Loading ...

Loading ...

Loading ...

8. DUCTWORK

Maximum recommended velocity in trunk ducts is 1000 feet per

minute. Velocity in branches should not exceed 800 feet per min-

ute.

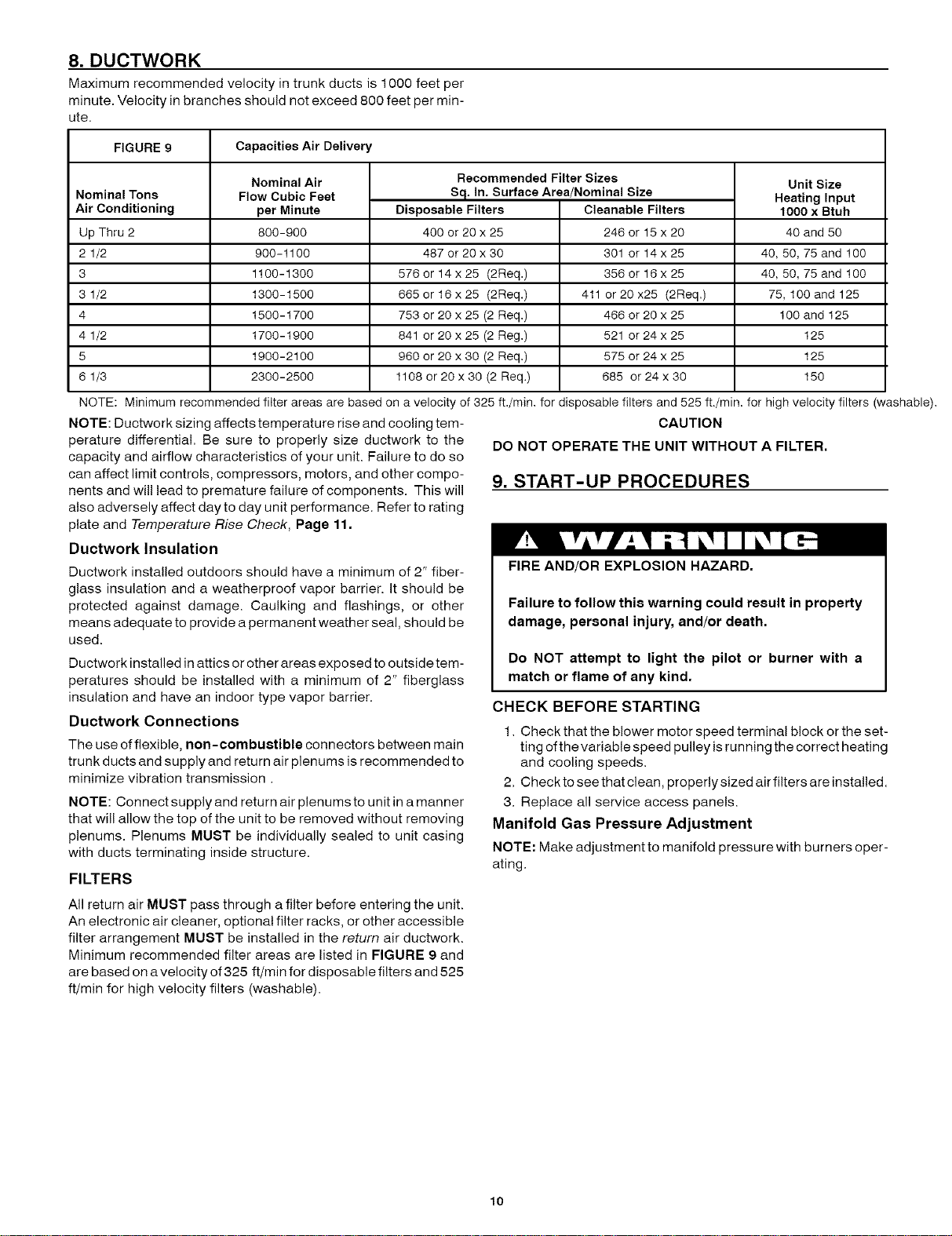

FIGURE 9 Capacities Air Delivery

Nominal Tons

Air Conditioning

Up Thru 2

2 1/2

3

3 1/2

4

4 1/2

5

6 1/3

Nominal Air

Flow Cubic Feet

per Minute

800-900

900-1100

1100-1300

1300-1500

1500-1700

1700-1900

1900-2100

2300-2500

Recommended Filter Sizes

Sq. In. Surface Area/Nominal Size

Disposable Filters Cleanable Filters

400 or 20 x 25 246 or 15 x 20

487 or 20 x 30 301 or 14 x 25

576 or 14x25 (2Req.) 356 or 16x25

665 or 16 x 25 (2Req.) 411 or 20 x25 (2Req.)

753 or 20 x 25 (2 Req.) 466 or 20 x 25

841 or 20 x 25 (2 Reg.) 521 or 24 x 25

960 or 20 x 30 (2 Req.) 575 or 24 x 25

1108 or 20 x 30 (2 Req.) 685 or 24 x 30

Unit Size

Heating Input

1000 x Btuh

40 and 50

40, 50, 75 and 100

40, 50, 75 and 100

75, 100 and 125

100 and 125

125

125

150

NOTE: Minimum recommended filter areas are based on a velocity of 325 ft./min, for disposable filters and 525ft./min, for high velocity filters (washable).

NOTE: Ductwork sizing affects temperature rise and cooling tem- CAUTION

perature differential. Be sure to properly size ductwork to the DO NOT OPERATE THE UNIT WITHOUT A FILTER,

capacity and airflow characteristics of your unit. Failure to do so

can affect limit controls, compressors, motors, and other compo- 9, START-UP PROCEDURES

nents and will lead to premature failure of components. This will

also adversely affect day to day unit performance. Refer to rating

plate and Temperature Rise Check, Page 11.

Ductwork Insulation

Ductwork installed outdoors should have a minimum of 2" fiber-

glass insulation and a weatherproof vapor barrier. It should be

protected against damage. Caulking and flashings, or other

means adequate to provide a permanent weather seal, should be

used.

Ductwork installed in attics or other areas exposed to outside tem-

peratures should be installed with a minimum of 2" fiberglass

insulation and have an indoor type vapor barrier.

Ductwork Connections

The use of flexible, non-combustible connectors between main

trunk ducts and supply and return air plenums is recommended to

minimize vibration transmission.

NOTE: Connect supply and return air plenums to unit in a manner

that will allow the top of the unit to be removed without removing

plenums. Plenums MUST be individually sealed to unit casing

with ducts terminating inside structure.

FILTERS

FIRE AND/OR EXPLOSION HAZARD.

Failure to follow this warning could result in property

damage, personal injury, and/or death.

Do NOT attempt to light the pilot or burner with a

match or flame of any kind.

CHECK BEFORE STARTING

1. Check that the blower motor speed terminal block or the set-

ting ofthevariable speed pulley isrunning the correct heating

and cooling speeds.

2. Checktoseethatclean, properlysizedairfiltersareinstalled.

3. Replace all service access panels.

Manifold Gas Pressure Adjustment

NOTE: Make adjustment to manifold pressure with burners oper-

ating,

All return air MUST pass through a filter before entering the unit.

An electronic air cleaner, optional filter racks, or other accessible

filter arrangement MUST be installed in the return air ductwork.

Minimum recommended filter areas are listed in FIGURE 9 and

are based on a velocity of 325 ff/min for disposable filters and 525

ft/min for high velocity filters (washable).

10

Loading ...

Loading ...

Loading ...