unit to a qualified service dealer.

NOTE: Maintenance, replacement, or repair of the

emission control devices and system may be performed

by a qualified service dealer.

NOTE:

Please read the California/EPA statement that

came with the unit for a complete listing of terms and

coverage for the emissions control devices, such as the

spark arrestor, muffler, carburetor, etc.

FREQUENCY

MAINTENANCE REQUIRED

Every 10 hours

Ь Clean the air filter.

Refer to Maintaining the Air Filter.

Every 20 hours

ЬChange the oil. Refer to Changing the Oil.

• Replace the oil after the first 5 hours.

Every 30 hours

ЬHave the rocker arm clearance checked by a

qualified service dealer.

• Check the spark plug condition and gap.

Refer to Maintaining the Spark Plug.

NOTE: If the engine frequently work under dusty or

other severe circumstances, increase the cleaning fre-

quency.

REMARKS

• The maintenance interval is only a recommendation

for machines in ordinary operating condition.

• If there are any abnormal signs from the machine,

please do the proper inspection and maintenance im-

mediately.

• All other repairs or maintenance should be done by a

qualified service center

CHECKING THE OIL LEVEL

WARNING:

Check the oil level before each use. The importance of

maintaining the proper oil level cannot be overempha-

sized.

Loading ...

Loading ...

Loading ...