Loading ...

Loading ...

Loading ...

English 10

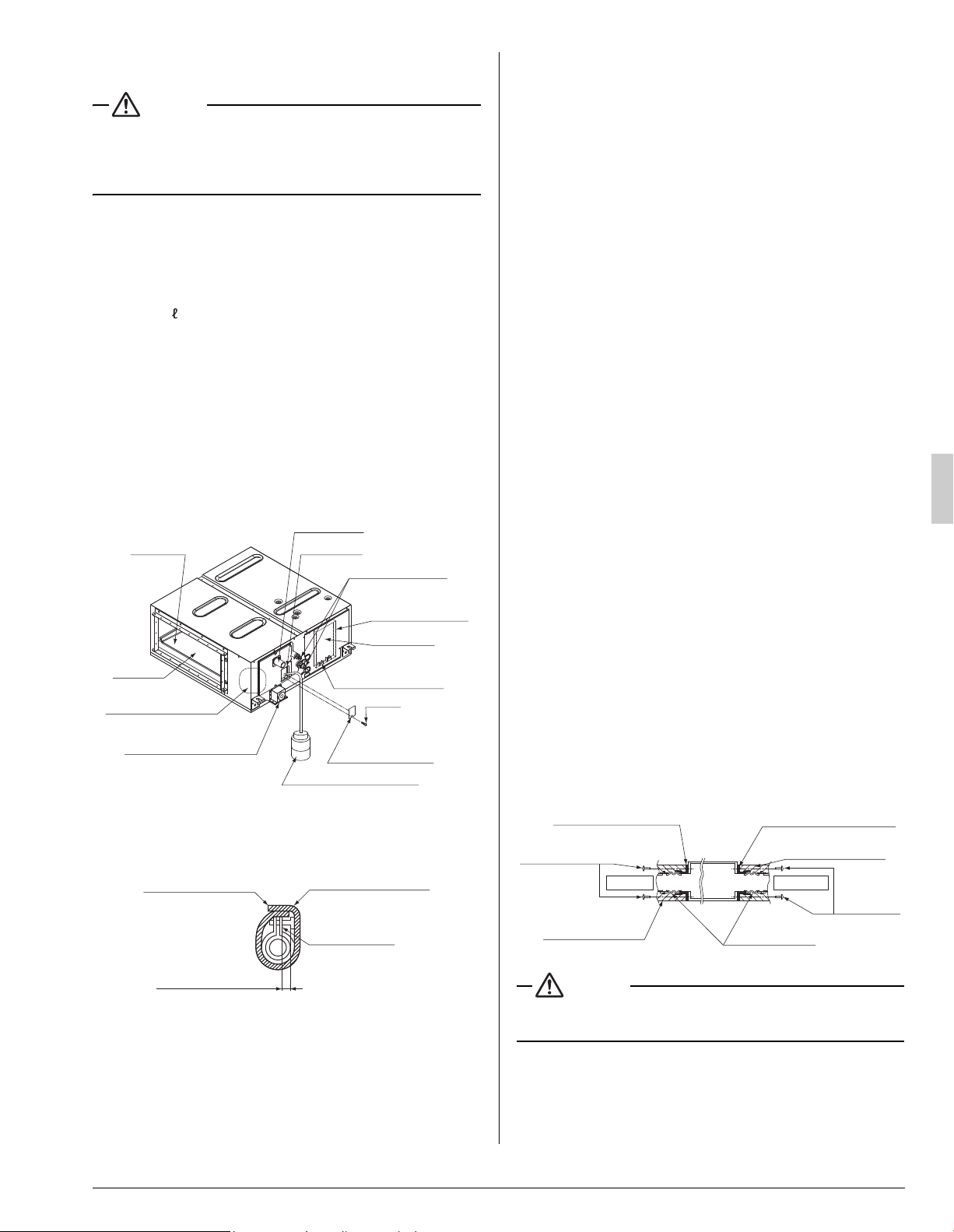

The drainage can be checked with the water level change

in the drain pan through the water inlet.

