Loading ...

Loading ...

Loading ...

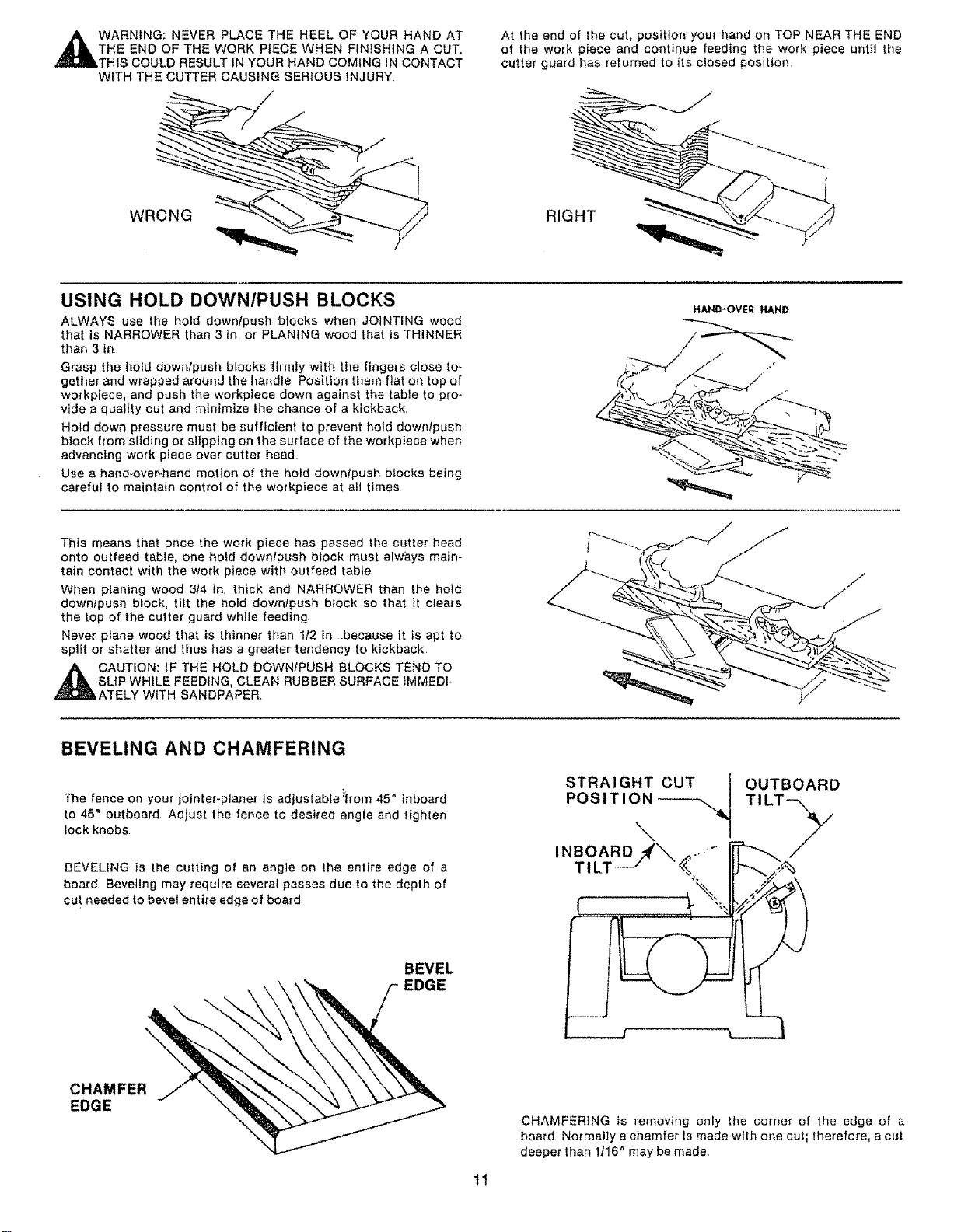

,_WARNING: NEVER PLACE THE HEEL OF YOUR HAND AT

THE END OF THE WORK PIECE WHEN FINISHING A CUT.

THIS COULD RESULT tN YOUR HAND COMING IN CONTACT

WITH THE CUTTER CAUSING SERIOUS tNJURY.

At the end of the cut, position your hand on TOP NEAR THE END

of the work piece and continue feeding the work piece until the

cutter guard has returned to its closed position

RIGHT

USING HOLD DOWNIPUSH BLOCKS

ALWAYS use the hold down/push blocks when JO_NTING wood

that is NARROWER than 3 in or PLANING wood that is THINNER

than 3 in

Grasp the hold downlpush btocks firmly with the fingers close to..

gether and wrapped around the handle Position them fiat on top of

workpiece, and push the workpiece down against the table to pro-

vide a quality cut and minimize the chance of a kickback.

Hold down pressure must be sufficient to prevent hold down/push

block from sliding or slipping on the surface of the workpiece when

advancing work piece over cutter head

Use a handoover,.hand motion of the hold downlpush blocks being

careful to maintain control of the workpiece at all times

HAND'OVER HAND

This means that once the work piece has passed the cutter head

onto outfeed table, one hold downlpush block must always main °

tain contact with the work piece with outfeed table

When planing wood 3t4 in. thick and NARROWER than the hold

downlpush btock, tilt the hold downlpush block so that it clears

the top of the cutter guard while feeding.

Never plane wood that is thinner than 1/2 in .because it is apt to

split or shatter and thus has a greater tendency to kickback

,_CAUTION: IF THE HOLD DOWNfPUSH BLOCKS TEND TO

SLIP WHILE FEEDING, CLEAN RUBBER SURFACE IMMEDI-

ATELY WITH SANDPAPER.

BEVELING AND CHAMFERING

The fence on your jointer-planer is adjustable_rom 45 ° inboard

to 45 ° outboard Adjust the fence to desired angle and tighten

lock knobs

BEVELING is the cutting of an angle on the entire edge of a

board Beveling may require several passes due to the depth of

cut needed to bevel entire edge of board.

OUTBOARD

BEVEL

EDGE

CHAMFER

EDGE

tl

CHAMFERING is removing only lhe corner of the edge of a

board Normally a chamfer is made with one cut; therefore, a cut

deeper than 1116" may be made

Loading ...

Loading ...

Loading ...