Loading ...

Loading ...

Loading ...

onds.Oncethethermostatissatisfied,thefancontrolwil!operate

theblowerfor30additionalseconds.

SCROLL ANTI-CYCLE TIMER

Single phase scroll compressor equipped units are equipped with

an anti-cycle device which delays start of the compressor in the

event of a power interruption. This feature is to allow pressure

equalization throughout the system and to prevent possible re-

verse rotation of the scroll compressor.

11. MAINTENANCE

MONTHLY MAINTENANCE AND INSPECTION

CHECKS

Air Filters

inspect filters at least monthly and replace or clean as required.

Washable filters may be cleaned bysoaking in mild detergent and

rinsing with cold water. Replace filters with the arrows on the side

pointing in the direction of air flow. Dirty filters are the most com-

mon cause of inadequate heating or cooling performance, and of

compressor failures.

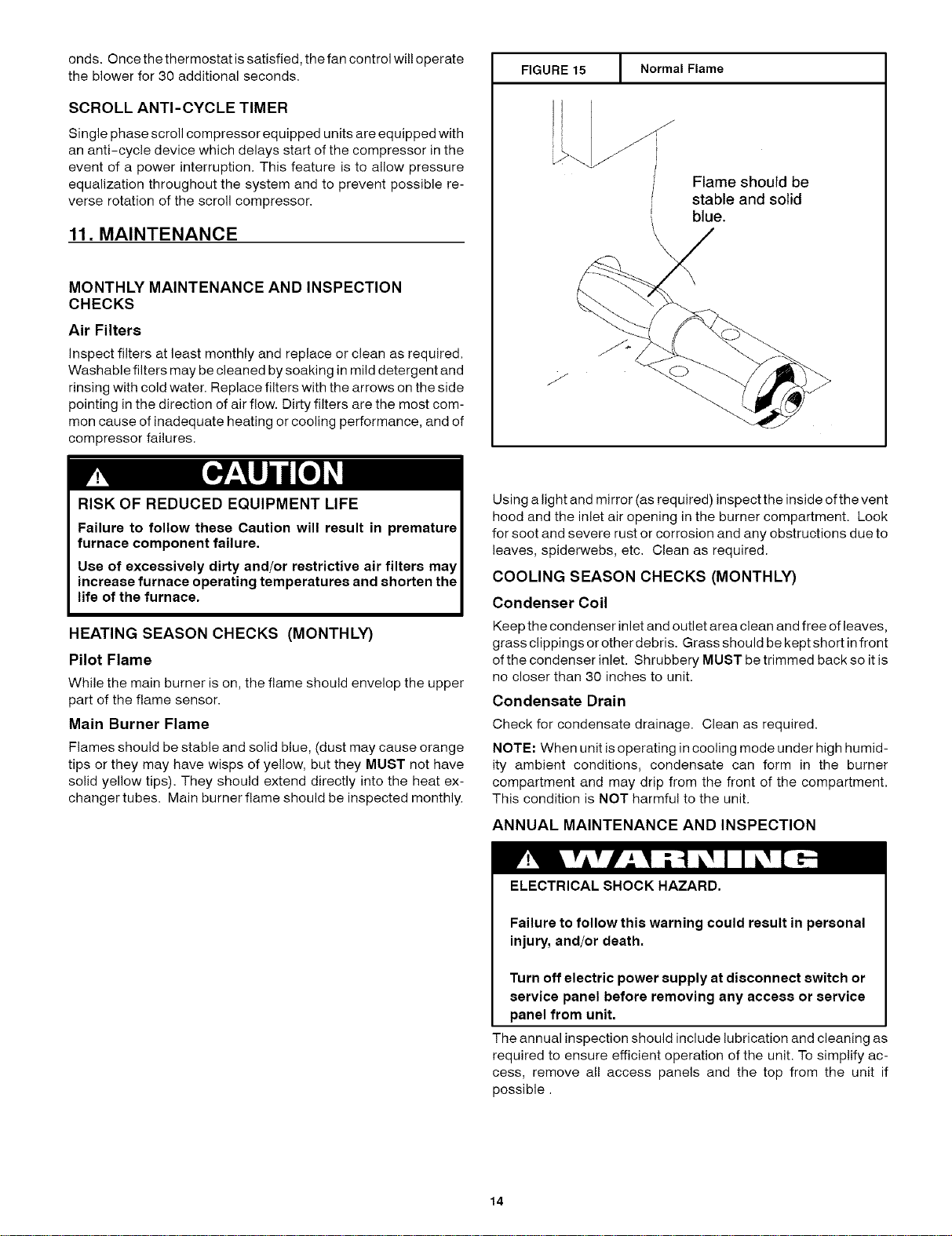

FIGURE 15 1 Normal Flame

Flame should be

stable and solid

blue.

RISK OF REDUCED EQUIPMENT LIFE

Failure to follow these Caution will result in premature

furnace component failure.

Use of excessively dirty and/or restrictive air filters may

increase furnace operating temperatures and shorten the

life of the furnace.

HEATING SEASON CHECKS (MONTHLY)

Pilot Flame

While the main burner is on, the flame should envelop the upper

part of the flame sensor.

Main Burner Flame

Flames should be stable and solid blue, (dust may cause orange

tips or they may have wisps of yellow, but they MUST not have

solid yellow tips). They should extend directly into the heat ex-

changer tubes. Main burner flame should be inspected monthly.

Using a light and mirror (as required) inspect the inside of the vent

hood and the inlet air opening in the burner compartment. Look

for soot and severe rust or corrosion and any obstructions due to

leaves, spiderwebs, etc. Clean as required.

COOLING SEASON CHECKS (MONTHLY)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of leaves,

grass clippings or other debris. Grass should be kept short in front

of the condenser inlet. Shrubbery MUST be trimmed back so it is

no closer than 30 inches to unit.

Condensate Drain

Check for condensate drainage. Clean as required.

NOTE: When unit is operating in cooling mode under high humid-

ity ambient conditions, condensate can form in the burner

compartment and may drip from the front of the compartment.

This condition is NOT harmful to the unit.

ANNUAL MAINTENANCEANDINSPECTION

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, and/or death.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

The annual inspection should include lubrication and cleaning as

required to ensure efficient operation of the unit. To simplify ac-

cess, remove all access panels and the top from the unit if

possible.

14

Loading ...

Loading ...

Loading ...