Loading ...

Loading ...

Loading ...

3. SAFE INSTALLATION REQUIREMENTS

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the ANSI Z223.1 and the National Elec-

trical Code NFPA70-current edition or in Canada the

National Standard CAN/CGA B149-1 and CSA C.22.1 -

Canadian Electrical Code Part 1.

Failure to carefully read and follow all instructions in

this manual could result in furnace malfunction, prop-

erty damage, personal injury and/or death.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools

and test instruments.

• Do NOT use this furnace as a construction heater.

• Use only the Type of gas approved for this furnace (See Rating

Plate),

• Do NOT use open flame to test for gas leak.

• Seal supply and return air ducts.

• Check to see that filters are installed correctly and are the proper

type and size.

NOTE: It is the personal responsibility and obligation of the cus-

tomer to contact aqualified installer to ensure that the installation

is adequate and conforms to governing codes and ordinances.

FIRE, EXPLOSION, OR CARBON MONOXIDE POISONING

HAZARDS

Failure to have the furnace inspected and maintained

could result in death, bodily injury, and/or property

damage.

It is recommended that a qualified service technician

check the heat exchanger integrity every two (2) years,

after the first four (4) years of operation.

4. LOCATING THE UNIT

ACCESS PANELS

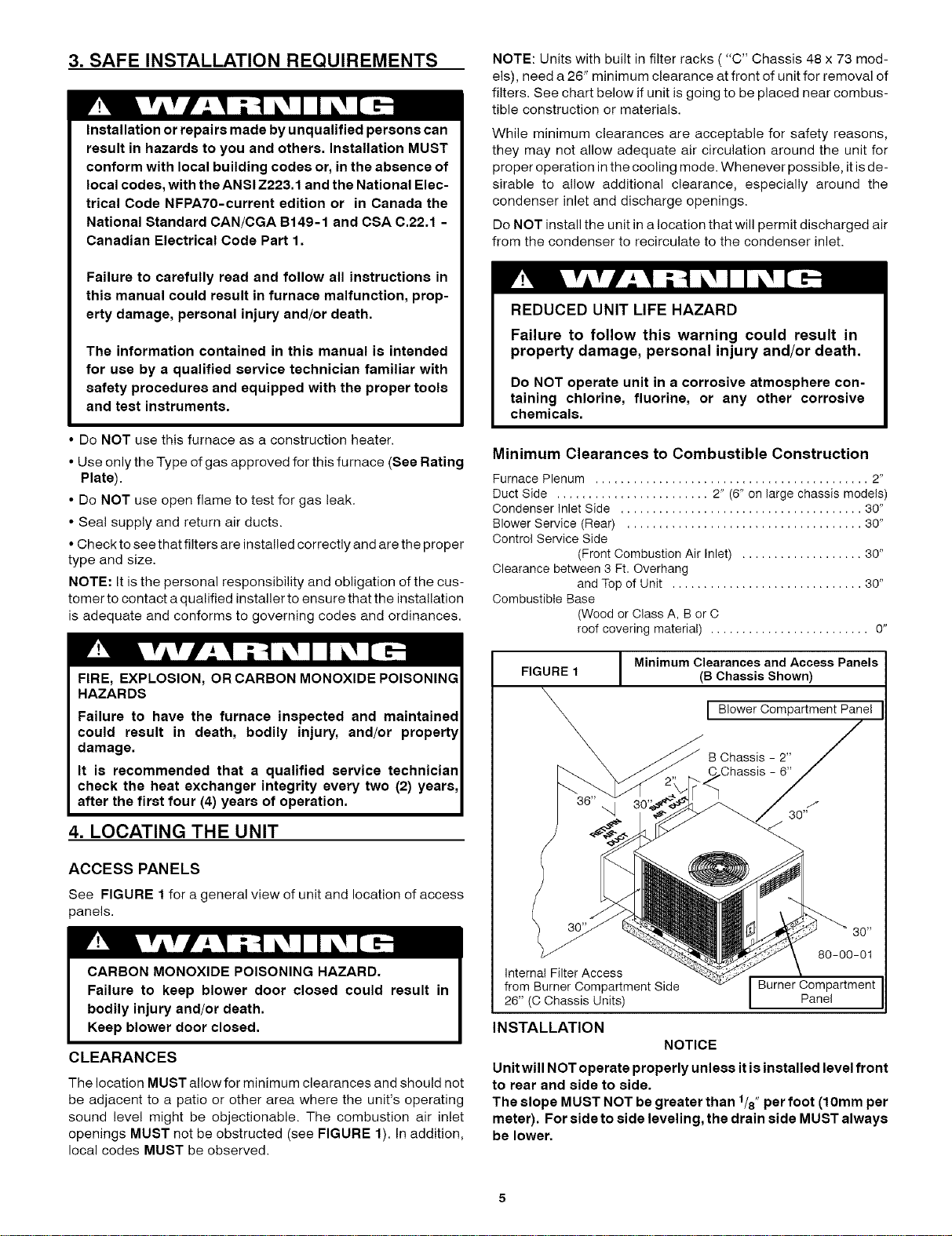

See FIGURE 1 for a general view of unit and location of access

panels.

CARBON MONOXIDE POISONING HAZARD.

Failure to keep blower door closed could result in

bodily injury and/or death.

Keep blower door closed.

CLEARANCES

The location MUST allow for minimum clearances and should not

be adjacent to a patio or other area where the unit's operating

sound level might be objectionable. The combustion air inlet

openings MUST not be obstructed (see FIGURE 1). In addition,

local codes MUST be observed.

NOTE: Units with built in filter racks ( "C" Chassis 48 x 73 mod-

els), need a 26" minimum clearance at front of unit for removal of

filters. See chart below if unit is going to be placed near combus-

tible construction or materials.

While minimum clearances are acceptable for safety reasons,

they may not allow adequate air circulation around the unit for

proper operation in the cooling mode. Whenever possible, it is de-

sirable to allow additional clearance, especially around the

condenser inlet and discharge openings.

Do NOT install the unit in a location that will permit discharged air

from the condenser to recirculate to the condenser inlet.

REDUCED UNIT LIFE HAZARD

Failure to follow this warning could result in

property damage, personal injury and/or death.

Do NOT operate unit in a corrosive atmosphere con-

taining chlorine, fluorine, or any other corrosive

chemicals.

Minimum Clearances to Combustible Construction

Furnace Plenum ........................................... 2"

Duct Side ........................ 2" (6" on large chassis models)

Condenser Inlet Side ...................................... 30"

Blower Service (Rear) ..................................... 30"

Control Service Side

(Front Combustion Air Inlet) ................... 30"

Clearance between 3 Ft. Overhang

and Top of Unit .............................. 30"

Combustible Base

(Wood or Class A, B or C

roof covering material) ......................... 0"

FIGURE 1

\

I Minimum Clearances and Access Panels

(B Chassis Shown)

I Blower Compartment Panel

Internal Filter Access

from Burner Compartment Side

26" (C Chassis Units)

INSTALLATION

NOTICE

80-00-01

Burner Compartment

Panel

Unit will NOT operate properly unless it is installed level front

to rear and side to side.

The slope MUST NOT be greater than 1/8" per foot (10mm per

meter). For side to side leveling, the drain side MUST always

be lower.

Loading ...

Loading ...

Loading ...