Loading ...

Loading ...

Loading ...

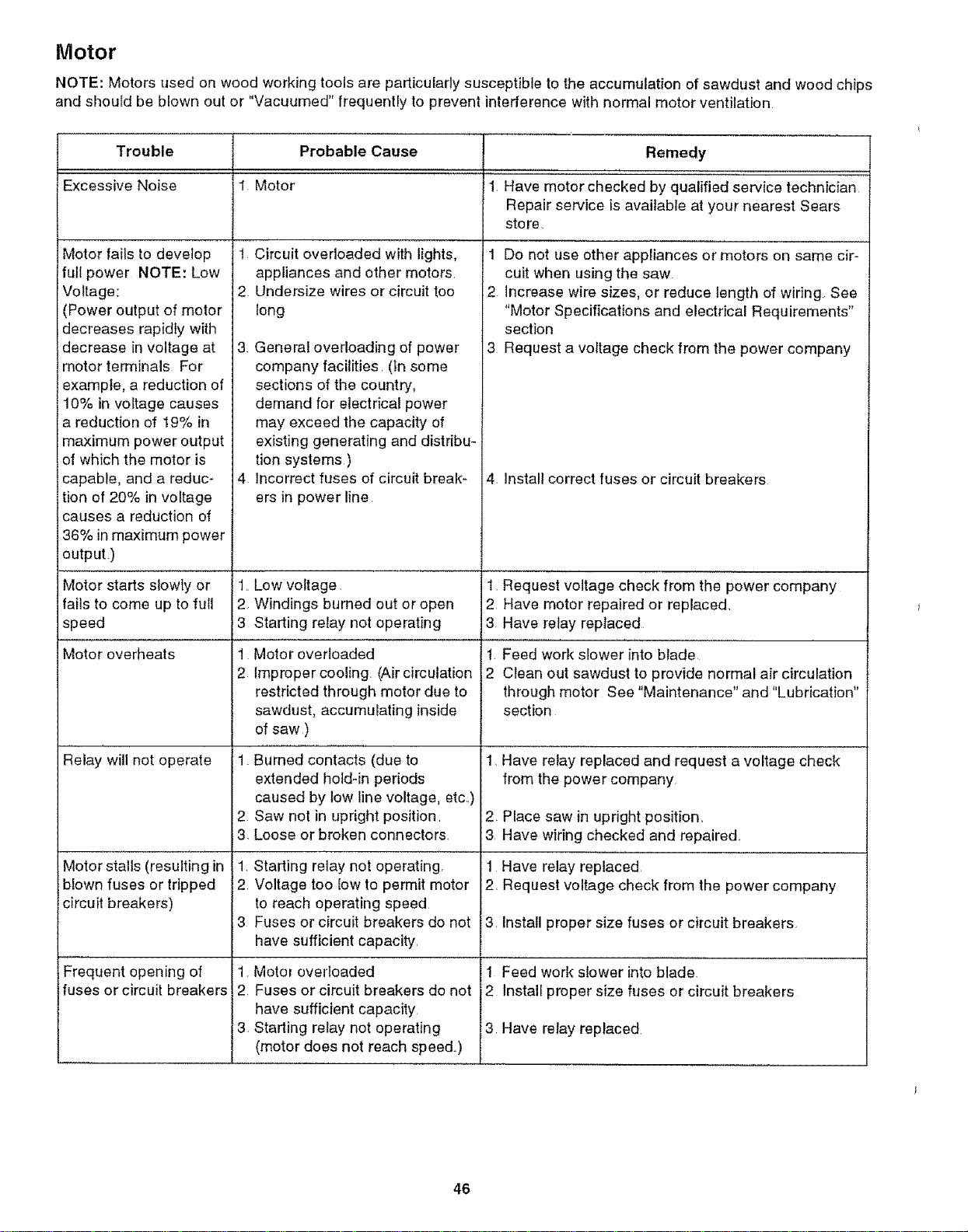

Motor

NOTE: Motors used on wood working tools are particularly susceptible to the accumulation of sawdust and wood chips

and shouId be blown out or "Vacuumed" frequently to prevent interference with normal motor ventilation

Trouble Probable Cause

FExcessive Noise 1 Motor

Motor fails to develop

full power NOTE: Low

Voltage:

(Power output of motor

decreases rapidly with

decrease in voltage at

motor terminals For

example, a reduction of

110% in voltage causes

'.a reduction of 19% in

maximum power output

of which the motor is

capable, and a reduc-

tion of 20% in voltage

causes a reduction of

36% in maximum power

output.)

Motor starts slowly or

fails to come up to full

speed

Motor overheats

Relay will not operate

Motor stalls (resulting in

blown fuses or tripped

circuit breakers)

Frequent opening of

fuses or circuit breakers

t Circuit overloaded with lights,

appliances and other motors

2 Undersize wires or circuit too

long

3. General overloading of power 3

company facilities r(in some

sections of the country,

demand for electrical power

may exceed the capacity of

existing generating and distribu-

tion systems )

4 Incorrect fuses of circuit break-

era in power line

1. Low voltage 1.

2 Windings burned out or open 2

3 Starting relay not operating 3

1 Motor overloaded 1

2 Improper cooling (Air circulation 2

restricted through motor due to

sawdust, accumulating inside

of saw )

1. Burned contacts (due to 1,

extended hold-in periods

caused by low line voltage, etc.,)

2. Saw not in upright position 2.

3. Loose or broken connectors. 3

1. Starting relay not operating, 1

2 Voltage too low to permit motor 2.

to reach operating speed

3 Fuses or circuit breakers do not i3

have sufficient capacity.

1. Motol overloaded j l

2 Fuses or circuit breakers do not 2

have sufficient capacity

3. Starting relay not operating _3

(motor does not reach speed.)

Remedy

1 Have motor checked by qualified service technician

Repair service is available at your nearest Sears

store.

1 Do not use other appliances or motors on same cir-

cuit when using the saw

2. Increase wire sizes, or reduce length of wiring. See

"Motor Specifications and electrical Requirements"

section

Request a voitage check from the power company

4. Install correct fuses or circuit breakers

Request voltage check from the power company

Have motor repaired or replaced.

Have relay reptaced

Feed work slower into blade

Clean out sawdust to provide normal air circulation

through motor See "Maintenance" and "Lubrication"

section

Have relay replaced and request a voltage check

from the power company

Place saw in upright position.

Have wiring checked and repaired.

Have relay replaced

Request voltage check from the power company

Install proper size fuses or circuit breakers.

Feed work slower into blade

Install proper size fuses or circuit breakers

Have relay replaced.

46

Loading ...

Loading ...

Loading ...