Loading ...

Loading ...

Loading ...

obtained when the unit is operating at rated input with the recom-

mended blower speed.

1. The temperature rise must be within the specifications

marked on the unit rating plate.

To check the temperature rise through the unit, place ther-

mometers in the supply and return air ducts as close to the

unit as possible.

Open ALL registers and duct dampers. Operate unit AT

LEAST 15 minutes before taking readings.

Ifthe correct amount of temperature rise is not obtained when op-

erating on the recommended blower speed, it may be necessary

to change the blower speed. A faster blower speed will decrease

the temperature rise. A slower blower speed wil! increase the tem-

perature rise.

NOTE; The blower speed MUST be set to give the correct air tem-

perature rise through the furnace as marked on the rating plate.

See FIGURE 14 for more information.

2. After 15 minutes of operation check the limit control function

by blocking the

return air grille(s).

After several minutes the main burners and pilot should go

OFE The circulating air blower should continue to run.

Remove air restrictions. Pilot and main burners should

relight after a cool down period of a few minutes.

3. Adjust the thermostat setting below room temperature.

Pilot and main burners and combustion air blower should go

OFE

The circulating air blower should continue to run for 60, 100,

140 or 180 seconds. This time isadjustable. See Figure 14

for more information.

4. Set thermostat Heat-Cool selector to OFF

FAN CONTROL CHECK

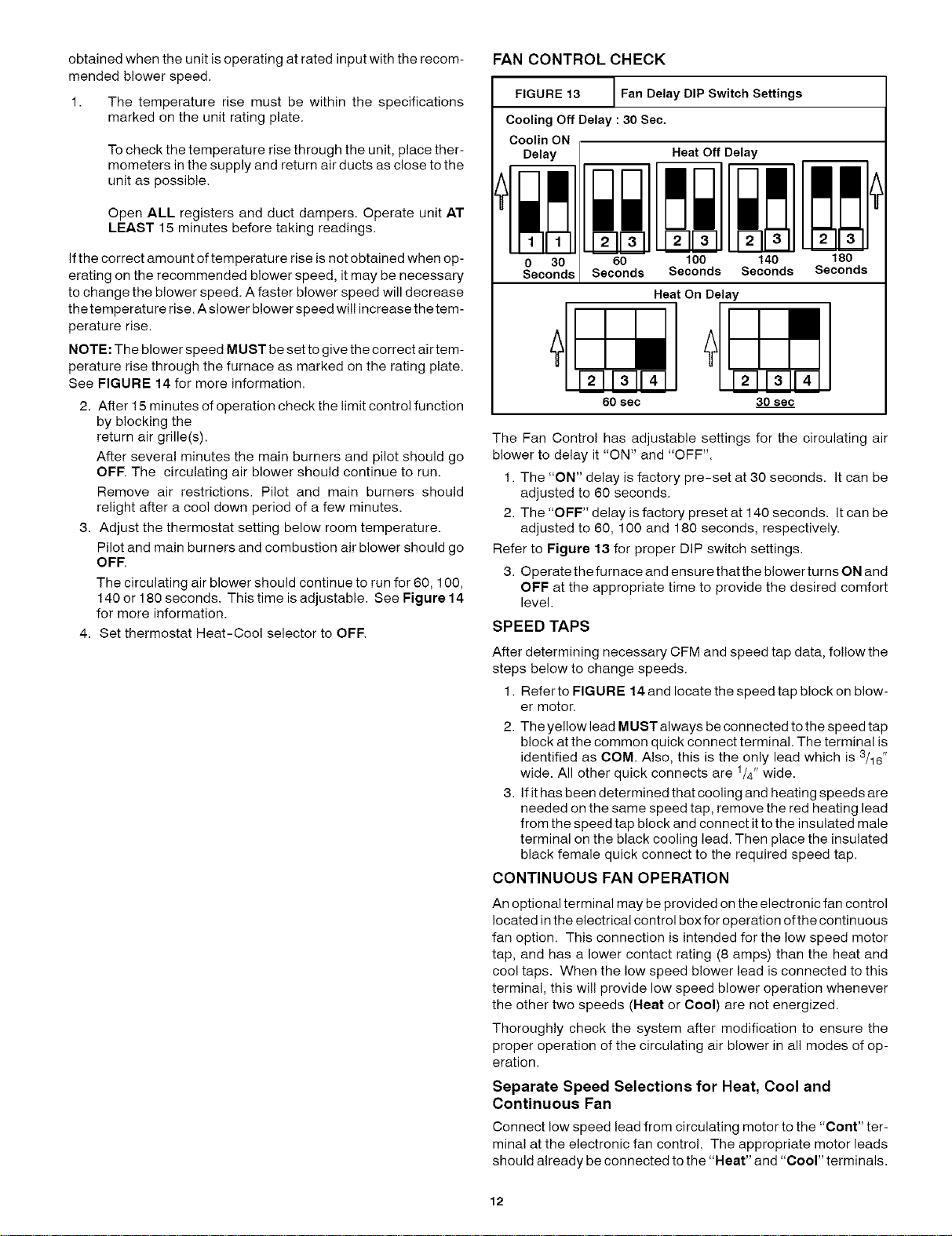

FIGURE 13 J Fan Delay DIP Switch Settings

Cooling Off Delay : 30 Sec.

Coolin ON

Delay Heat Off Delay

0 30

Seconds

60 100 140

Seconds Seconds Seconds

180

Seconds

Heat On Delay

MMM DDbJ

60 sec 30 sec

The Fan Control has adjustable settings for the circulating air

blower to delay it "ON" and "OFF".

1. The "ON" delay is factory pre-set at 30 seconds. It can be

adjusted to 60 seconds.

2. The "OFF" delay is factory preset at 140 seconds. It can be

adjusted to 60, 100 and 180 seconds, respectively.

Refer to Figure 13 for proper DIP switch settings.

3. Operate the furnace and ensure that the blower turns ON and

OFF at the appropriate time to provide the desired comfort

level.

SPEED TAPS

After determining necessary CFM and speed tap data, follow the

steps below to change speeds.

1. Refer to FIGURE 14 and locate the speed tap block on blow-

er motor.

2. The yellow lead MUST always be connected to the speed tap

block at the common quick connect terminal. The terminal is

identified as COM. Also, this is the only lead which is 3/16"

wide. All other quick connects are 1/4" wide.

3. If it has been determined that cooling and heating speeds are

needed on the same speed tap, remove the red heating lead

from the speed tap block and connect it to the insulated male

terminal on the black cooling lead. Then place the insulated

black female quick connect to the required speed tap.

CONTINUOUS FAN OPERATION

An optional terminal may be provided on the electronic fan control

located in the electrical control box for operation ofthe continuous

fan option. This connection is intended for the low speed motor

tap, and has a lower contact rating (8 amps) than the heat and

cool taps. When the low speed blower lead is connected to this

terminal, this will provide low speed blower operation whenever

the other two speeds (Neat or Cool) are not energized.

Thoroughly check the system after modification to ensure the

proper operation of the circulating air blower in all modes of op-

eration.

Separate Speed Selections for Heat, Cool and

Continuous Fan

Connect low speed lead from circulating motor to the "Cont" ter-

minal at the electronic fan control. The appropriate motor leads

should already be connected to the "Heat" and "Cool" terminals.

12

Loading ...

Loading ...

Loading ...