Loading ...

Loading ...

Loading ...

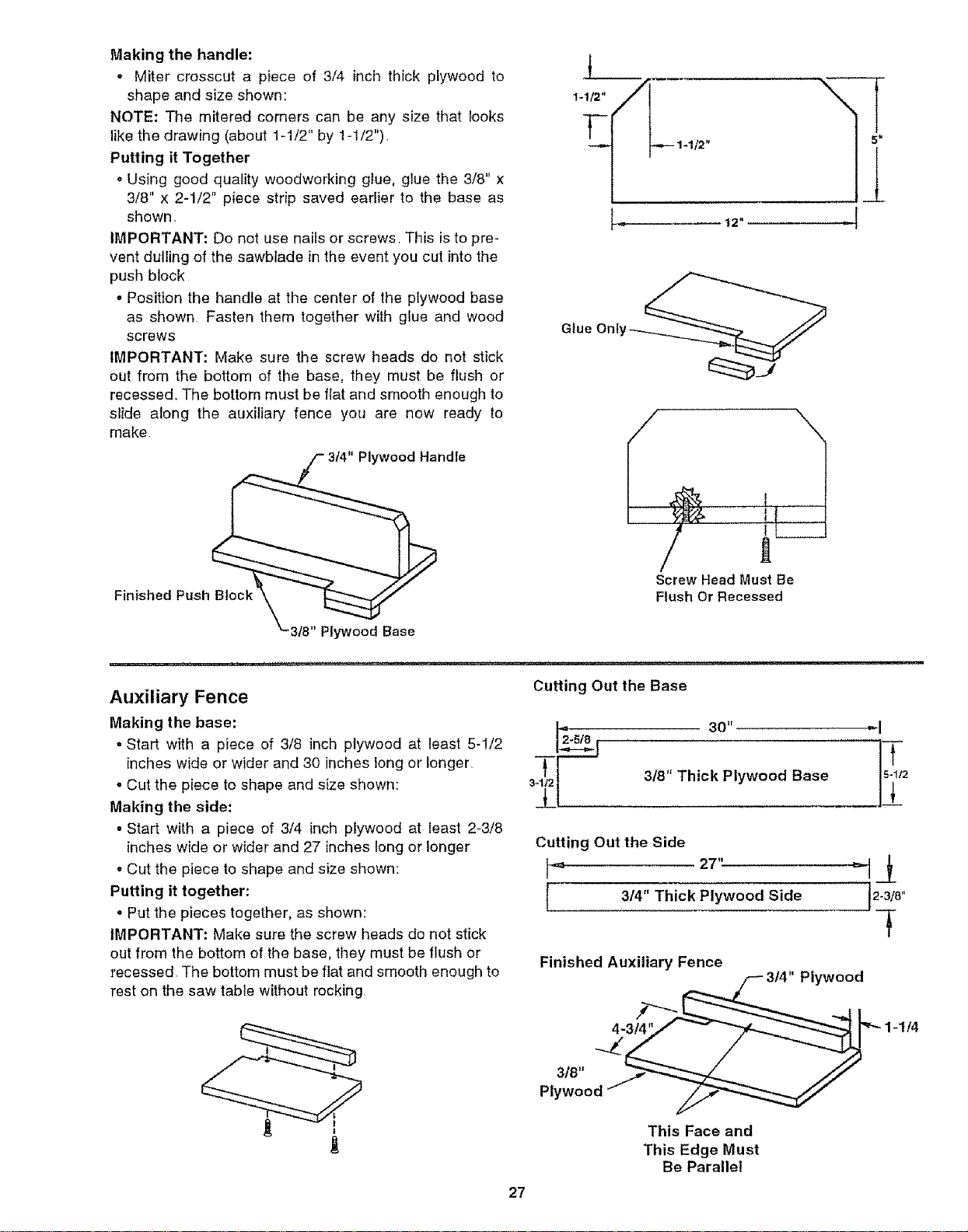

Making the handle:

- Miter crosscut a piece of 3/4 inch thick plywood to

shape and size shown:

NOTE: The mitered comers can be any size that looks

like the drawing (about 1-1/2" by 1-1/2"),

Putting it Together

• Using good quality woodworking glue, glue the 3/8" x

3/8" × 2-1/2" piece strip saved earlier to the base as

shown,

IMPORTANT: Do not use nails or screws, This isto pre-

vent dulling of the sawbtade in the event you cut intothe

push block

o Position the handle at the center of the plywood base

as shown Fasten them together with glue and wood

screws

IMPORTANT: Make sure the screw heads do not stick

out from the bottom of the base, they must be flush or

recessed,, The bottom must be flat and smooth enough to

slide along the auxiliary fence you are now ready to

make

Plywood Handle

Finished Push

1-1/2"_._/___

1-1/2"

-_ 12"

Glue Onty_

Screw Head Must Be

Flush Or Recessed

, ,_,.

5"

3/8" Plywood Base

Auxiliary Fence

Making the base:

° Start with a piece of 3/8 inch plywood at least 5-1/2

inches wide or wider and 30 inches long or longer,

o Cut the piece to shape and size shown:

Making the side:

° Start with a piece of 3/4 inch plywood at least 2-3/8

inches wide or wider and 27 inches long or longer

• Cut the piece to shape and size shown:

Putting it together:

o Put the pieces together, as shown:

IMPORTANT: Make sure the screw heads do not stick

out from the bottom of the base, they must be flush or

recessed, The bottom must be flat and smooth enough to

rest on the saw table without rocking

Cutting Out the Base

30"

3E|-l!2r_L 3/8" Thick Plywood Base s /2

Cutting Out the Side

_'= Plywood27" _"_2_8

3/4" Thick Side "

Finished Auxiliary Fence

j_.1._.__._..___..." Plywood

L

This Face and

This Edge Must

Be Parallel

27

Loading ...

Loading ...

Loading ...