Loading ...

Loading ...

Loading ...

SERVICE AND ADJUSTMENTS

TO REPLACE AUGER SHEAR BOLT

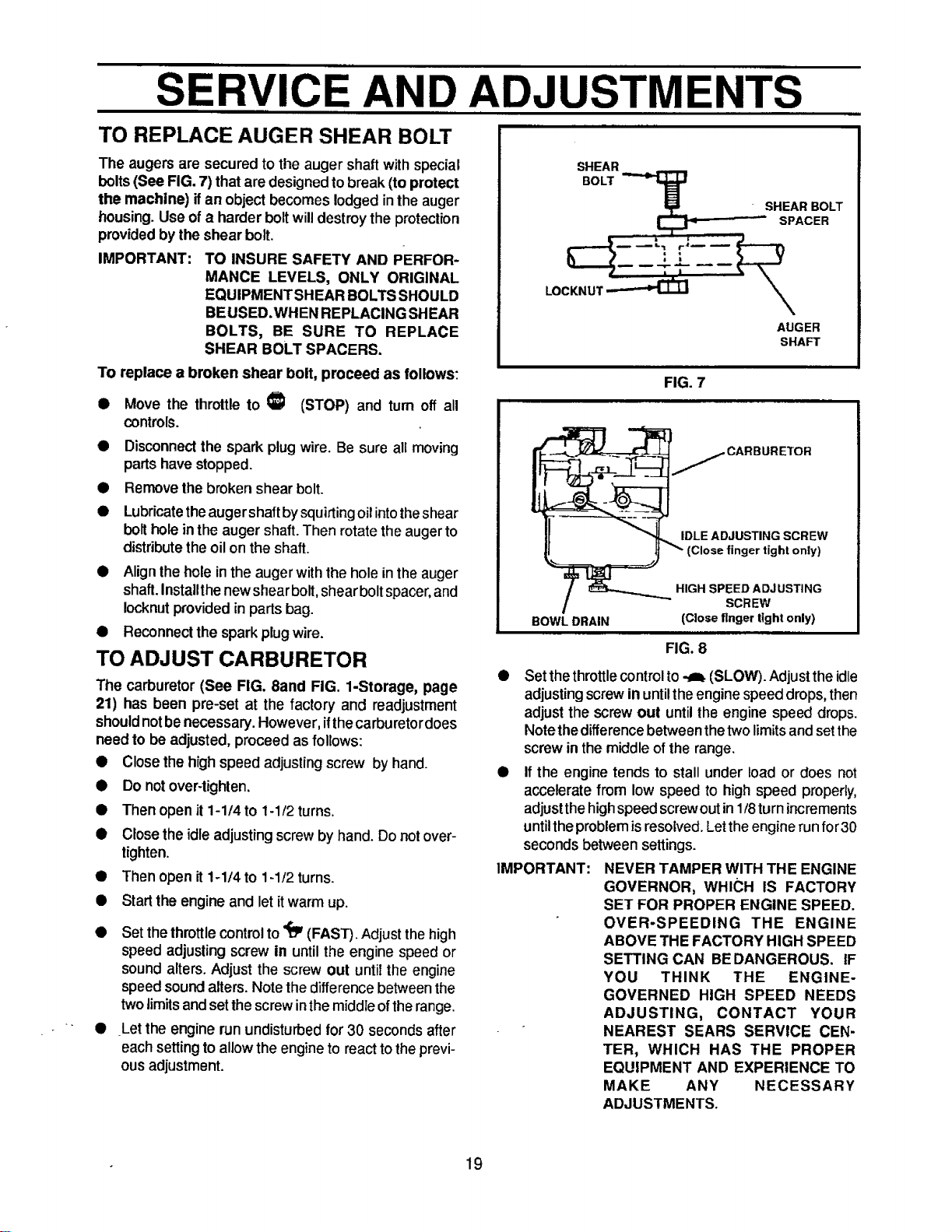

The augers are secured to the auger shaft with special

bolts (See FIG. 7) that are designed to break (to protect

the machine) if an object becomes lodged inthe auger

housing. Use of a harder bolt will destroy the protection

provided by the shear bolt.

IMPORTANT:

TO INSURE SAFETY AND PERFOR-

MANCE LEVELS, ONLY ORIGINAL

EQUIPMENTSHEAR BOLTS SHOULD

BEUSED.WHEN REPLACING SHEAR

BOLTS, BE SURE TO REPLACE

SHEAR BOLT SPACERS.

TO replace a broken shear bolt, proceed as follows:

• Move the throttle to €I (STOP) and turn off all

controls.

• Disconnect the spark plug wire. Be sure all moving

parts have stopped.

• Remove the broken shear bolt.

• Lubricate theaugershaft bysquirting oil intothe shear

bolt hole in the auger shaft. Then rotate the auger to

distribute the oil on the shaft.

• Align the hole in the auger with the hole in the auger

shaft. Insta]lthe new shear bolt, shear boltspacer,and

Iocknut provided in parts bag.

• Reconnect the spark plugwire.

TO ADJUST CARBURETOR

The carburetor (See FIG. 8and FIG. 1-Storage, page

21) has been pre-set at the factory and readjustment

shouldnotbe necessary.However,ifthecarburetordoes

need to be adjusted,proceed as follows:

• Close the high speed adjusting screw by hand.

Do not over-tighten.

Then open it 1-1/4 to 1-1/2 turns.

Close the idleadjusting screw by hand. Do notover-

tighten.

Then open it1-1/4 to 1-1/2 turns.

Start the engine and let itwarm up.

• Set thethrottlecontrol to_ (FAST). Adjust thehigh

speed adjusting screw in until the engine speed or

sound alters. Adjust the screw out until the engine

speed sound alters. Note the difference between the

two limits and set the screw inthemiddle of therange.

• Let the engine run undisturbed for 30 seconds after

each setting to allow the engine to react tothe previ-

ous adjustment.

SHEAR

BOLT

I_ SHEAR BOLT

LI _ -:" SPACER

AUGER

SHAFT

FIG. 7

'_E ADCARBURET°R

JUSTING SCREW

(Close finger tight only)

IGH SPEED ADJUSTING

SCREW

BOWL DRAIN (Close finger tight only)

FIG. 8

IMPORTANT:

Set thethrottlecontrol to._ (SLOW). Adjustthe idle

adjusting screw in untilthe engine speed drops, then

adjust the screwout untilthe engine speed drops.

Note thedifferencebetween thetwo limitsand setthe

screw inthe middleofthe range.

If the engine tends to stall under load or does not

accelerate from low speed to high speed properly,

adjustthehighspeed screwoutin1/8turnincrements

untiltheproblemis resolved.Lettheenginerun for30

secondsbetween settings.

NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY

SET FOR PROPER ENGINE SPEED.

OVER-SPEEDING THE ENGINE

ABOVE THE FACTORY HIGH SPEED

SETTING CAN BEDANGEROUS. IF

YOU THINK THE ENGINE-

GOVERNED HIGH SPEED NEEDS

ADJUSTING, CONTACT YOUR

NEAREST SEARS SERVICE CEN-

TER, WHICH HAS THE PROPER

EQUIPMENT AND EXPERIENCE TO

MAKE ANY NECESSARY

ADJUSTMENTS.

19

Loading ...

Loading ...

Loading ...