Loading ...

Loading ...

Loading ...

About the water softener system.

Breaking a Salt Bridge

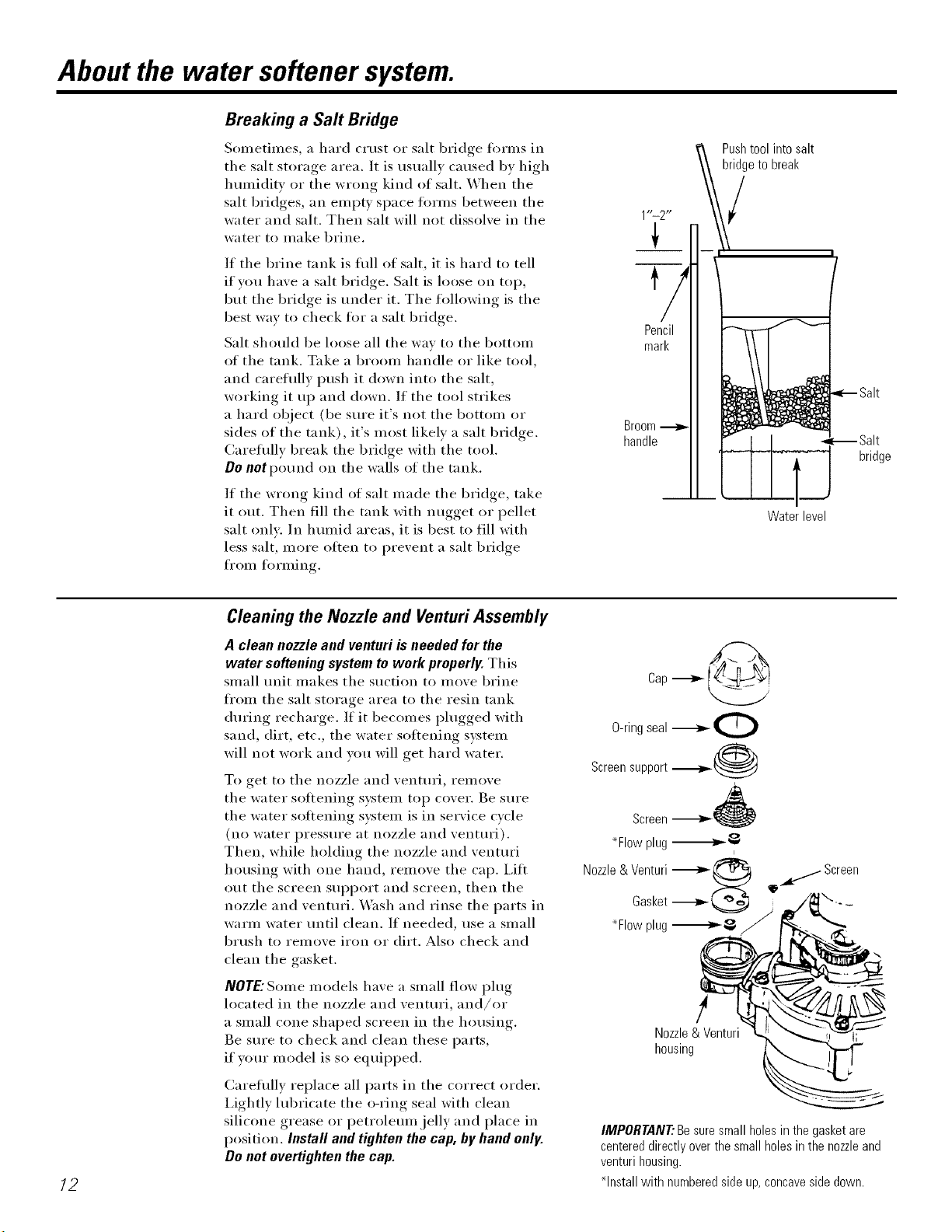

Sometimes, a hard crest or salt bridge forn_s in

the salt storage area. It is usually caused by high

humidity or the wrong kind of salt. When the

salt bridges, an empty space torms between tile

water and salt. Then salt will not dissolve in the

water to make brine.

If tile brine tank is full of salt, it is hard to tell

if wm have a salt bridge. Salt is loose on top,

but the bridge is under it. The following is the

best way to check tot a salt bridge.

Salt should be loose all the way to the bottom

of tile tank. Take a broom handle or like tool,

and carefully push it down into the salt,

working it up and down. If tile tool strikes

a hard object (be s/tt'e it's not tile bottom or

sides of the tank), it's most likely a salt bridge.

Carefltllv break the bridge with the tool.

Do notpound on tile walls of tile tank.

If the wrong kind of salt made the bridge, take

it out. Then fill the tank with nugget or pellet

salt only: In lmmid areas, it is best to fill with

less salt, inore often to prevent a salt bridge

fl'om limning.

Pencil

mark

Broom

handle

Pushtool intosalt

bridgeto break

/

Waterlevel

bridge

12

Cleaning the Nozzle and VenturiAssembly

A clean nozzle and venturi is needed for the

water softening system to work properly. This

small trait makes tile suction to move brine

fl'om tile salt storage area to tile resin tank

dm'ing recharge. If it becomes plugged with

sand, dirt, etc., tile water softening s):stem

will not work and you will get hard water.

To get to tile nozzle and venturi, remove

the water softening system top covet'. Be sure

the water softening system is in service cycle

(no water pressure at nozzle and venturi).

Then, while holding the nozzle and venmri

housing with one hand, remove tile cap. i,ifl

out tile screen sui)port and screen, then tile

nozzle and venturi. Wash and rinse tile parts in

warm water tmtil clean. If needed, use a small

brush to remove iron or dirt. Also check and

clean the gasket.

NOTE: Some models have a small flow plug

located in tile nozzle and venmri, and/or

a small cone shaped screen in the housing.

Be sure to check and clean these parts,

if vo m" model is so eq uiI)ped.

Carefltlly replace all parts in tile correct order.

I,ightly lubricate the o-ring seal with clean

silicone grease or petroleum.jelly and place in

position. Install and tighten the cap, by hand only.

Do not overtighten the cap.

Cap

9/Screen

Nozzle& Venturi

housing

IMPORTANT"Besuresmallholesin the gasketare

centereddirectlyoverthe smallholesin the nozzleand

venturihousing.

*Install with numberedsideup,concavesidedown.

Loading ...

Loading ...

Loading ...