Loading ...

Loading ...

Loading ...

_vlvh_=1_[I

To avoid injury from an accidental start, ALWAYS

make sure the switch is in the "OFF" position, the

switch key is removed, and the plug is not connected

to the power source outlet before making belt

adjustments.

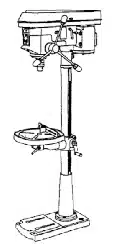

ALIGNING THE BELT PULLEYS (FIG. N)

Open the head cover of the Drill Press. Check

alignment of the pulleys with a straight edge (5) such

as a framimg square, a level, or a piece of a wood.

Lay the straight edge across the top of the pulleys. If

all three pulleys are NOT aligned:

1. Release belt pressure by loosening the belt tension

lock knobs (4) on either side of the head, unlocking

the belt tension handle (1).

2. Loosen the motor mount nuts (2). Lift or lower the

motor (3) until the pulleys are in line.

3. Tighten the motor mount nuts (2) using an

adjustable wrench.

NOTE: To avoid rattles or other noise, the motor

housing should not touch the lower belt guard

housing.

4. Retighten the belts by turning the belt tension

handle (1) clockwise, until the belt deflects

approximately 1/2 inch when pressed in the center.

NOTE: Refer to the chart inside the belt guard

cover for recommended drilling speeds and

belt/pulley positions.

5. Lock the belt tension lock knobs (4) by turning

clockwise.

NOTE: When the belts are new, it may be difficult to

move the belts. As the machine is used, the belts will

gain more elasticity and will be easier to adjust.

Fig. Q

BASIC DRILL PRESS OPEATIONS

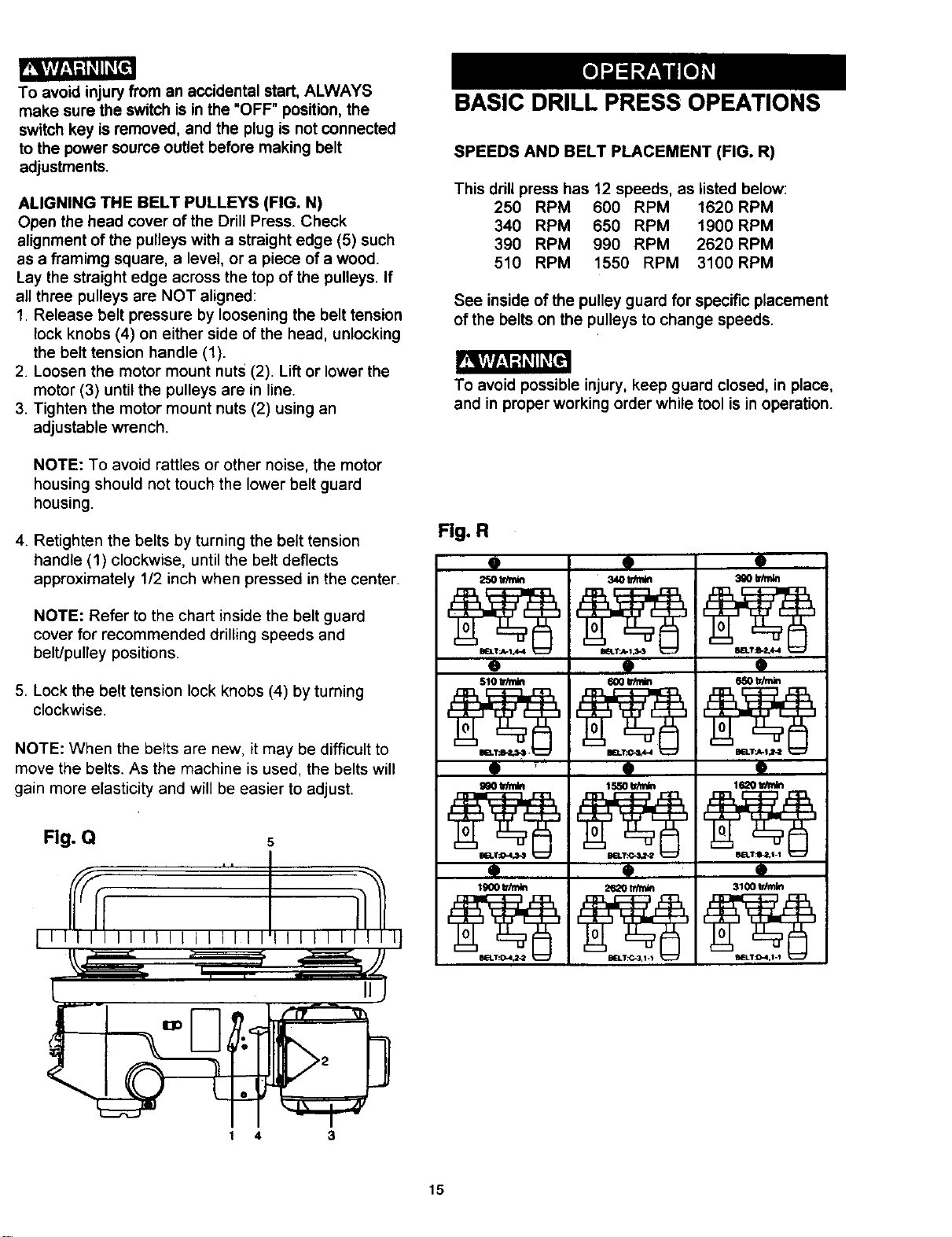

SPEEDS AND BELT PLACEMENT (FIG. R)

This drill press has 12 speeds, as listed below:

250 RPM 600 RPM 1620RPM

340 RPM 650 RPM 1900RPM

390 RPM 990 RPM 2620 RPM

510 RPM 1550 RPM 3100RPM

See inside of the pulley guard for specific placement

of the belts on the pulleys to change speeds.

To avoid possible injury, keep guard closed, in place,

and in proper working order while tool is in operation.

Fig. R

9

250 trim_

o

510 tdmin

i

9

9

9

9

9

9

Q

9

9

3100 tr_lin

1 4 3

15

Loading ...

Loading ...

Loading ...