Loading ...

Loading ...

Loading ...

5 English

CAUTION

• Install the indoor and outdoor units, power supply wiring and

connecting wires at least 3.3 ft (1 m) away from televisions or

radios in order to prevent image interference or noise.

(Depending on the radio waves, a distance of 3.3 ft (1 m) may

not be sufficient enough to eliminate the noise.)

• In the case of the installation of the wireless remote controller,

the transmission distance of the wireless remote controller may

be shortened if the room has a fluorescent light of electronic

lighting type (i.e., an inverter or rapid-start fluorescent light).

Keep the distance between the receiver and the fluorescent

light as far as possible.

(2) Use suspension bolts to install the indoor unit. Check that

the place of installation withstands the weight of the indoor

unit. Secure the suspension bolts with proper beams if nec-

essary.

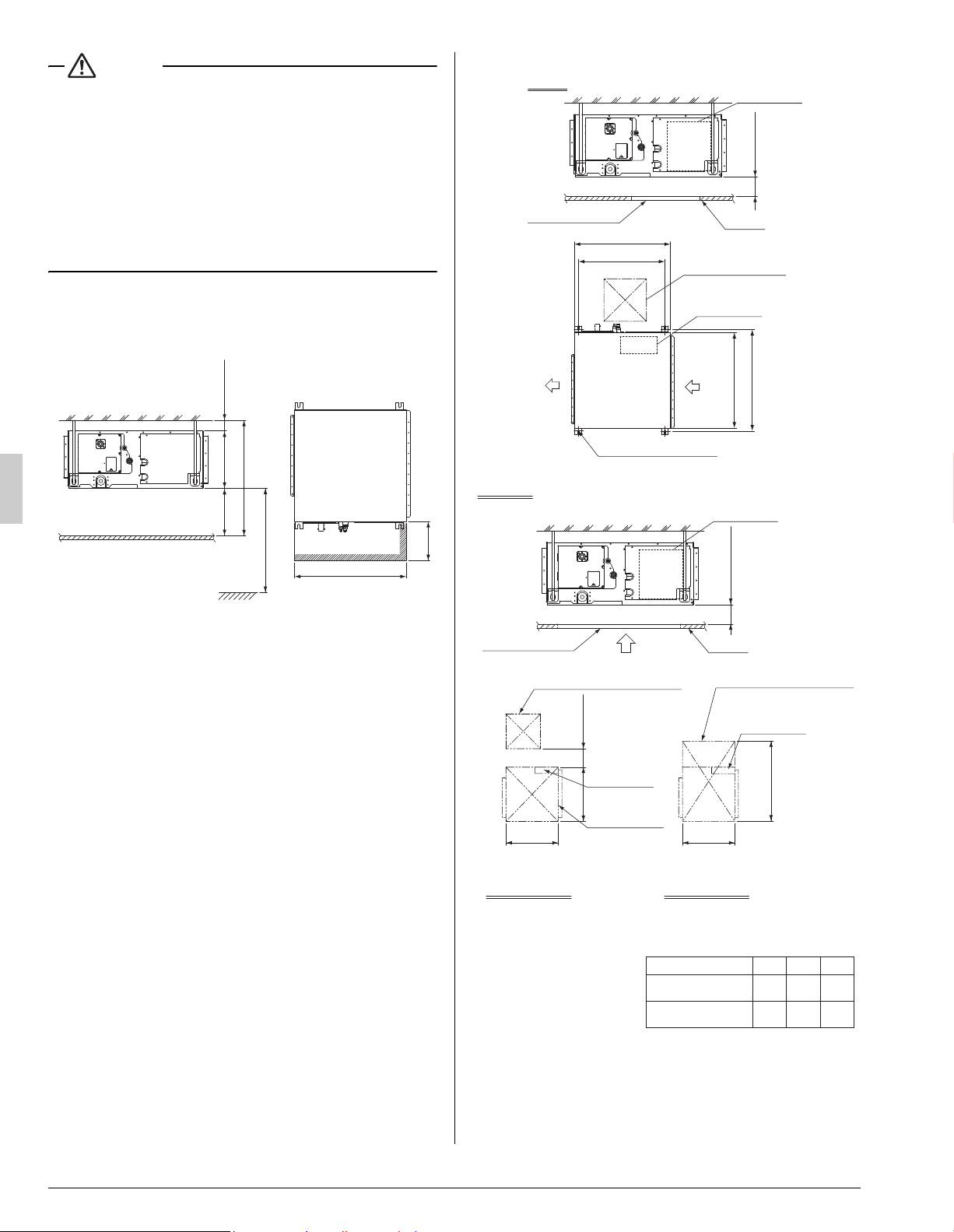

4. PREPARATIONS BEFORE INSTALLATION

(1) Check the positional relationship between the ceiling open-

ing hole and the suspension bolt of the unit. [unit: in. (mm)]

• For the maintenance, inspection, and other servicing

purposes of the control box and drain pump, prepare one

of the following service spaces.

1. Inspection hatch 1 (17-3/4 × 17-3/4 (450 × 450)) for

the control box and a minimum space of 12 in. (300)

for the lower part of the product. (Refer to Fig. 2-2)

2. Inspection hatch 1 (17-3/4 × 17-3/4 (450 × 450)) for

the control box and inspection hatch 2 for the lower

part of the product (see arrow view A-1). (Refer to

Fig. 2-3)

3. Inspection hatch 3 for the lower part of the product

and the lower part of the control box (see arrow view

A-2). (Refer to Fig. 2-3)

[unit: in. (mm)]

Ceiling

Floor surface

• The H1 dimension indicates the

height of the product.

• Determine the H2 dimension by

maintaining a downward slope of

at least 1/100 as specified in

“7. DRAIN PIPING WORK”.

Min. 1 (20)

Min. 12

(300)

Min. 18

(450)

Min. 99 (2500)

Min. 28 (700)

(service space)

(If no ceiling board is provided.)

*H1=12 (300)

*H2=Min. 25 (620)

[Required installation place]

The dimensions indicate the

minimum required space of

installation.

Fig. 2-1

28 (700)

24-13/16 (631)

(Suspension bolt pitch)

Inspection hatch 1

(17-3/4×17-3/4)

(450×450)

Inspection hatch

Control box

Control box

Ceiling

B

C

(Suspension bolt pitch)

Bottom of unit

Air inlet

Air outlet

Suspension bolt (× 4)

*H3=Min. 12

(300)

Fig. 2-2

Case 1

[unit: in. (mm)]

28 (700) 28 (700)

Inspection hatch

Inspection hatch 1

(17-3/4×17-3/4) (450×450)

Inspection

hatch 2

Inspection hatch 3

(Same as the indoor

unit size +12 (300) or more)

Control box

Control box

Control box

Inspection hatch

(Ceiling opening)

Ceiling

Arrow view A-1 Arrow view A-2

Min. D=B+12

(300)

Min. 8 (200)

B

*H3=Min. 3/4 (20)

Model B C D

40

(1000)

40-7/8

(1038)

52

(1300)

56

(1400)

56-5/8

(1438)

68

(1700)

18 • 24 • 30 type

36 • 42 • 48 type

[unit: in. (mm)]

A

Fig. 2-3

Case 2, 3

(Same as the

indoor unit

size or more)

• Determine the H3

dimension by maintaining a

downward slope of at least

1/100 as specified in

“7. DRAIN PIPING WORK”.

01_EN_3P530815-1.fm Page 5 Tuesday, July 10, 2018 6:20 PM

Loading ...

Loading ...

Loading ...