Loading ...

Loading ...

Loading ...

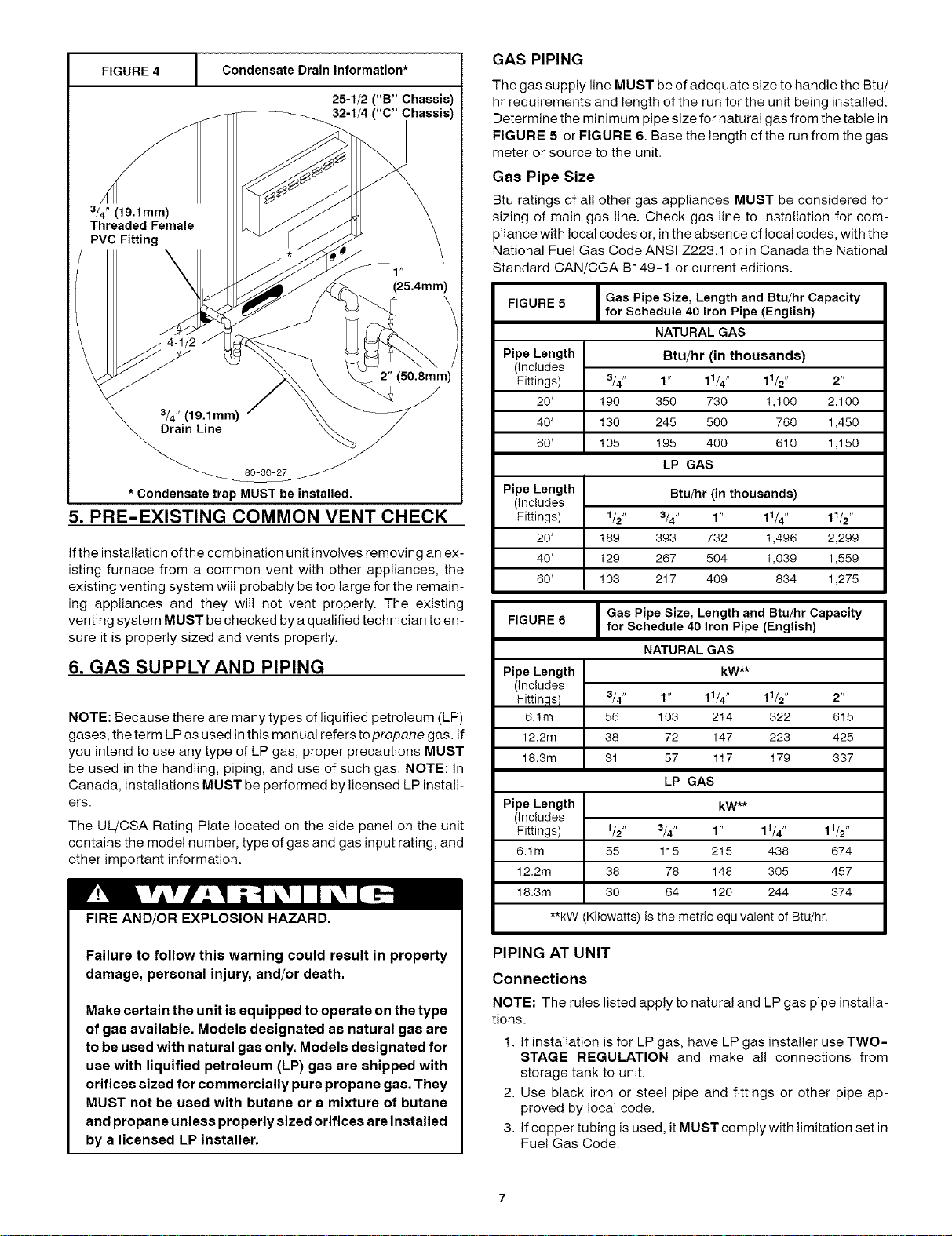

FIGURE 4 [ GAS PIPING

Condensate Drain Information*

25-1/2 ("B" Chassis)

