Loading ...

Loading ...

Loading ...

24 25

INSTALLATIONINSTALLATION

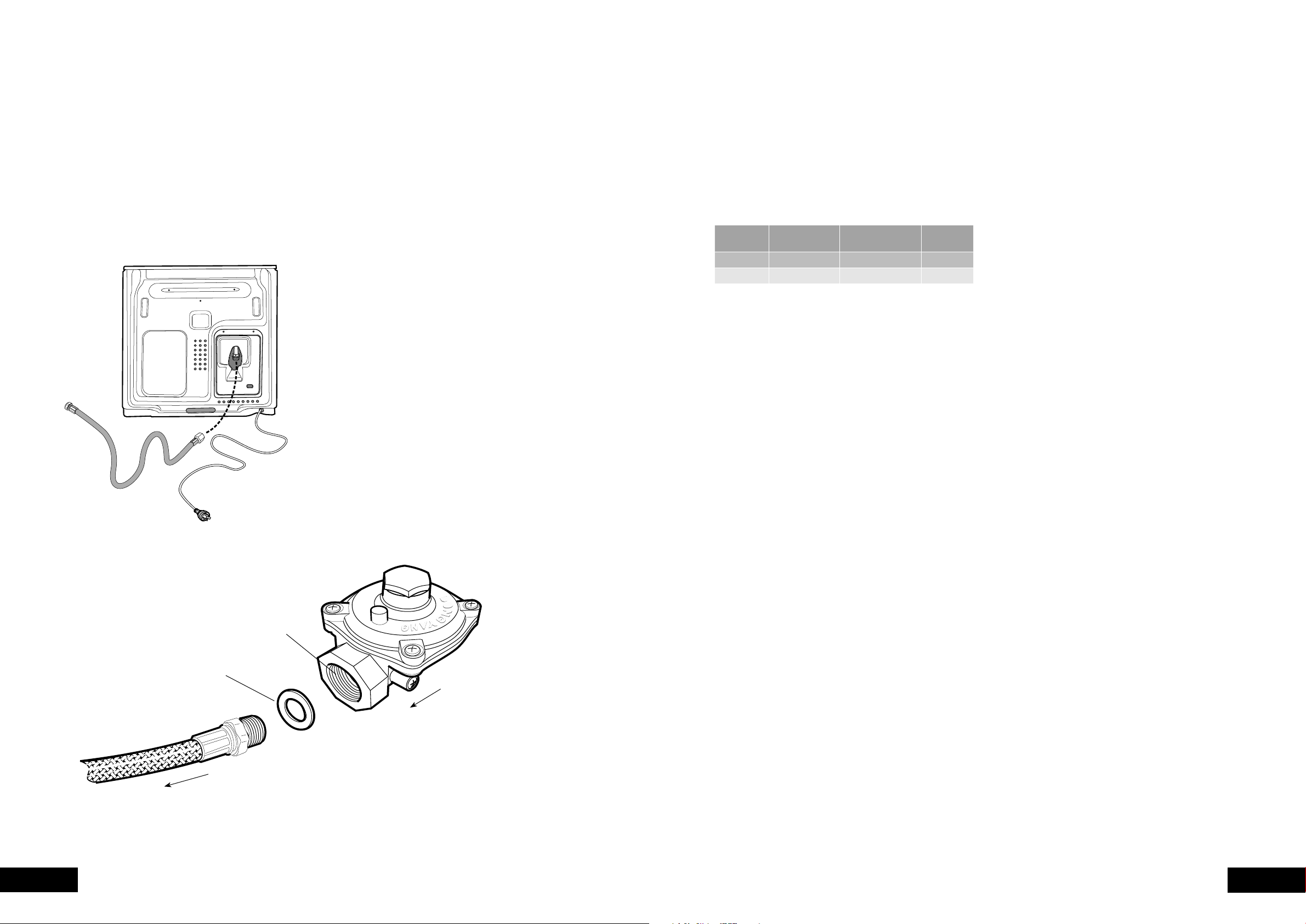

Gas Connection

of gas to which the appliance is intended to be connected

matches the gas type given on the appliance data plate.

determine gas type. A gas type label is located on the

back panel near the gas inlet.

A 1700mm long flexible hose is supplied in the pack for

installation purposes.

Connecting flexible hose

Place a spanner on the flats provided on the gas inlet

to brace the inlet against the action of wrenching when

connecting the hose to the appliance gas inlet. Failure to

do so may damage the appliance.

An approved thread sealing tape or compound is

appliance gas inlet.

Appliances for operation on N.G. & S.N.G.

For N.G. and S.N.G appliances the supplied N.G. regulator

must be fitted. For L.P.G appliances (Propane or

Universal LP) the test point fitting supplied must be fitted.

NOTE: The inlet of the regulator or test point fitting should

be fitted to the consumer piping first. The arrow on the

regulator or test point fitting indicates the direction of gas

flow. Then connect the hose to the outlet of the regulator

or test point fitting using the swivel connection on the hose

and fibre washer supplied.

Ensure the regulator or test point fitting is in

a position that is accessible with the appliance

installed and which will allow the appliance to

be withdrawn without disconnecting the hose.

GAS INSTALLATION INFORMATION

Operating Pressures

GAS TYPE

SUPPLY PRESSURE

(KPA)

NOMINAL TEST POINT

PRESSURE (KPA)

OVEN

INJECTOR

1.13 - 5.00 1.00 1.50

2.75 2.75 0.82

Testing the Operation of the Appliance

safeguard system, which includes a safety shutdown

function that operates when the presence of a flame is not

detected within a prescribed period.

system in order to facilitate purging of air from the appliance.

monitored to ensure that the ignition spark can be observed

through the round hole in the left hand side of the cover on

the bottom of the oven, and that the solenoid valve can be

heard to open and close.

1. After connecting the gas and leak testing the gas connection,

plug in the service cord and turn on the power.

3. Purging procedure:

a. Turn on the oven

b. The unit will commence sparking and the solenoid

established, the controller will shut the solenoid valve

and stop sparking, then pause for a moment before

repeating this cycle. At this point if there is still no

flame, the control system will go into safety shutdown.

c.

turn off all the controls and switch off the power

supply for a few seconds.

d. Then turn the power back on and repeat steps 2.

through to 3.d. until the gas ignites.

NOTE:

shutdown before a new ignition cycle can be attempted.

5.

6.

(this may be remote from the cooker).

the nominal outlet pressure of 1.00kPa by more than ±0.20kPa.

then check the following points.

a.

inlet pressure may be too low and adjustment of an

upstream regulator may be needed, or an upstream

regulator or valve with insufficient flow capacity may

then it may be necessary to repeat the checks whilst

measuring both the inlet and outlet pressure to determine

b.

supply line in the correct orientation, the arrow on the

base of the body indicates the direction of gas flow.

still fails to perform in a satisfactory manner it should be

replaced.

7.

is much larger or much smaller than expected, the

is unsatisfactory refer to the servicing instructions and

correct the fault if possible.

inform the customer of the problem and affix an appropriate

be dangerous, the appliance should be disconnected.

However, if only a minor fault exists, the customer may

wish to use the appliance while awaiting service.

The customer should be advised that, in the event of a fault,

or the retailer from whom the appliance was purchased.

GAS INSTALLATION INFORMATION

Gas flow

to appliance

N.G. Regulator

must be installed

Loading ...

Loading ...

Loading ...