Loading ...

Loading ...

Loading ...

7 English

CAUTION

• Use the level and check that the unit is installed horizontally.

(4-directions)

• In the case of using a vinyl tube (filled with water) in place of

the level, align the bottom of the unit to the water surface at

both edges of the vinyl tube to make levelness adjustment.

If the unit is installed at a slant with the drain pipe side set

high, in particular, the float switch will not operate normally

and water leakage may result.

6. REFRIGERANT PIPING WORK

As for the refrigerant piping of the outdoor unit, refer to the

installation manual provided to the outdoor unit.

Perform thermal insulation work on both gas piping and

liquid piping, or otherwise water leakage may result.

Use the insulation material that withstands a temperature

of 250°F (120°C).

Reinforce the insulation material for the refrigerant piping if

the ambient temperature is high, or otherwise dew conden-

sation may result on the surface of the insulation material.

Make sure that the refrigerant is R410A before refrigerant

piping work. If the refrigerant is different, the air condi-

tioner will not operate normally.

CAUTION

This product uses new refrigerant (R410A) only. Be sure to

keep the following items and conduct the installation work.

• Use a dedicated pipe cutter and a flaring tool for R410A.

• When connecting the flare, apply ether oil or ester oil

only to inner side of the flare.

• Be sure to use the flare nut provided with the unit. (Do

not use a different flare nut (such as a type-1 flare nut),

or otherwise refrigerant leakage may result.)

• To prevent contamination or moisture from getting into

the piping, take measures such as pinching or taping the

ends of the pipes.

• Be sure to use the specified type of refrigerant for the

refrigeration cycle and do not contaminate the refrigerant

with air.

• Ventilate the room in case of refrigerant leakage during

installation work.

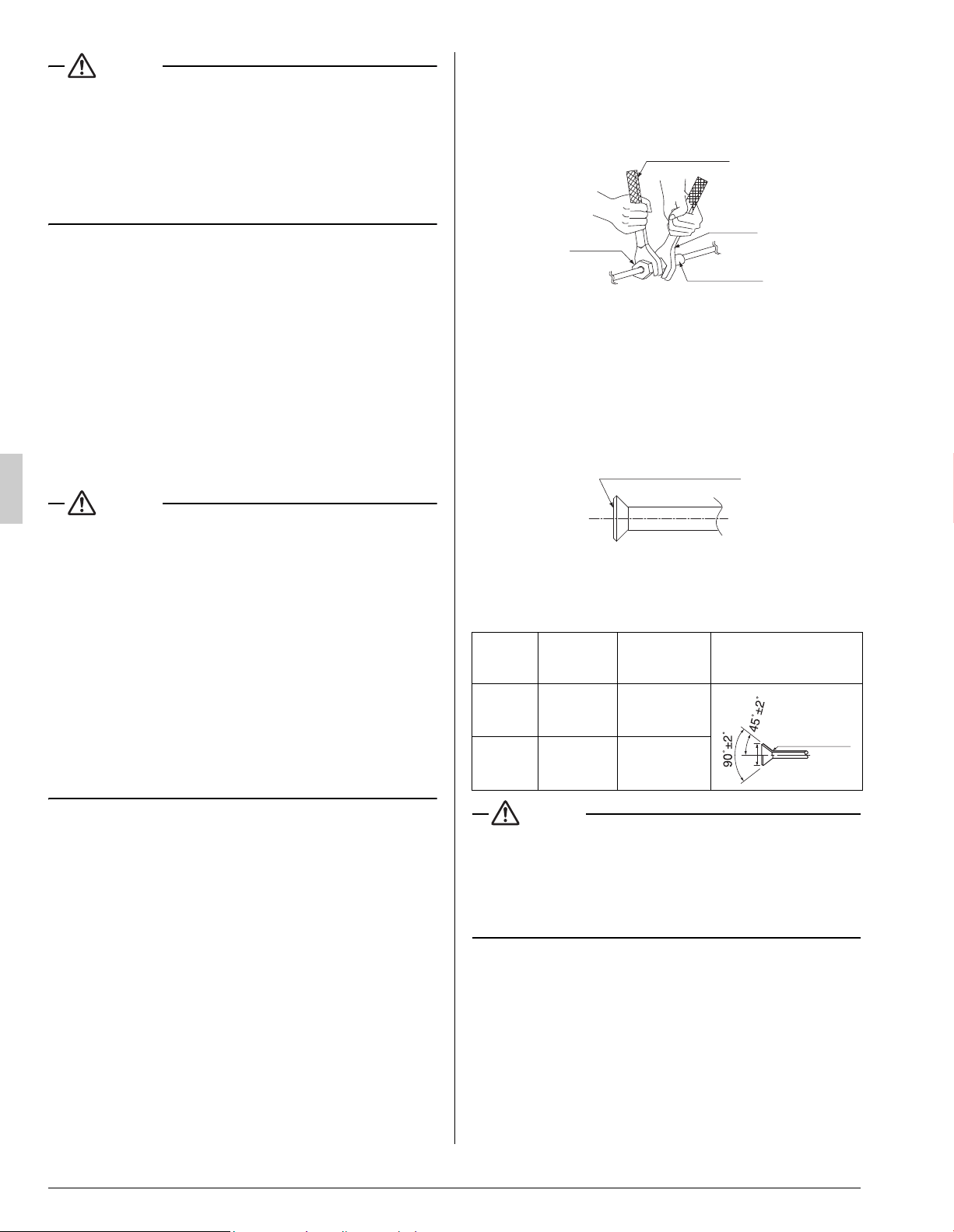

(1) Connect the piping.

• The refrigerant is pre-charged in the outdoor unit.

• When connecting or disconnecting piping to or from the

unit, be sure to use a spanner and a torque wrench.

(Refer to Fig. 4)

• Refer to Table 1 for the processing dimensions of the

flare.

• Use the flare nut provided with the unit.

• Apply ether oil or ester oil only to inner side of the

flare and screw in the flare nut three to four turns first by

hand at the time of connecting the flare nut.

(Refer to Fig. 5)

• Refer to Table 1 for the corresponding tightening torque.

Table 1

CAUTION

• Do not excessively tighten the flare nut.

Doing so will break the flare nut and refrigerant leakage may

occur.

• Make sure that all parts around the flare are free of oil.

The drain pan and the resin part may be deteriorated if oil is

attached.

Piping

size

[in. (mm)]

Tightening

torque

[lbf·ft. (N·m)]

Dimension for

processing flare

A [in. (mm)]

Flare shape

[in. (mm)]

3/8

(9.5)

24.1 – 29.4

(36.3±3.6)

0.504 – 0.520

(13.0±0.2)

5/8

(15.9)

45.6 – 55.6

(68.6±6.8)

0.760 – 0.776

(19.5±0.2)

Torque wrench

Spanner

Piping union

Flare nut

Fig. 4

Fig. 5

Apply ester oil or ether oil

only to inner side of flare.

R0.016-0.031

(0.4-0.8)

A

01_EN_3P530815-1.fm Page 7 Tuesday, July 10, 2018 6:20 PM

Loading ...

Loading ...

Loading ...