32-1/4 ("C" Chassis)

3/4" (19.1mm)

Threaded Female

(25.4mm)

2" (50.8mm)

* Condensate trap MUST be installed,

5. PRE-EXISTING COMMON VENT CHECK

If the installation of the combination unit involves removing an ex-

isting furnace from a common vent with other appliances, the

existing venting system wil! probably be too large for the remain-

ing appliances and they will not vent properly. The existing

venting system MUST be checked by a qualified technician to en-

sure it is properly sized and vents properly.

6. GAS SUPPLY AND PIPING

NOTE: Because there are many types of liquified petroleum (LP)

gases, the term LP as used in this manual refers topropane gas. If

you intend to use any type of LP gas, proper precautions MUST

be used in the handling, piping, and use of such gas. NOTE: In

Canada, installations MUST be performed by licensed LP install-

ers.

The UL/CSA Rating Plate located on the side panel on the unit

contains the model number, type of gas and gas input rating, and

other important information.

FIRE AND/OR EXPLOSION HAZARD.

Failure to follow this warning could result in property

damage, personal injury, and/or death.

Make certain the unit is equipped to operate on the type

of gas available. Models designated as natural gas are

to be used with natural gas only. Models designated for

use with liquified petroleum (LP) gas are shipped with

orifices sized for commercially pure propane gas. They

MUST not be used with butane or a mixture of butane

and propane unless properly sized orifices are installed

by a licensed LP installer.

The gas supply line MUST be of adequate size to handle the Btu/

hr requirements and length of the run for the unit being installed.

Determine the minimum pipe size for natural gas from the table in

FIGURE 5 or FIGURE 6. Base the length of the run from the gas

meter or source to the unit.

Gas Pipe Size

Btu ratings of all other gas appliances MUST be considered for

sizing of main gas line. Check gas line to installation for com-

pliance with local codes or, in the absence of local codes, with the

National Fuel Gas Code ANSI Z223.1 or in Canada the National

Standard CAN/CGA B149-1 or current editions.

FIGURE 5 Gas Pipe Size, Length and Btu/hr Capacity

for Schedule 40 Iron Pipe (English)

NATURAL GAS

Pipe Length

(Includes

Fittings)

20'

Btu/hr (in thousands)

3/4" 1" 11/4" 11/2" 2"

190 350 730 1,100 2,100

40' 130 245 500 760 1,450

60' 105 195 400 610 1,150

LP GAS

Pipe Length Btu/hr (in thousands)

(Includes

Fittings) 1/2" 3/4" 1" 11/4" 11/2"

20' 189 393 732 1,496 2,299

40' 129 267 504 1,039 1,559

60' 103 217 409 834 1,275

Gas Pipe Size, Length and Btu/hr Capacity

FIGURE 6 for Schedule 40 Iron Pipe (English)

NATURAL GAS

Pipe Length kW**

(includes

Fittin,qs) 3/4" 1" 11/4" 11/2" 2"

6.1m 56 103 214 322 615

12.2m 38 72 147 223 425

18.3m 31 57 117 179 337

LP GAS

Pipe Length kW**

(includes

Fittings) 1/2" 3/4" 1" 11/4" 11/2"

6.1m 55 115 215 438 674

12.2m 38 78 148 305 457

18.3m 30 64 120 244 374

**kW (Kilowatts) is the metric equivalent of Btu/hr.

PIPING AT UNIT

Connections

NOTE: The rules listed apply to natural and LP gas pipe installa-

tions.

1. Ifinstallation is for LP gas, have LP gas installer use TWO-

STAGE REGULATION and make all connections from

storage tank to unit.

2. Use black iron or steel pipe and fittings or other pipe ap-

proved by local code.

3. Ifcopper tubing is used, it MUST comply with limitation set in

Fue! Gas Code.

Loading ...

Loading ...

Loading ...