CAUTION

• Do not touch the drain pump.

Otherwise, an electric shock may be received.

• Do not impose external force on the float switch.

Otherwise, a failure may result.

5. On completion of the drainage check, shut off the power

supply and disconnect the power supply wiring.

6. Put the control box cover to the original position.

[After electrical work]

• After completion of 8. DUCT WORK provide approximately

1/4 gal (1 ) of water gradually into the drain pan through the

water inlet on the bottom of the drain socket, and check that

the water is drained while the air conditioner is in cooling

operation according to 11. FIELD SETTING and 12. TEST

OPERATION. Make sure that the water is not spilled onto the

electric parts of the drain pump and others.

(3) Be sure to conduct thermal insulation work on the fol-

lowing portions, or otherwise water leakage may occur

as a result of dew condensation.

• Drain piping indoors

• Drain socket

• On completion of the drainage check, refer to the follow-

ing illustration, and use the provided large sealing pad

(6) and insulate the metal clamp (1) and drain hose (2).

8. DUCT WORK

Pay utmost attention to the following items and conduct

ductwork.

• Check that the duct will not be in excess of the setting range

of external static pressure for the unit. (Refer to Engineering

Data for the setting range. Each model has each setting

range of external static pressure.)

• Attach a canvas duct each to the air outlet and air inlet so that

the vibration of the equipment will not be transmitted to the

duct or ceiling.

Use a sound-absorbing material (insulation material) for the

lining of the duct and apply vibration insulation rubber to the

suspension bolts.

• At the time of duct welding, protect the opening of the duct so

that the sputter will not come in contact with the drain pan or

the filter.

• If the metal duct pass through a metal lath, wire lath, or metal

plate of a wooden structure, separate the duct and wall elec-

trically.

• Be sure to insulate the duct for the prevention of dew conden-

sation. (Material: Glass wool or styrene foam; Thickness:

1 in. (25 mm))

• Be sure to attach a field supplied air filter to the air inlet of the

unit or field supplied inlet in the air passage on the air suction

side. (Be sure to select an air filter with a duct collection effi-

ciency of 50 weight percent.)

• Explain the operation and cleaning method of the field sup-

plied components (i.e., the air filter, air inlet grille, and air out-

let grille) to the customer.

• Locate the air outlet grille on the indoor side for the preven-

tion of drafts in a position where indirect contact with people.

• The air conditioner incorporates a function to adjust the fan to

rated speed automatically. (11. FIELD SETTING)

Therefore, do not use booster fans midway in the duct.

Connection method of ducts on air inlet and outlet sides.

• Connect the field supplied duct in alignment with the inner

side of the flange.

• Connect the flange and unit with the flange connection screw

(3).

• Wrap aluminum tape around the flange and duct joint in order

to prevent air leakage.

CAUTION

Connect the flange to the unit with the flange connection screw

(3) even in case of no duct connection.

Water inlet

Drain socket

Drain pan

Control box cover

Terminal block for

power supply

Screw

Water inlet cover

Control box

Refrigerant piping

Air outlet

Socket for maintenance

(with rubber cap)

Drain pump position

Plastic water container

Make sure that the

seam faces upward.

Metal clamp (1)

(accessory)

Large sealing pad (6)

(accessory)

3/16 in. (4 mm) max.

Unit

Flange on air outlet side

(provided with the unit)

Insulation material

(field supply)

Canvas duct

(field supply)

Flange on air inlet side

(provided with the unit)

Insulation material

(field supply)

Air inlet

Air outlet

Screws for duct

flanges (3)

(accessory)

Screws

for duct

flanges (3)

(accessory)

01_EN_3P530815-1.fm Page 10 Tuesday, July 10, 2018 6:20 PM

Loading ...

Loading ...

Loading ...