Loading ...

Loading ...

Loading ...

English 14

[ PRECAUTIONS ]

1. Do not ground the equipment on gas pipes, water pipes or

lightning rods, or crossground with telephones.

Improper grounding could result in electric shock.

2. The remote controller wiring (P

1 and P2) and transmission

wiring (F1 and F2) have no polarity.

10-3

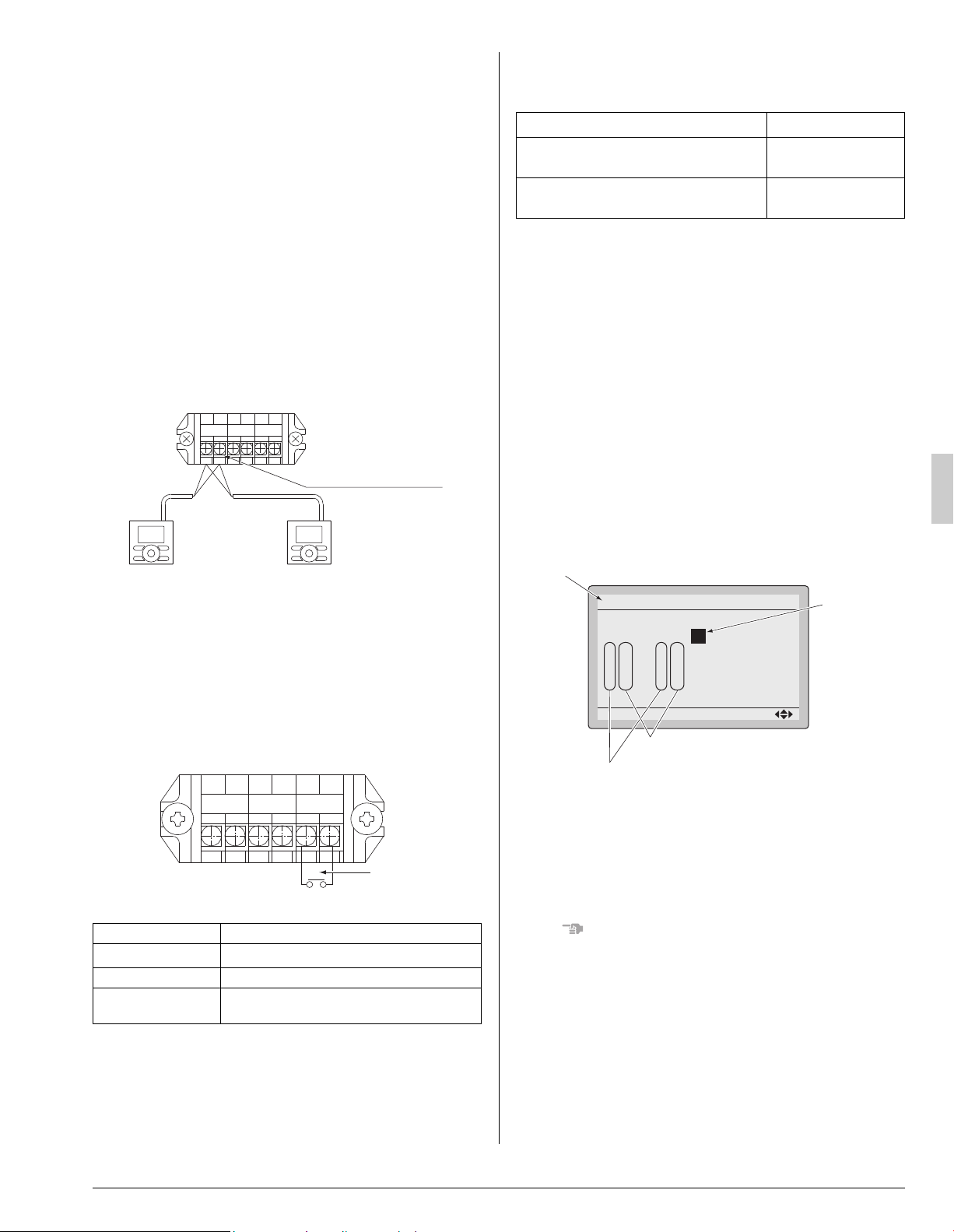

CONTROL BY 2 REMOTE CONTROLLERS (Con-

trolling 1 indoor unit by 2 remote controllers)

• When using 2 remote controllers, one must be set to “MAIN”

and the other to “SUB”.

Main/sub changeover

• Refer to the installation manual supplied with the remote con-

troller.

Wiring method

(1) Remove the control box cover.

(2) Add the remote controller 2 (SUB) to the terminal block for

remote controller (P

1, P2) in the control box. (There is no

polarity.)

10-4 REMOTE CONTROL (FORCED OFF AND ON/

OFF OPERATION)

(1) Wire specifications and how to perform wiring

• Connect input lines from the outside to the terminals T

1

and T2 on the terminal block (6P) for remote controller to

achieve remote control.

•See “11. FIELD SETTING” for details on operation.

(2) Actuation

• The following table explains FORCED OFF and ON/OFF

OPERATIONS in response to Input A.

(3) How to select FORCED OFF and ON/OFF OPERATION

• Turn the power on and then use the remote controller to

select operation.

10-5 CENTRALIZED CONTROL

• For centralized control, it is necessary to designate the group

No. For details, refer to the manual of each optional control-

lers for centralized control.

11. FIELD SETTING

Make sure the control box covers are closed on the indoor

and outdoor units.

Field setting must be made from the remote controller in

accordance with the installation conditions.

• Setting can be made by changing the “Mode No.”, “FIRST

CODE NO.”, and “SECOND CODE NO.”.

• For setting procedures and instructions, refer to the “Field

Settings” in the installation manual of the remote controller.

With wireless remote controller used

Set the wireless remote controller address before using the

wireless remote controller.

For the setting method of the address, refer to the operation

manual provided with the wireless remote controller.

NOTE

• Before the test operation as explained in 12. TEST OPERA-

TION, be sure to make the following field settings.

• A “Mode No.” is set on a group basis. To make a mode setting

on an individual unit basis or check the setting made, how-

ever, set the corresponding mode number in the parenthe-

ses.

Wire specification Sheathed vinyl cord or 2 core cable

Gauge

AWG18 – 16 (0.75-1.25 mm

2

)

Length Max. 328 ft. (100 m)

External terminal

Contact that can ensure the minimum appli-

cable load of 15 V DC, 1 mA.

1

P

2

P

1

F

2

F

1

T

2

T

FORCED

OFF

REMOTE

CONTRL

TRANSMISSION

WIRING

Remote controller wiring

terminal block

Remote

controller 2

(SUB)

Remote

controller 1

(MAIN)

Fig. 11

Input A

1

P

2

P

1

F

2

F

1

T

2

T

FORCED

OFF

REMOTE

CONTRL

TRANSMISSION

WIRING

Fig. 12

FORCED OFF ON/OFF OPERATION

Input “ON” stops operation (impossible by

remote controllers.)

Input OFF ON turns

ON unit.

Input OFF enables control by remote con-

troller.

Input ON OFF turns

OFF unit.

Unit No.

0

1

–

01

5

–––

9

–––

2

–

02

6

–––

a

–––

3

–

01

7

–––

b

–––

Field Settings

0

–

01

4

–––

8

–––

Setting

Mode

20

SECOND CODE NO.

FIRST CODE NO.

Mode No.

FIELD SET MODE

Fig. 13

01_EN_3P530815-1.fm Page 14 Tuesday, July 10, 2018 6:20 PM

Loading ...

Loading ...

Loading ...