Loading ...

Loading ...

Loading ...

Ground Level Installation

Ground level platform requirements:

- The unit MUST be situated to provide safe access for servic-

ing.

Platform may be made of either concrete or pressure treated

wood and MUST be level and strong enough to support unit

weight.

Position platform separate from building foundation.

Install in well-drained area, with top surface of platform

above grade level.

Platform must be high enough to allow for proper condensate

trap installation and drainage. See FIGURE 4 and

associated text for more information about condensate

drainage.

Rooftop Installation

Rooftop platform requirements:

- The unit MUST be situated to provide safe access for servic-

ing.

- The existing roof structure MUST be adequate to support the

weight of the unit or the roof MUST be reinforced.

Check the weight of the unit in relation to the roof structure

and local building codes or ordinances and reinforce roof

structure if necessary. See FIGURE 21 in the back cover of

this manual for unit weights.

- Support for the unit MUST be level and strong enough to

carry unit weight. The support may consist of a platform or a

combination of platform and roof beams or curb.

- See Hoisting section below for hoisting instructions.

HOISTING

NOTE: All access panels MUST be secured in place before hoist-

ing.

The unit should be hoisted with two lifting slings. Attach the slings

to rigging shackles that have been hooked through holes in the

base rail.

Two spreader bars MUST be placed on top of the unit to protect

the unit from damage from the pressure exerted by the slings.

Make sure that all equipment is adequate to handle the weight of

the unit and that the slings will not allow the unit to shift.

Refer to FIGURE 21 on the back cover of this manual for illus-

trated rigging instructions and weight chart.

DOWNFLOW CONVERSION

These units are adaptable to downflow use. To convert to down-

flow use, follow these steps:

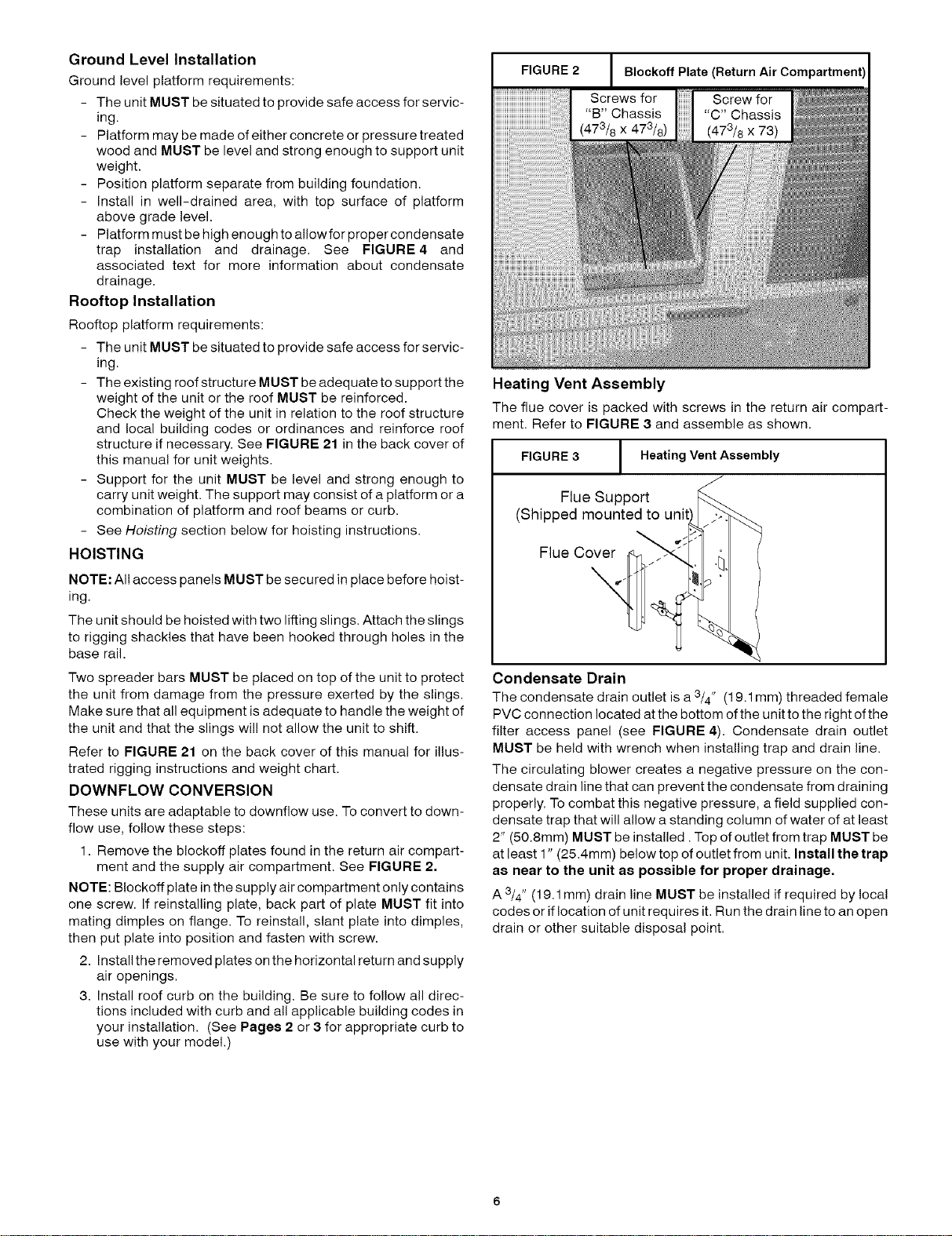

1. Remove the blockoff plates found in the return air compart-

ment and the supply air compartment. See FIGURE 2.

NOTE: Blockoff plate in the supply air compartment only contains

one screw. If reinstalling plate, back part of plate MUST fit into

mating dimples on flange. To reinstall, slant plate into dimples,

then put plate into position and fasten with screw.

2. Install the removed plates on the horizontal return and supply

air openings.

3. Install roof curb on the building. Be sure to follow all direc-

tions included with curb and all applicable building codes in

your installation. (See Pages 2 or 3 for appropriate curb to

use with your model.)

FIGURE 2 Blockoff Plate (Return Air Compartment)

Heating Vent Assembly

The flue cover is packed with screws in the return air compart-

ment, Refer to FIGURE 3 and assemble as shown.

FIGURE 3 _ Heating Vent Assembly

1

Flue Support

(Shipped mounted to unil

Flue Cover

\

Condensate Drain

The condensate drain outlet is a 3/4" (19.1 mm) threaded female

PVC connection located atthe bottom of the unit to the right ofthe

filter access panel (see FIGURE 4). Condensate drain outlet

MUST be held with wrench when installing trap and drain line.

The circulating blower creates a negative pressure on the con-

densate drain line that can prevent the condensate from draining

properly. To combat this negative pressure, a field supplied con-

densate trap that will allow a standing column of water of at least

2" (50.8mm) MUST be installed. Top of outlet from trap MUST be

at least 1" (25.4mm) below top of outlet from unit. Install the trap

as near to the unit as possible for proper drainage.

A 3/4" (19.1 mm) drain line MUST be installed if required by local

codes or if location of unit requires it. Run the drain line to an open

drain or other suitable disposal point.

Loading ...

Loading ...

Loading ...